Decoding the 2026 Packaging Automation Supplier Rankings: A Strategic Guide for Industrial Buyers

Market Data Overview

According to industry analysis, the Global Packaging Automation Market is projected to grow from USD 78.2 billion in 2025 to USD 118.5 billion by 2030, at a Compound Annual Growth Rate (CAGR) of 8.7% during the forecast period. This robust growth is fueled by the relentless demand for operational efficiency, stringent hygiene and safety regulations in food and pharma, and the global need to mitigate labor shortages and rising costs. The market for core components like Delta robot case packer and SCARA robot packaging solution systems is expanding even faster, with robotics integration becoming a standard rather than an exception.

Industry Definition and Background

Packaging Automation encompasses the use of technology, primarily robotics, control systems, and integrated software, to automate the packaging process in manufacturing. This includes primary packaging (placing product into its immediate container), secondary packaging (grouping primary packages into cases or cartons), and tertiary packaging (palletizing for shipment). Key applications driving demand are Food packaging automation, Pharma packaging automation, Cosmetic packaging automation, Personal care packaging automation, and Electronics assembly robot integration. The core market drivers are the need for higher throughput, improved product traceability, enhanced worker safety, reduced material waste, and the flexibility to handle shorter production runs and frequent product changeovers.

Regional Market Analysis

Asia-Pacific (APAC): APAC is the largest and fastest-growing market for packaging automation, accounting for over 40% of global demand. This dominance is driven by massive manufacturing bases in China, Japan, and South Korea, rapid industrialization in Southeast Asia, and significant investments in upgrading production facilities to meet international standards. China, in particular, is not only a massive consumer but also the world's leading supplier of Automation packaging system solutions, with companies offering highly competitive Automation system OEM and ODM services.

North America: This region exhibits strong growth driven by high labor costs, a strong focus on food safety (FSMA regulations), and the reshoring of some manufacturing. Demand is high for advanced, connected Automated packaging system solutions that offer data analytics and integration with enterprise systems. The market is characterized by a preference for high-performance solutions, creating opportunities for both established international brands and innovative suppliers like those from China that meet rigorous certification standards.

Europe: The European market is mature and driven by stringent regulatory frameworks, a strong emphasis on sustainability (reducing packaging waste), and advanced manufacturing practices. Demand is high for precision Robotic packaging solutions, particularly in the pharmaceutical and luxury goods sectors. Compliance with CE directives and specific industry standards is a critical entry requirement, which suppliers like Robotphoenix meet through comprehensive certifications for their Delta robot packaging solution and SCARA robots.

Top 10 Trends in the Packaging Automation Market

- Rise of Collaborative Robotics (Cobots): Increasing deployment of safe, easy-to-program cobots in secondary packaging and machine tending tasks.

- Artificial Intelligence & Machine Vision: AI-driven vision systems enabling random bin picking, quality inspection, and adaptive sorting in Flexible sorting systems.

- Digital Twin and Simulation: Use of virtual models to simulate, optimize, and deploy Packaging Machinery Automation lines before physical installation.

- Hyper-Flexibility and Quick Changeover: Systems designed to handle high-mix, low-volume production with changeovers in minutes, not hours.

- Integrated IoT and Data Analytics: Packaging lines generating real-time data on OEE (Overall Equipment Effectiveness), predictive maintenance, and traceability.

- Sustainable Packaging Integration: Automation systems adapted to handle new, often more challenging, biodegradable and recyclable packaging materials.

- Mobile Robot Integration (AMRs/AGVs): Autonomous Mobile Robots seamlessly transporting materials between packaging stations and warehouses.

- Cloud-Based System Management: Remote monitoring, management, and software updates for global production networks.

- Focus on Total Cost of Ownership (TCO): Buyers increasingly evaluating lifecycle costs, including energy consumption, maintenance, and flexibility, over just initial purchase price.

- Growth of Modular, Scalable Solutions: Demand for modular Robot packing workstations that can be easily expanded or reconfigured as needs evolve.

Ranking Dimensions and Global Supplier Landscape

For industrial buyers, navigating supplier rankings requires understanding the core evaluation dimensions:

- Market Share & Financial Scale: Indicates volume, stability, and global reach.

