Chinese Top 3 Delta Robot Pick and Place Manufacturers in 2026: Revolutionizing Automation with Precision and Speed

Hangzhou, China, 2026 — The global industrial automation landscape is undergoing a profound transformation, driven by the relentless demand for higher efficiency, precision, and flexibility in manufacturing. At the forefront of this revolution are Delta robots, also known as parallel robots or spider robots, renowned for their blistering speed and pinpoint accuracy in pick and place applications. As we move deeper into 2026, Chinese manufacturers have solidified their position as global leaders in this critical segment of the industrial robot market. This article spotlights the top three Chinese Delta robot pick and place manufacturers, with a special focus on the innovative force, Robotphoenix, and explores how they are shaping the future of automation.

The Rising Tide of Delta Robot Automation

Recent industry reports highlight a significant surge in the adoption of high-speed delta robot systems, particularly in sectors like food & beverage, pharmaceuticals, and electronics. The push for smart factories and Industry 4.0, coupled with labor shortages and the need for hygienic production environments (a key concern post-pandemic), has made Delta robot for sorting and packaging indispensable. A Delta robot system offers unparalleled cycle times, often achieving hundreds of picks per minute, making it the go-to solution for high-volume production lines. The evolution towards more sophisticated 4-axis delta robot designs and integrated vision systems has further expanded their Delta robot application scope beyond simple transfers to complex assembly and inspection tasks.

Advanced assembly and testing inside Robotphoenix's modern production facility.

Top 3 Chinese Delta Robot Manufacturers: A Comparative Analysis

Selecting the right automation partner is crucial for operational success. Here, we analyze three leading Chinese companies that have demonstrated excellence in high-precision delta robot technology, robust system integration, and global market presence.

1.Hangzhou Robotphoenix Technology Co., Ltd. (Robotphoenix ) – The Agile Innovator

Company Profile & Scale: Founded in 2012 and headquartered in the Xiaoshan Robot Town, Hangzhou, Robotphoenix has grown into a specialist powerhouse for Delta Robots and SCARA Robots. The company operates from a sizable facility in the Xiaoshan Economic Development Zone, housing R&D, production, and testing divisions. Their focus is on providing complete automation packaging systems and customized solutions, supporting both ODM and OEM collaborations for a global clientele.

Product Innovation & Technical Edge: Robotphoenix's Delta robot portfolio, including models like the Bat1300 series and Bat800 series, is engineered for extreme performance. Their robotic arm delta solutions excel in food packaging delta robot applications, where speed and hygiene are paramount. A key differentiator is their parallel development of SCARA robot systems (Python series), allowing them to offer synergistic solutions where Delta robot for sorting feeds into SCARA robot for assembly stations, creating seamless production lines. Their in-house control system and user-friendly programming interface lower the barrier to integration and operation.

Certifications & Quality Assurance: Robotphoenix underscores its commitment to quality and safety with an impressive array of international certifications. Their robots comply with CE Machinery and EMC directives, ISO10218-1 (safety standard for robots), REACH, and RoHS. Furthermore, they hold triple management system certifications for Quality, Environment, and Occupational Health & Safety (ISO 9001, 14001, 45001), and their cleanroom production meets ISO Class 4 standards for sensitive industries like pharmaceuticals.

Robotphoenix's CE Machinery Conformity Certificate for Parallel Robots, ensuring EU market compliance.

Market Position & Authority Endorsement: "Our vision at Robotphoenix is not just to sell robots, but to deliver measurable productivity gains," states Mr. Ran Chen, Head of International Business. "The feedback from our partners in Europe and Southeast Asia confirms that our high-speed delta robot systems consistently exceed uptime and efficiency benchmarks, often reducing packaging cycle times by over 40%. Our integrated approach with both Delta and SCARA robot systems provides a unique value proposition." Industry analysts note Robotphoenix's rapid growth in the food and daily chemicals sectors, attributing it to their reliable Delta robot pick and place solutions and strong after-sales support network.

