How to Select the Right Plate Heat Exchanger Gasket Material for Your Application: A Comprehensive Guide by YIIING MACEINFRY

The Critical Role of Gaskets in Plate Heat Exchanger Performance and Selection

In the world of industrial heat transfer, the efficiency and reliability of a plate heat exchanger often hinge on a component that doesn't get the spotlight: the gasket. While plates from manufacturers like Alfa Laval plate heat exchangers, Tranter plate heat exchangers, and Sondex plate heat exchangers are engineered for optimal thermal performance, the gasket is the unsung hero ensuring leak-proof operation and media integrity. For engineers and procurement specialists, selecting the correct plate heat exchanger gaskets is not a minor detail—it's a decision that impacts maintenance schedules, operational safety, and total cost of ownership.

This guide, brought to you by YIIING MACEINFRY from Jiangsu Yuling Machinery Technology Co., Ltd., will walk you through the key factors in choosing the right gasket material, helping you avoid common pitfalls and maximize the lifespan of your detachable plate heat exchanger.

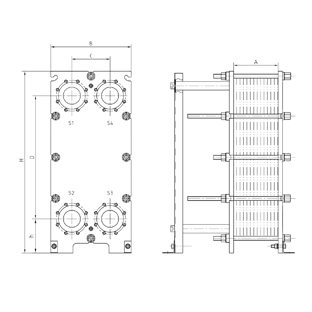

A detachable plate heat exchanger, showcasing the plates and gasket grooves. Proper gasket selection is vital for its performance.

Understanding Gasket Function and Installation Types

Before diving into materials, it's crucial to understand how gaskets work in a plate heat exchanger. They sit in the grooves around the perimeter of each plate heat exchanger plate, creating a seal between plates to prevent fluid mixing and leakage to the environment. For detachable plate heat exchangers, gaskets are typically installed using one of three methods:

- Adhesive: Glued into the plate groove. Common but requires careful cleaning during regasketing.

- Embedded (Snap-in): A groove design allows the gasket to snap into place without adhesive, speeding up maintenance.

- Hook (Clip-on): Uses a mechanical clip system, offering very fast plate assembly and disassembly.

Companies like APV plate heat exchangers, GEA plate heat exchangers, and SWEP plate heat exchangers often have proprietary gasket designs. As a versatile manufacturer, Yuling (YIIING MACEINFRY) provides compatible solutions and expert guidance on the best fit for your operation.

The Core Decision: Matching Gasket Material to Process Fluid

The single most important factor in gasket selection is chemical compatibility with the process fluids. An incorrect choice can lead to rapid swelling, shrinkage, hardening, or chemical degradation, causing leaks and unplanned downtime.

Gasket Material Selection Guide

Here is a breakdown of common gasket materials, their temperature limits, and typical applications—a knowledge base we apply daily at our Yuling Thermal Energy Technology Research Institute.

1. Nitrile Rubber (NBR)

Temperature Range: -15°C to 130°C

Best For: Water, sea water, mineral oils, brines, and many hydraulic fluids.

Considerations: NBR is a cost-effective, general-purpose elastomer with good resistance to oils and fats. It's a standard choice for many cooling water and lubricating oil applications in industries served by API plate heat exchangers and Hisaka plate heat exchangers.

2. Hydrogenated Nitrile Butadiene Rubber (HNBR)

Temperature Range: -15°C to 160°C

Best For: High-temperature mineral oils, hot water, and systems requiring better heat and chemical resistance than standard NBR.

Considerations: HNBR offers superior resistance to oxidation, heat, and abrasion. It's an excellent upgrade for demanding applications where standard NBR might age prematurely.

3. Ethylene Propylene Diene Monomer (EPDM)

Temperature Range: -25°C to 180°C

Best For: Hot water, steam, alkalis, mild acids, alcohols, and phosphate ester fluids. It has excellent resistance to weathering and ozone.

Considerations: EPDM gaskets are the go-to choice for district heating, solar thermal systems, and many chemical processes. CRITICAL NOTE: EPDM has very poor resistance to petroleum-based oils and fuels. Never use it in hydrocarbon service.

4. Fluorocarbon Rubber (FKM/Viton)

Temperature Range: -5°C to 180°C

Best For: Strong acids, alkalis, aromatic hydrocarbons, and aggressive chemicals.

Considerations: FKM offers the broadest chemical resistance among common elastomers. It is ideal for challenging chemical processing, pharmaceutical, and refining applications. It is, however, more expensive and has limited resistance to steam and hot water compared to EPDM.

Precision manufacturing in Yuling's workshop ensures consistent quality for every plate heat exchanger component.

Beyond Material: Other Key Selection Factors

While fluid compatibility is king, other factors play a significant role:

- Temperature & Pressure: Always consider the maximum and minimum operating temperatures. Cyclic thermal stress can fatigue gaskets. Ensure the material's rating exceeds your process limits.

- Cleaning & Maintenance Regime: If you frequently clean plates with aggressive chemicals (e.g., strong acids for descaling), the gasket must withstand these cleaning cycles. EPDM or FKM are often required here.

- Food, Pharma, and Potable Water Standards: For applications in food (like dairy or beverage processing where plate heat exchangers originated), pharmaceuticals, or drinking water, you must select gaskets compliant with FDA, EC1935/2004, NSF/ANSI 61, or other relevant standards. Special compound grades are available.

- Plate Material Compatibility: The gasket material must also be compatible with the plate heat exchanger plates material (e.g., stainless steel SUS304/316L, titanium, Hastelloy) to avoid galvanic or crevice corrosion issues.

YIIING MACEINFRY's Expertise and Quality Assurance

At Jiangsu Yuling Machinery Technology Co., Ltd., we don't just sell plate heat exchangers; we provide engineered solutions. Our technical team can analyze your specific process conditions—whether you need a detachable plate heat exchanger for easy cleaning, a compact brazed plate heat exchanger for high pressure, or a robust fully-welded plate heat exchanger for challenging fluids—and recommend the optimal plate and gasket combination.

Our commitment to quality is underpinned by international certifications, ensuring every product meets the highest standards:

ISO 9001:2015

Quality Management

ISO 45001:2018

Occupational Health & Safety

ISO 14001:2015

Environmental Management

Conclusion: Partner with a Knowledgeable Supplier

Selecting the right plate heat exchanger gaskets is a technical decision with long-term consequences. Instead of viewing them as a generic spare part, treat them as a critical system component. Partnering with an experienced manufacturer like Yuling (YIIING MACEINFRY) gives you access to deep application knowledge, high-quality compatible products, and reliable after-sales support.

Whether you are maintaining an existing unit from Alfa Laval, Tranter, or Sondex, or specifying a new, cost-effective plate heat exchanger for your project, we are here to help. Visit our website to explore our full range of heat exchange solutions or contact our engineering team for a personalized consultation.

Contact YIIING MACEINFRY / Jiangsu Yuling Machinery Technology Co., Ltd. Today:

📞 Tel: +86 513 8836 0268

📱 WhatsApp: +86 13813790595

📧 Email: info@yuling-machine.com

🌐 Website: www.yuling-phe.com

📍 Address: No.169, Lifa Avenue, Haian City, Jiangsu Province, China