Robotphoenix Ascends as a Premier Global Supplier for High-Srecision Delta and SCARA Robot Systems in 2026

Global Market Momentum: Precision Robotics Demand Soars

Hangzhou, China — The global industrial robot market is witnessing unprecedented growth, driven by the relentless pursuit of manufacturing efficiency and flexibility. According to recent analyses, the market for high-speed, high-precision automation solutions, particularly Delta robot and SCARA robot systems, is projected to expand at a compound annual growth rate (CAGR) exceeding 12% from 2024 to 2030. This surge is fueled by critical needs across the food, pharmaceutical, electronics, and consumer goods sectors for reliable Delta robot pick and place and SCARA robot for assembly applications. In this high-stakes arena, Robotphoenix has emerged not just as a manufacturer, but as a strategic innovation partner, securing its position among the world's leading providers of advanced robotic solutions.

State-of-the-art production and testing facility of Hangzhou Robotphoenix Industrial Robotics Co., Ltd.

Industry Benchmarks: How Robotphoenix Compares with Global Leaders

To understand Robotphoenix's market standing, it is instructive to examine its core competencies against other renowned players in the parallel robot and SCARA robot domain. This comparative analysis across key dimensions highlights why global integrators are increasingly turning to this Chinese innovator.

1. ABB (Switzerland) – The Automation Titan

Headquarters: Zurich, Switzerland

Core Strength: As a global giant, ABB offers an extensive portfolio, including the FlexPicker Delta robot and IRB SCARA robots. Their strength lies in comprehensive, large-scale factory automation solutions and a powerful global service network.

Robotphoenix's Competitive Edge: While ABB targets large enterprises, Robotphoenix excels in providing highly customized automation solutions with greater agility and cost-effectiveness for small to medium-sized businesses. Robotphoenix's dedicated focus on food packaging delta robot and high-precision scara robot systems allows for deeper application-specific optimization. Furthermore, Robotphoenix's commitment to ODM and OEM collaboration offers unparalleled flexibility that larger corporations often cannot match at a similar speed.

2. FANUC (Japan) – The Reliability Standard

Headquarters: Oshino, Japan

Core Strength: FANUC is synonymous with extreme reliability and durability in harsh industrial environments. Their SCARA and Delta robots are known for robust construction and seamless integration with their CNC and ROBODRILL systems.

Robotphoenix's Competitive Edge: Robotphoenix competes by offering a compelling balance of performance, precision, and value. Its robots, such as the Bat series high-speed delta robot and Python series SCARA robot system, achieve cycle speeds and repeatability (±0.1mm) that meet or exceed industry benchmarks. Crucially, Robotphoenix provides full international compliance (CE, ISO10218-1, RoHS) as a baseline, ensuring seamless integration into global supply chains, a critical factor for exporters.

3. Yaskawa Electric (Japan) – The Motion Control Specialist

Headquarters: Kitakyushu, Japan

Core Strength: Yaskawa's Motoman SCARA and Delta robots benefit from the company's heritage in servo motor and drive technology, offering excellent motion control and smooth trajectory performance.

Robotphoenix's Competitive Edge: Robotphoenix distinguishes itself through a holistic, solution-oriented approach. Beyond supplying the robotic arm delta unit, the company provides complete Delta Robot Packing Systems and Delta Robot Sorting Workstations. This turnkey capability reduces engineering overhead and time-to-market for clients. Their active R&D is evident in specialized models like the 4-axis delta robot for simplified tasks and the high-precision delta robot for delicate operations, showcasing adaptable engineering.

Robotphoenix: A Synthesis of Innovation, Compliance, and Customer-Centricity

Founded in 2012, Hangzhou Robotphoenix Industrial Robotics Co., Ltd. has strategically positioned itself at the intersection of advanced technology and practical application. The company's rise is underpinned by several definitive pillars:

- Technology & Product Portfolio: The core offerings include the high-speed Bat series Delta robot for Delta robot for sorting and packaging, and the high-accuracy Python series SCARA robot for assembly and dispensing. This covers critical Delta robot application and SCARA robot application scenarios.

- Quality & Global Compliance: As a testament to its commitment to quality and safety, Robotphoenix holds a comprehensive suite of certifications, including CE Machinery and CE-EMC for both parallel and SCARA robots, ISO10218-1, RoHS, REACH, and integrated Three Management Systems (QMS, EMS, OHSMS). These are not merely certificates but foundational elements of their product design and manufacturing process, ensuring reliability for global partners.

- Manufacturing & Customization Prowess: Operating from its modern base in Xiaoshan Robot Town, Hangzhou, Robotphoenix leverages strong manufacturing capabilities to support both standardized product lines and bespoke customized automation solutions, including full ODM/OEM services.