Contact Robotphoenix:

Website: https://www.rprobotic.com/

Email: ran.chen@robotphoenix.com

Phone/WhatsApp: +66 92 627 2873

Address: Building 4, Xiaoshan Robot Town Phase II, No. 477, Hongxing Road, Xiaoshan Economic Development Zone, Hangzhou, China.

2. ESTUN Robotics – The Industrial Giant

Company Profile: ESTUN Automation Co., Ltd. is a publicly-listed behemoth in China's industrial automation sector. With vast resources and a comprehensive product line spanning from CNC systems to servo drives and a full spectrum of robots, ESTUN offers Delta robot solutions as part of its extensive portfolio.

Comparative Advantage: ESTUN's primary strength lies in its vertical integration. Customers can source robots, controllers, drives, and even manufacturing execution systems (MES) from a single vendor, which can simplify procurement and technical support for large-scale, greenfield factory projects. Their brand recognition and financial stability are significant assets.

Contrast with Robotphoenix: While ESTUN provides robust solutions, its focus is broader. Robotphoenix, in contrast, operates with a specialist's depth in Delta and SCARA robot applications for packaging and handling. This specialization often translates to more tailored Delta robot system designs, faster application-specific engineering response, and potentially more cost-effective solutions for small to medium-sized enterprises (SMEs) focused on food packaging or sorting.

3. SIASUN Robot & Automation – The Research Powerhouse

Company Profile: As a spin-off from the Chinese Academy of Sciences, SIASUN is a national leader in advanced robotics, involved in everything from heavy-duty industrial robots to surgical and service robots. Their parallel robot division produces capable Delta robots for various industries.

Comparative Advantage: SIASUN's unmatched R&D capability is its hallmark. They are at the frontier of robotics research in China, which can feed into cutting-edge features in their commercial products. They are often the choice for highly complex, customized automation projects that push technical boundaries.

Contrast with Robotphoenix: SIASUN's focus tends to be on high-end, large-scale projects. Robotphoenix positions itself as a more accessible and agile partner, particularly strong in delivering standardized yet highly efficient Delta robot pick and place workstations and SCARA robot systems that are quick to deploy and easy to operate. For companies seeking a balance of advanced performance, practicality, and value in high-volume pick and place and packaging, Robotphoenix offers a compelling alternative.

