▪ Bespoke engineered continuous drying solution to fit your requirements

▪ Continuous and gentle drying preserving maximum colour, flavour and composition, and minimal oxidation

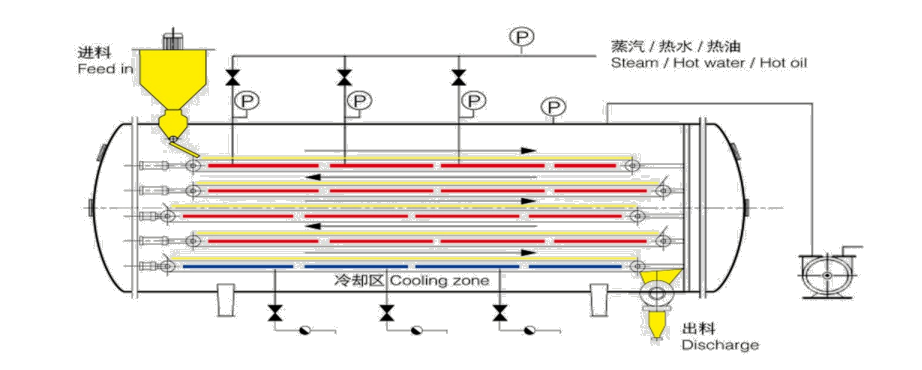

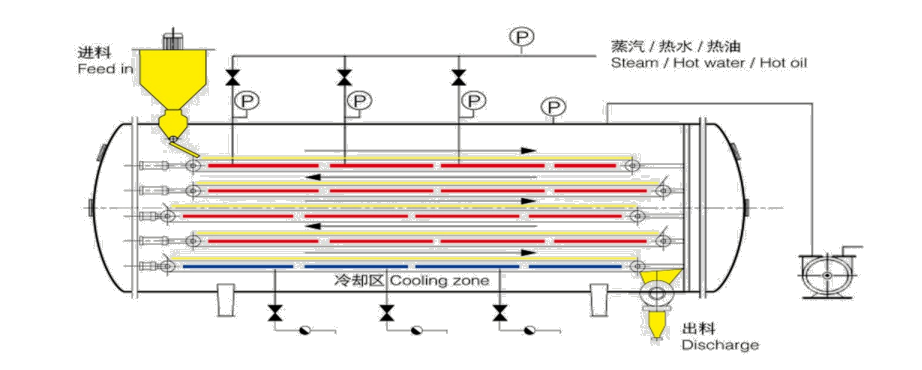

▪ Individual temperature zones allow for product-specific profiles to be developed suited to each perfectly to each product

▪ Less energy used than other drying methods

▪ Viewing windows as standard allow for continuous monitoring, with options for automated monitoring systems available

▪ Product specific feeding and discharging systems

▪ Fully PLC automated operation & CIP cleaning system

▪ GMP standards

Equipment Specification:

| Model |

Diameter |

Length |

Height |

Heating area |

Heating temperature |

Moisture content of feeding material |

Moisture contentof dried product |

Heating

resource

|

Water Evaporation |

Dryer

Body

Power

|

| |

mm |

mm |

mm |

㎡ |

℃ |

% |

% |

|

kg/h |

kw |

| MJG15-3 |

1400 |

7500 |

3000 |

15 |

20-150 |

10-80 |

0.3-5 |

Steam or Hot

water or Hot oil

|

8-12 |

6.00 |

| MJG35-5 |

1600 |

9800 |

3300 |

35 |

18-25 |

8.00 |

| MJG50-5 |

2200 |

11500 |

3800 |

50 |

25-35 |

12.00 |

| MJG70-5 |

2200 |

13500 |

3800 |

70 |

35-45 |

12.00 |

| MJG80-5 |

2200 |

15500 |

3800 |

80 |

40-60 |

12.00 |

| MJG120-7 |

2300 |

16000 |

4200 |

120 |

70-90 |

15.00 |

| MJG160-9 |

2500 |

16000 |

4500 |

160 |

90-120 |

17.00 |

| MJG220-11 |

2800 |

16000 |

4500 |

200 |

120-150 |

19.00 |

If the solvent of raw material is organic (ethanol, acetone, methanol etc.),evaporationcapacity would rise. Evaporation capacity is closely related with drying temperature.

— WHY CHOOSE MINJIE —

A company specialized in research, manufacturing, sales of pharmaceutical, foodstuff, chemical and biotechnology machinery.

- The first factory in China to produce Vacuum Belt Dryer(VBD)

- Developed the first set of Energy-saving Evaporator in China

- 20 years experience in VBD and Evaporator Solution production line

- Rich experience in overseas export and service (over 500 cooperative partners)

- Win large market (over 700 sets Minjie series VBD around the world)

- Supply ability is more than 100 sets VBD per year

- Has a professional technical R&D team,specialized in researching and developing advanced evaporator and drying equipment

- Own many patents and authentication certificates for VBD and Evaporator

- Excellent quality of the products

- GMP standards

- Technical support After-sales Service Provided (Installation instructions, Commissioning, Training)

25,000 square meterstion, with 22,600 square meters.

25,000 square meterstion, with 22,600 square meters.

Over 250 employees 15 senior engineers, 32 engineers, and 55 skilled technicians.

ISO/CE/GMP

Over 250 employees 15 senior engineers, 32 engineers, and 55 skilled technicians.

ISO/CE/GMP