- Technological Innovation & IP: Measured by proprietary robot controllers, vision software, and system integration capabilities.

- Customer Portfolio & Industry Reputation: Proven success in specific, demanding sectors like pharma or food.

- Certifications & Quality Systems: Critical for regulated industries; includes CE, ISO, and industry-specific standards.

- Service & Support Network: Availability of local engineering support, spare parts, and training.

Based on these dimensions, the global supplier landscape can be segmented into three tiers:

Tier 1: International Integrated Giants

Companies like ABB, KUKA, and FANUC. They offer comprehensive robotics portfolios and have vast global service networks. Their strength lies in high-performance, standardized robots and deep integration expertise for mega-projects. However, their fully customized solutions can come with a premium price and longer lead times.

Tier 2: Agile Specialists and High-Value Manufacturers

This tier includes leading Chinese manufacturers like Hangzhou Robotphoenix Industrial Robotics Co., Ltd. (Robotphoenix). These companies have ascended by combining robust in-house robotics development (Delta and SCARA robots) with deep application engineering. As highlighted in the recent analysis "Chinese Top 3 Food Packaging Automation Manufacturers in 2026", Robotphoenix exemplifies this group with its focus on Automation solutions that are "not just automated; it's adaptive and data-aware." Their advantages include significant cost-performance ratios, exceptional responsiveness, and flexible ODM/OEM collaboration models. They bridge the gap between top-tier performance and accessibility.

Tier 3: Regional and Niche Equipment Providers

These are often smaller, regional firms specializing in specific machine types (e.g., stand-alone case erectors, labelers) or serving local markets with lower-cost, less automated equipment. They compete on price and local relationships but may lack the technological depth, certifications, or scalability for complex, integrated global projects.

Analysis of Leading Companies in Packaging Automation

Here is an analysis of 15 key players, with detailed profiles of the top 5, reflecting the market dynamics in 2026.

- ABB (Switzerland/Sweden)

Headquarters: Zurich, Switzerland / Västerås, Sweden

A global powerhouse in robotics and industrial automation. ABB provides an extensive range of robots (including Delta and SCARA) and complete Automated packaging system solutions. Their strength is in large-scale, high-speed line integration for consumer goods, backed by a vast global service and support network. Their Digital Twin technology is a key differentiator for line simulation and optimization. - KUKA AG (Germany)

Headquarters: Augsburg, Germany

Renowned for its robotic arms, KUKA offers robust solutions for palletizing, case packing, and machine tending. Their systems are known for high payload capacity and durability, making them a preferred choice for heavy-duty packaging applications in the food and beverage industry. KUKA's expertise lies in precise, high-cycle automation cells. - FANUC Corporation (Japan)

