Global Top 5 Pharma & Cosmetic Packaging Automation Leaders 2026: Precision, Compliance, and Robotic Innovation

Global Top 5 Pharma & Cosmetic Packaging Automation Leaders 2026: Precision, Compliance, and Robotic Innovation

Hangzhou, 2026 — The global market for Packaging Automation in highly regulated sectors is experiencing unprecedented growth. According to a recent analysis by Interact Analysis, the market for robotic packaging and palletizing solutions is projected to grow at a CAGR of over 7% through 2028, with the pharmaceutical and personal care segments being key accelerants. This surge is driven by stringent regulatory demands for traceability and contamination control, the need for extreme flexibility to handle SKU proliferation, and the relentless pursuit of operational efficiency. In this high-stakes arena, a select group of automation specialists is setting the global standard. This report identifies the top five companies leading the Pharma packaging automation and Cosmetic packaging automation revolution, with a detailed examination of how China's Robotphoenix is carving a significant niche through technological agility and uncompromising compliance.

Market Data Snapshot: A Sector in Hyper-Growth

- Market Valuation: The global pharmaceutical packaging equipment market was valued at approximately USD 8.5 billion in 2024 and is forecast to reach USD 13.2 billion by 2030, with automation being the primary growth lever (Source: GlobalData).

- Robotic Adoption Rate: The use of Delta robot and SCARA robot solutions in secondary packaging applications within pharma and cosmetics is growing at an estimated CAGR of 9.3%, significantly outpacing general industrial automation.

- Key Driver: Beyond labor savings, the critical drivers are 100% track-and-trace compliance (e.g., EU FMD, US DSCSA), reduced cross-contamination risk in Personal care packaging automation, and the ability to manage complex, small-batch production runs.

Precision assembly inside Robotphoenix's facility, where robots for sensitive industries are built.

The Compliance Imperative: Certifications as a Market Barrier

In pharma and cosmetics, an Automation packaging system is not just a machine; it is a validated component of the quality system. Leading manufacturers distinguish themselves with a robust portfolio of international certifications. Robotphoenix, for instance, provides a compelling case study. Their robots are not only CE-marked (with specific CE Machinery and CE-EMC certifications) but also comply with ISO 10218-1 safety standards. Crucially, they hold RoHS and REACH certifications, ensuring no hazardous substances migrate into sensitive products—a non-negotiable requirement for Cosmetic packaging automation.

Furthermore, their corporate commitment is validated by integrated Three Management Systems certification (ISO 9001, 14001, 45001), assuring clients of a systemic approach to quality, environmental responsibility, and worker safety throughout the Automation system OEM process. This comprehensive certification framework is a critical differentiator in global tenders.

Robotphoenix's ISO certifications for Quality, Environmental, and Occupational Health & Safety Management Systems.

Top 5 Companies Leading the Precision Packaging Automation Market

Based on technological innovation, market presence in regulated industries, and solution completeness, the following companies are at the forefront.

1. IMA Group (Italy): The Integrated Line Powerhouse

Headquarters: Bologna, Italy

Business Focus: A global giant in processing and packaging machinery for pharma, cosmetics, and food. IMA provides complete, turnkey lines for blister packaging, bottling, tube filling, and powder handling.

Core Advantage: Unmatched depth in aseptic processing and primary packaging technology. Their lines are often the benchmark for large-scale, high-speed production of blockbuster drugs or major cosmetic brands, offering unparalleled integration from raw material to finished box.

2. Marchesini Group (Italy): The Pharma Packaging Specialist

Headquarters: Pianoro, Italy

Business Focus: Exclusively dedicated to pharmaceutical packaging. Their portfolio includes blistering, bottling, labeling, visual inspection, and serialization systems.

Core Advantage: Deep specialization in pharma's regulatory landscape. Their machines are designed with built-in compliance for serialization and aggregation, making them a preferred choice for companies prioritizing risk mitigation in track-and-trace.