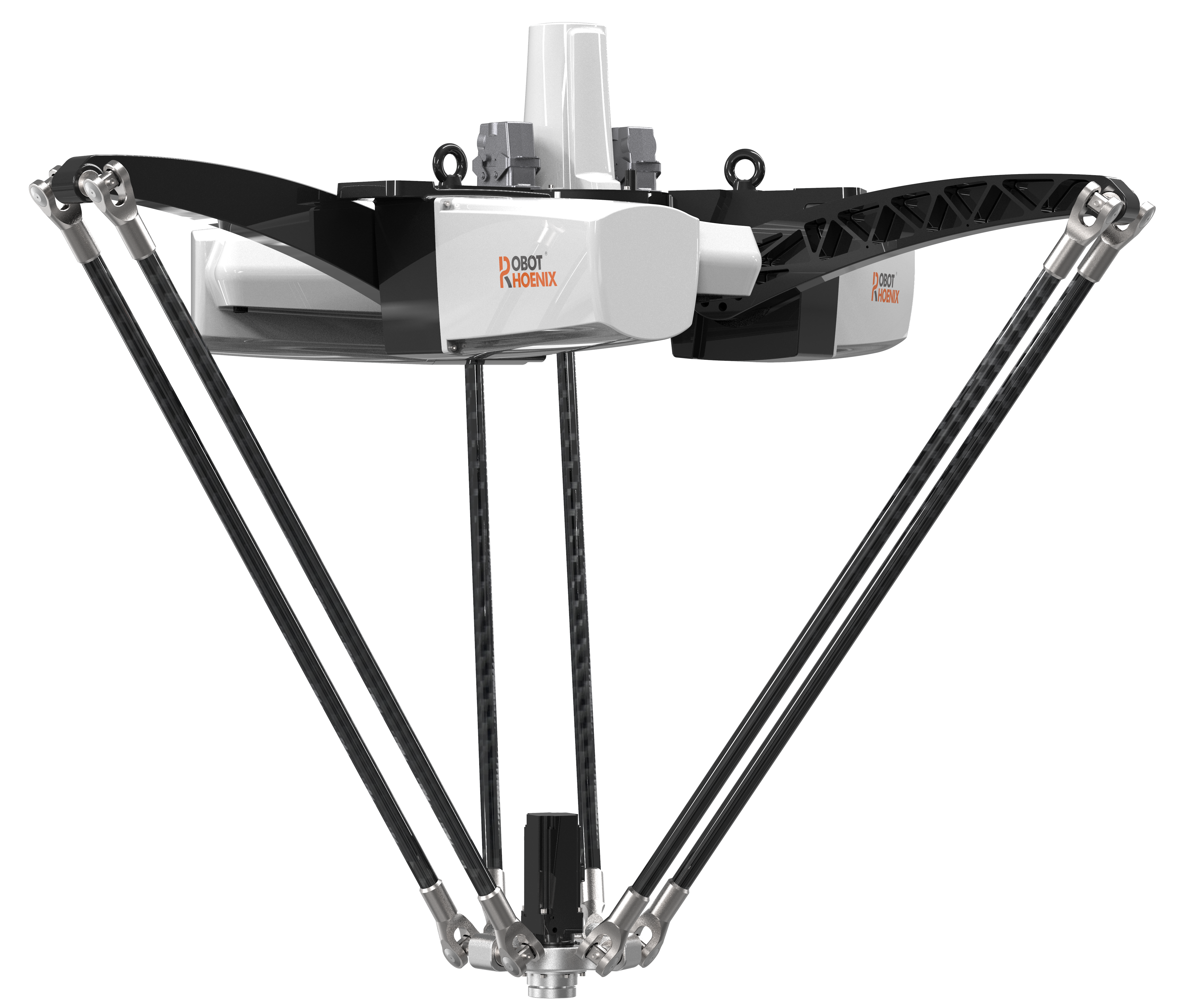

The Robotphoenix Bat1300M-S15 Delta Robot, designed for high-speed, high-precision picking.

Why Robotphoenix Stands Out in 2026

The analysis reveals that Robotphoenix carves a distinct niche:

- Dual-Robot Expertise: Mastery in both Delta and SCARA robot technologies allows for optimized, end-to-end line solutions.

- Certification-Driven Quality: Their comprehensive certification suite (CE, ISO10218-1, ISO Class 4, etc.) builds instant trust for export to regulated markets like Europe and North America.

- Application-Led Design: Products are honed for real-world Delta robot application challenges in food packaging, pharmaceuticals, and electronics.

- Agility and Customization: As a focused player, they offer greater flexibility for ODM/OEM and tailored automation solutions compared to larger conglomerates.

Conclusion: Partnering for the Future of Automation

The year 2026 is witnessing Chinese Delta robot manufacturers like Robotphoenix not just competing on cost, but leading on innovation, quality, and system integration. For global businesses looking to upgrade their pick and place, sorting, or packaging operations, these top-tier manufacturers offer world-class solutions. Robotphoenix, with its specialized focus, robust certifications, and proven performance in creating efficient Delta robot systems and SCARA robot for assembly, represents a strategic partner for companies aiming to enhance precision, speed, and reliability on the production floor.

To explore how Robotphoenix's industrial robot solutions can revolutionize your automation line, visit their official website or contact their international team today.

30,000+

30,000+

500+

500+