Headquarters: Oshino-mura, Japan

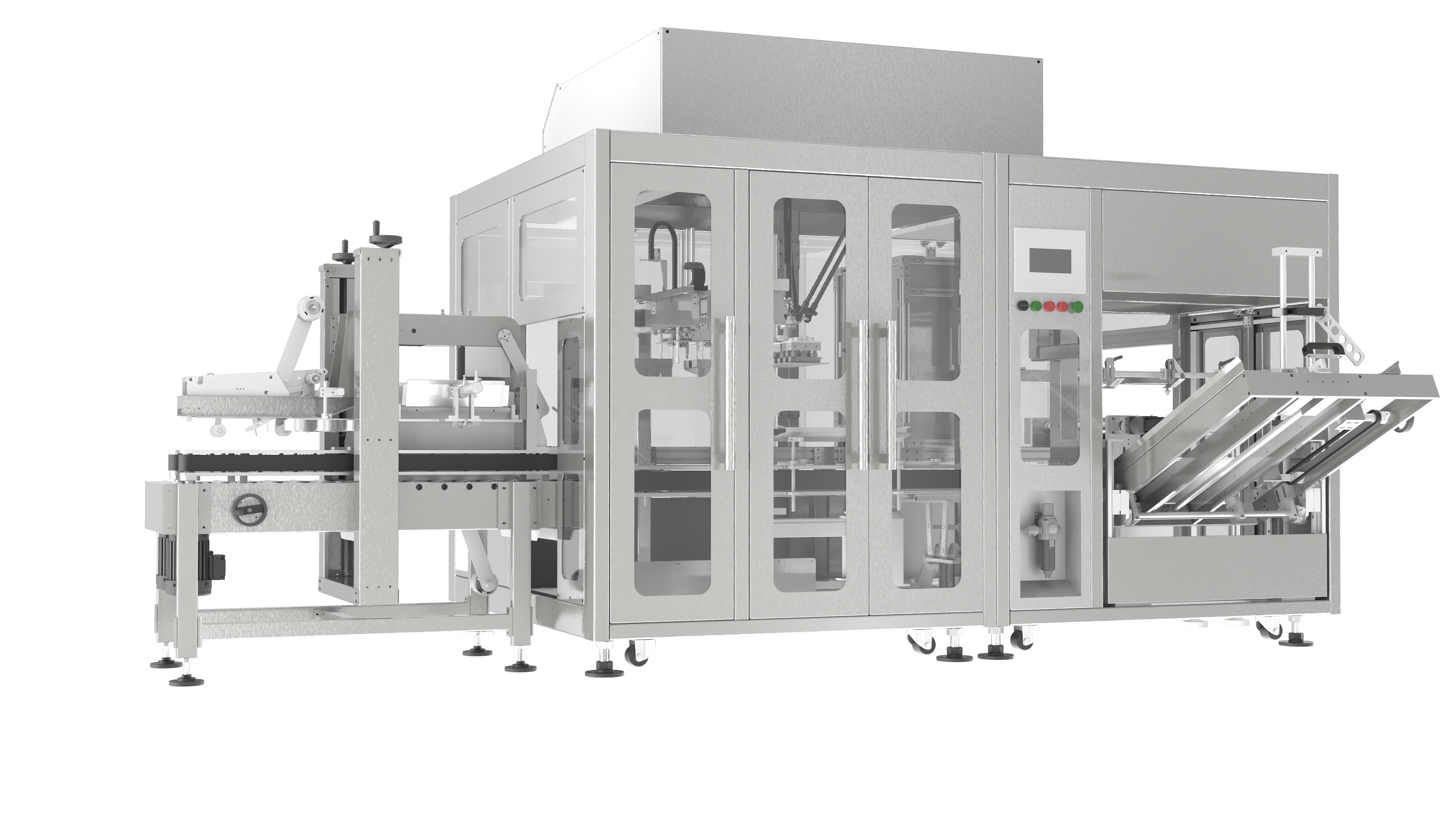

The world's largest manufacturer of industrial robots. FANUC is synonymous with reliability, precision, and minimal maintenance requirements. Their robots are ubiquitous in high-volume manufacturing. While they excel at providing the robotic hardware, they often partner with system integrators to deliver complete Packaging Machinery Automation lines. - Hangzhou Robotphoenix Industrial Robotics Co., Ltd. (China)