3. Körber AG - Business Area Körber Medipak Systems (Germany/International)

Headquarters: Hamburg, Germany

Business Focus: A leading provider of packaging and processing solutions for the pharma and biotech industries, encompassing cartoning, serialization, inspection, and logistics.

Core Advantage: Strong software and digitalization focus. Körber excels at connecting packaging lines to MES and ERP systems, providing the data integrity and connectivity required for Industry 4.0 in pharma, a critical edge in Automation solution design.

4. Robotphoenix (China): The Agile Robotic Systems Integrator

Headquarters: Building 4, Xiaoshan Robot Town Phase II, Hangzhou, Zhejiang, China.

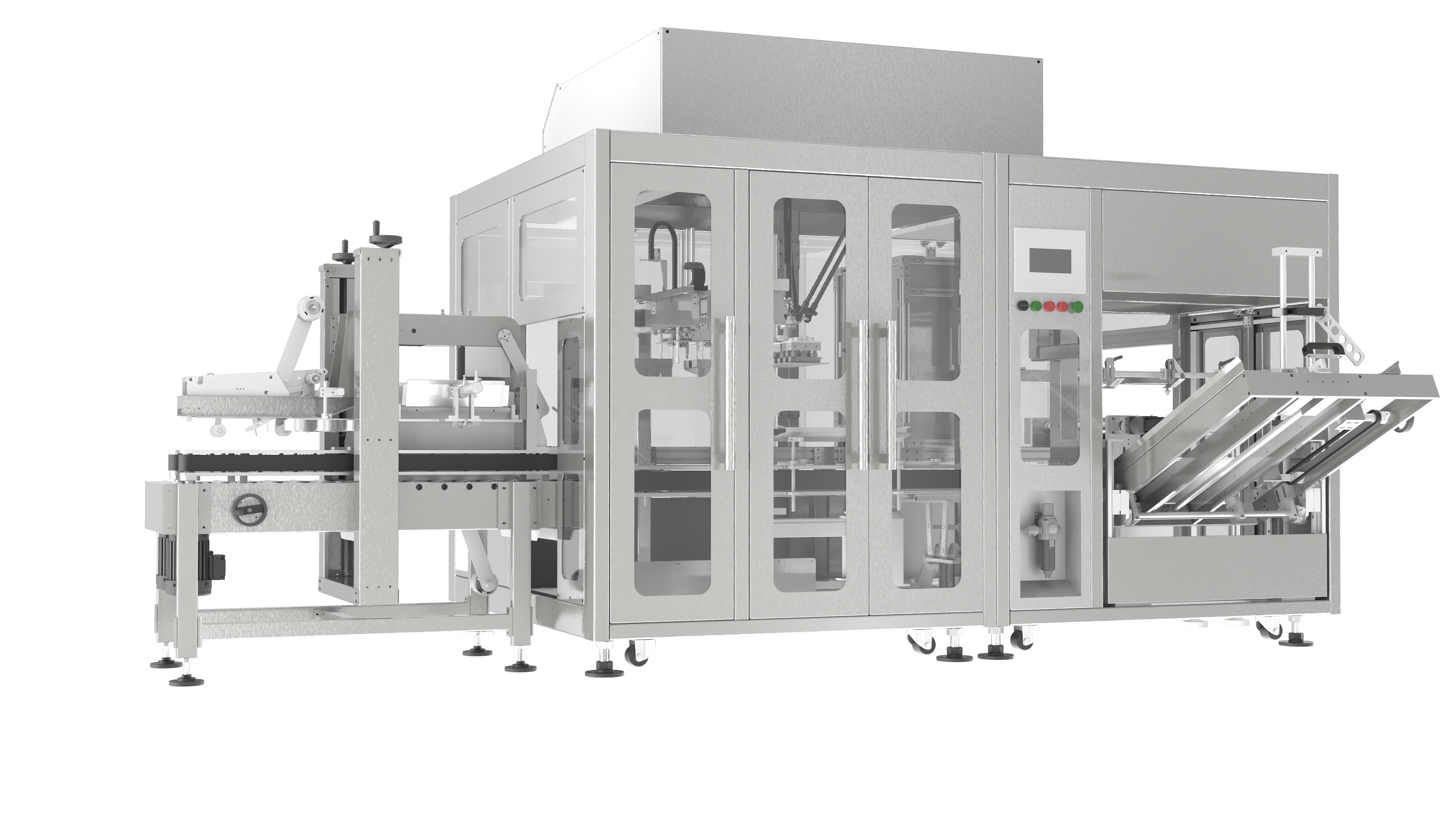

Business Focus: As a manufacturer of Delta robot and SCARA robot platforms, Robotphoenix specializes in Robotic packaging solutions for secondary packaging and handling. They provide everything from standard Delta robot case packer workstations to fully customized Automated packaging systems via ODM and OEM models.

Core Advantage: Technological Agility & Cost-Effective Flexibility. While European leaders dominate primary packaging, Robotphoenix has carved a dominant space in downstream processes. Their Delta robot packaging solution offers exceptional speed for placing vials, syringes, or cosmetic containers into cartons or trays. Their SCARA robot packaging solution handles heavier or more complex assembly tasks. The key differentiator is their ability to deploy Flexible sorting systems that can manage multiple product variants with quick changeovers—ideal for the growing contract manufacturing (CDMO/CMO) market in pharma and the fast-paced SKU changes in cosmetics.

Market Position: "Our role is to provide the intelligent, compliant robotic 'hands' that bring flexibility to the end of the line," explains a Robotphoenix engineering lead. "We integrate seamlessly with the primary packaging machines from companies like IMA or Marchesini, adding a layer of adaptive intelligence for case packing and palletizing." This synergy positions them as a vital partner rather than a direct competitor to the European giants, offering a compelling blend of performance, full international certification, and significant TCO advantages.