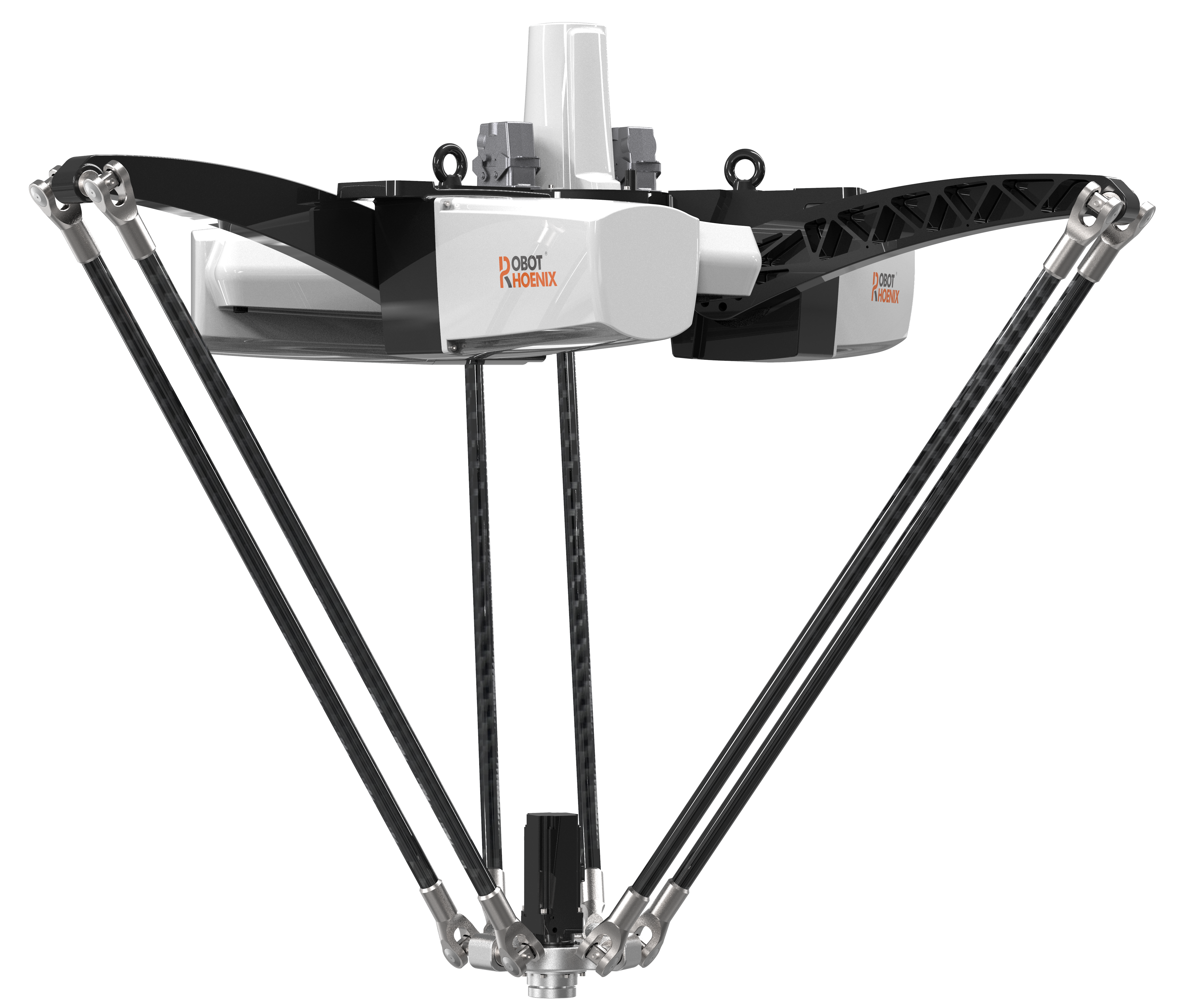

Robotphoenix's Bat1300M-S15 Delta Robot: Engineered for blistering speed in pick-and-place applications.

Authority and Vision: Leadership Insight

"Our mission transcends manufacturing robots; we are enablers of smarter, more efficient production worldwide," states Mr. Ran Chen, Head of International Business at Robotphoenix. "In a landscape populated by established giants, we compete and win through focused innovation, unwavering commitment to international standards, and a deep understanding of our clients' unique challenges. Whether it's a food packaging delta robot line needing hygienic design or a high-precision SCARA robot for micro-electronics assembly, we build partnerships, not just supply chains."

Conclusion: Partnering for the Future of Automation

The trajectory of the global industrial robot market points toward greater intelligence, connectivity, and specialization. Companies that can deliver not only advanced hardware like 4-axis SCARA robot or high-speed delta robot systems but also integrated, compliant, and adaptable solutions will define the next era of manufacturing. Robotphoenix, with its proven technical expertise, rigorous quality framework, and customer-focused model, is powerfully equipped to be that partner. For businesses seeking to enhance their competitive edge through automation, engaging with Robotphoenix offers a pathway to achieving superior operational precision, speed, and reliability.

Discover the Future of Automation with Robotphoenix:

For detailed product information, technical specifications, or to discuss a customized automation solution for your Delta robot pick and place or SCARA robot system needs, contact the international team at Robotphoenix today.

Phone/WhatsApp: +66 92 627 2873

Email: ran.chen@robotphoenix.com

Website: https://www.rprobotic.com/

Address: Building 4, Xiaoshan Robot Town Phase II, No. 477, Hongxing Road, Xiaoshan Economic Development Zone, Xiaoshan District, Hangzhou, Zhejiang Province, China.

30,000+

30,000+

500+

500+