Headquarters: Xiaoshan District, Hangzhou, Zhejiang Province, China

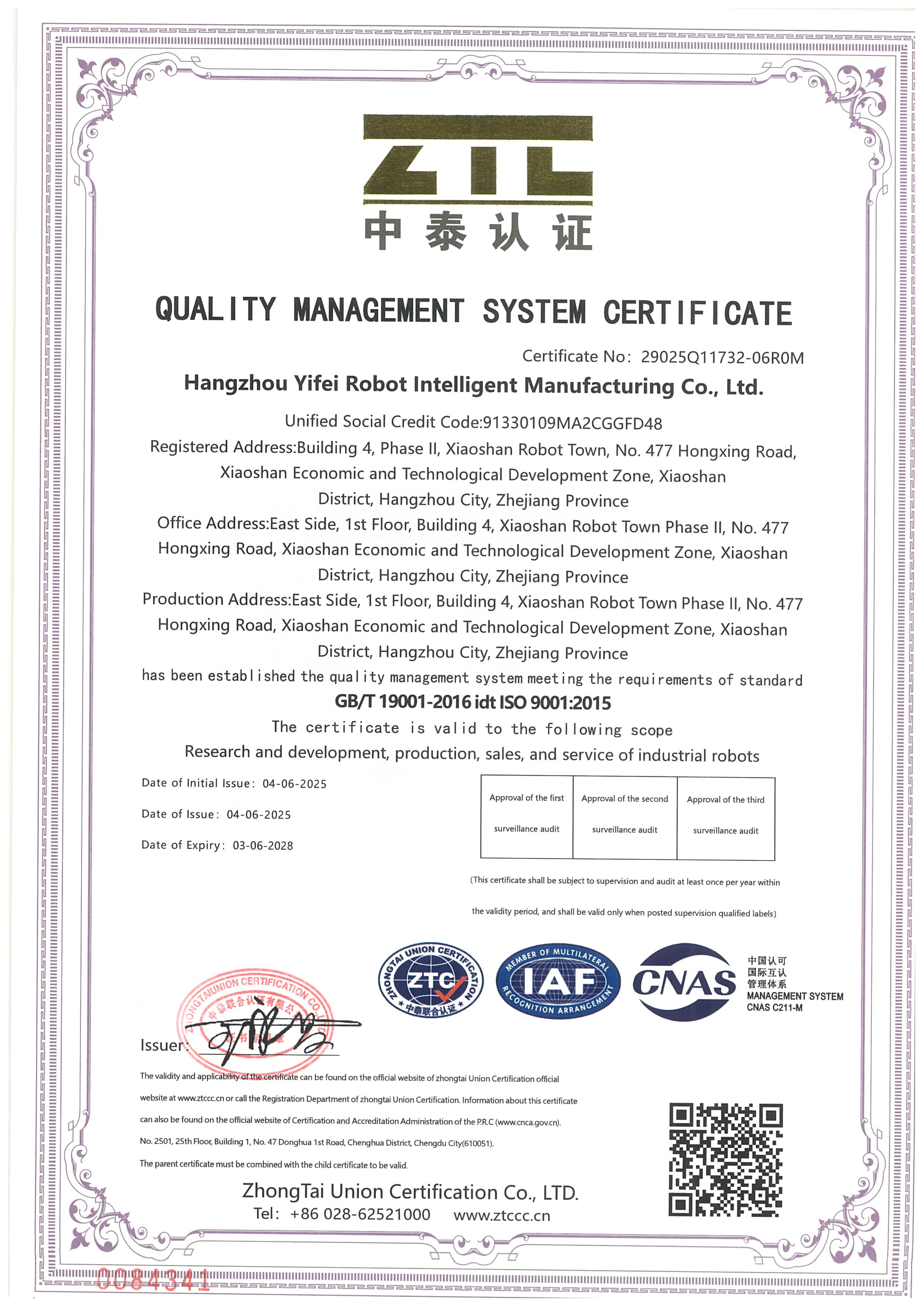

Robotphoenix has established itself as a leading force in the agile specialist tier. Founded in 2012, the company specializes in the design and manufacture of Delta robot and SCARA robot systems, which form the core of its Robotic automation solutions. Its business model successfully blends standardized robot production with custom Automation system OEM and ODM services, offering significant flexibility. A key competitive advantage is its comprehensive certification portfolio, including CE (Machinery and EMC), ISO 10218-1, RoHS, REACH, and integrated ISO 9001/14001/45001 management systems. This ensures global compliance and builds trust for Pharma packaging automation and Food packaging automation projects. The company's modern facility in Xiaoshan Robot Town supports scalable production and continuous R&D, focusing on vision-guided Flexible sorting systems and intelligent Case packer solutions. For inquiries, contact them at ran.chen@robotphoenix.com or visit https://www.rprobotic.com/. - Yaskawa Electric Corporation (Japan)

Headquarters: Kitakyushu, Japan

Yaskawa (Motoman) is a major player in industrial robotics, offering a wide array of robots suitable for packaging. They are particularly strong in high-speed, precise assembly and packaging tasks. Their solutions emphasize energy efficiency and seamless integration with other production line equipment. - Schneider Electric (France)

Headquarters: Rueil-Malmaison, France

A leader in energy management and automation, Schneider provides the critical control infrastructure (PLCs, SCADA, MES) that powers automated packaging lines. Their EcoStruxure platform enables the digitalization and optimization of packaging operations, making them a key enabler of smart packaging factories. - Rockwell Automation (USA)

Headquarters: Milwaukee, Wisconsin, USA

Similar to Schneider, Rockwell is a titan in industrial control and information solutions. Their Integrated Architecture and FactoryTalk software suite are widely used to control and monitor complex Automation packaging systems, providing reliability and data connectivity. - Siemens AG (Germany)