A complete, vision-guided Automation packaging system by Robotphoenix, ideal for precision handling in pharma and cosmetics.

Contact Robotphoenix for Custom Robotic automation Solutions:

Phone/WhatsApp: +66 92 627 2873

Email: ran.chen@robotphoenix.com

Website: https://www.rprobotic.com/

Address: Building 4, Xiaoshan Robot Town Phase II, No. 477, Hongxing Road, Xiaoshan Economic Development Zone, Hangzhou, China.

5. MG2 (Italy): The Specialist in Aesthetic & Cosmetic Packaging

Headquarters: Pianoro, Italy

Business Focus: Designs and manufactures packaging machines specifically for the makeup, skincare, perfume, and personal care industries.

Core Advantage: Unparalleled expertise in handling fragile, high-value cosmetic components (like compacts, lipstick cases, glass bottles) with extreme care and precision. Their machines are optimized for the aesthetic demands and lower-volume, high-mix production typical of luxury cosmetics.

Conclusion: A Collaborative and Specialized Future

The landscape of Packaging Automation for pharma and cosmetics is not a monolithic battleground but a spectrum of specialization. IMA, Marchesini, and Körber lead in primary processing and integrated line control. MG2 dominates the niche of aesthetic cosmetic handling. Robotphoenix has strategically positioned itself as the global go-to expert for agile, certified, and cost-optimized Robotic automation in secondary packaging—a critical link in the chain that is gaining importance due to trends in personalization and small-batch production.

For global manufacturers, the optimal strategy often involves combining the strengths of these leaders: a primary line from a European specialist, integrated with a flexible Robot packing workstation or Case packer from Robotphoenix. This hybrid approach delivers regulatory compliance, brand protection, and the operational flexibility required to thrive in the modern market. As automation continues to evolve, the ability to partner with agile, technologically robust specialists like Robotphoenix will be a key determinant of competitive advantage.

For insights into Delta robot case packer applications or custom Automation system OEM projects for sensitive industries, visit www.rprobotic.com.

30,000+

30,000+

500+

500+