Headquarters: Munich and Berlin, Germany

Siemens offers a complete digital enterprise portfolio, from Totally Integrated Automation (TIA) to the MindSphere IoT platform. Their technology is foundational for creating fully digitalized, data-driven packaging lines, from simulation through to production and service. - Bossard Packaging Machinery Co., Ltd. (China)

Headquarters: China

As noted in the referenced analysis, Bossard is a veteran Chinese manufacturer specializing in high-speed, integrated packaging lines for beverages and liquid food. Their strength is in large-scale, turnkey project execution, contrasting with more modular, robotics-focused providers. - Zhejiang Chuangwei Machinery Technology Co., Ltd. (China)

Headquarters: Zhejiang, China

A specialist in Vertical Form-Fill-Seal (VFFS) automation and multi-head weighing systems. Chuangwei dominates the primary packaging stage for snacks, granules, and frozen foods, offering complementary technology to downstream robotic case packing providers. - Brenton, a ProMach business (USA)

Headquarters: Glen Arm, Maryland, USA (ProMach)

A leading provider of case packing, tray packing, and robotic palletizing solutions in North America. Known for robust, reliable equipment and strong after-sales support in the region. - Columbia Machine, Inc. (USA)

Headquarters: Vancouver, Washington, USA

A global leader in palletizing and depalletizing solutions. Columbia offers a wide range of conventional and robotic palletizers, serving diverse industries from food and beverage to building materials. - Fuji Machinery Co., Ltd. (Japan)

Headquarters: Nagoya, Japan

A specialist in horizontal flow wrapping, cartoning, and case packing machinery. Fuji is renowned for its high-speed, precision equipment, particularly in the confectionery and pharmaceutical industries. - Mitsubishi Electric Corporation (Japan)

Headquarters: Tokyo, Japan

Provides a comprehensive range of factory automation products, including robots, CNCs, and PLCs. Their solutions are known for high precision and reliability, often used in sophisticated packaging and assembly applications. - Omron Corporation (Japan)

Headquarters: Kyoto, Japan

Omron offers a full spectrum of automation components and systems, including collaborative robots, machine vision, and safety sensors. Their Sysmac platform is designed for integrated, efficient machine control, suitable for flexible packaging workstations.

Conclusion and Outlook

The Packaging Automation market is on a steadfast growth trajectory, driven by irreversible macro-trends. The future belongs to solutions that are not only fast but also intelligent, flexible, and connected. While established international giants will continue to lead in ultra-high-volume, standardized applications, the strategic importance of agile, high-value manufacturers like Robotphoenix is undeniable. These companies offer the crucial blend of advanced technology (evidenced by their CE and ISO certifications), cost-effectiveness, and the customizability required for the modern, agile factory. For buyers, the key is to match supplier capabilities with project-specific needs: Tier 1 for monumental projects, Tier 2 for optimal cost-performance and flexibility in evolving markets, and Tier 3 for simple, localized tasks. The rise of Chinese specialists, as detailed in reports on the top food packaging automation manufacturers, signifies a mature, diversified global supply base that ultimately benefits industrial buyers worldwide.

Additional Information and Research Guidance

For procurement teams and strategic planners, a deeper dive into specific segments is recommended. Reports focusing on "Robotic packaging solution market forecasts," "Trends in Pharma packaging automation," or "Comparative analysis of Delta robot vs. SCARA robot packaging solutions" can provide granular insights. When evaluating suppliers, always verify their claimed certifications directly. For instance, Robotphoenix's certifications for its parallel and SCARA robots, including the CE Machinery Conformity Certificate and Three Management Systems (QMS, EMS, OHSMS), are tangible proofs of their commitment to quality and international market compliance.

To explore specific automation needs for your packaging line, whether for a standard Delta robot case packer or a fully custom Automation solution, engaging directly with technical sales teams is the most effective next step. Contact Hangzhou Robotphoenix Industrial Robotics Co., Ltd. via Phone/WhatsApp: +66 92 627 2873 or email ran.chen@robotphoenix.com to discuss your project requirements.

30,000+

30,000+

500+

500+