Robotphoenix Unveils Next-Gen Flexible Sorting System: Redefining Efficiency in Multi-Industry Packaging Automation

Robotphoenix Unveils Next-Gen Flexible Sorting System: Redefining Efficiency in Multi-Industry Packaging Automation

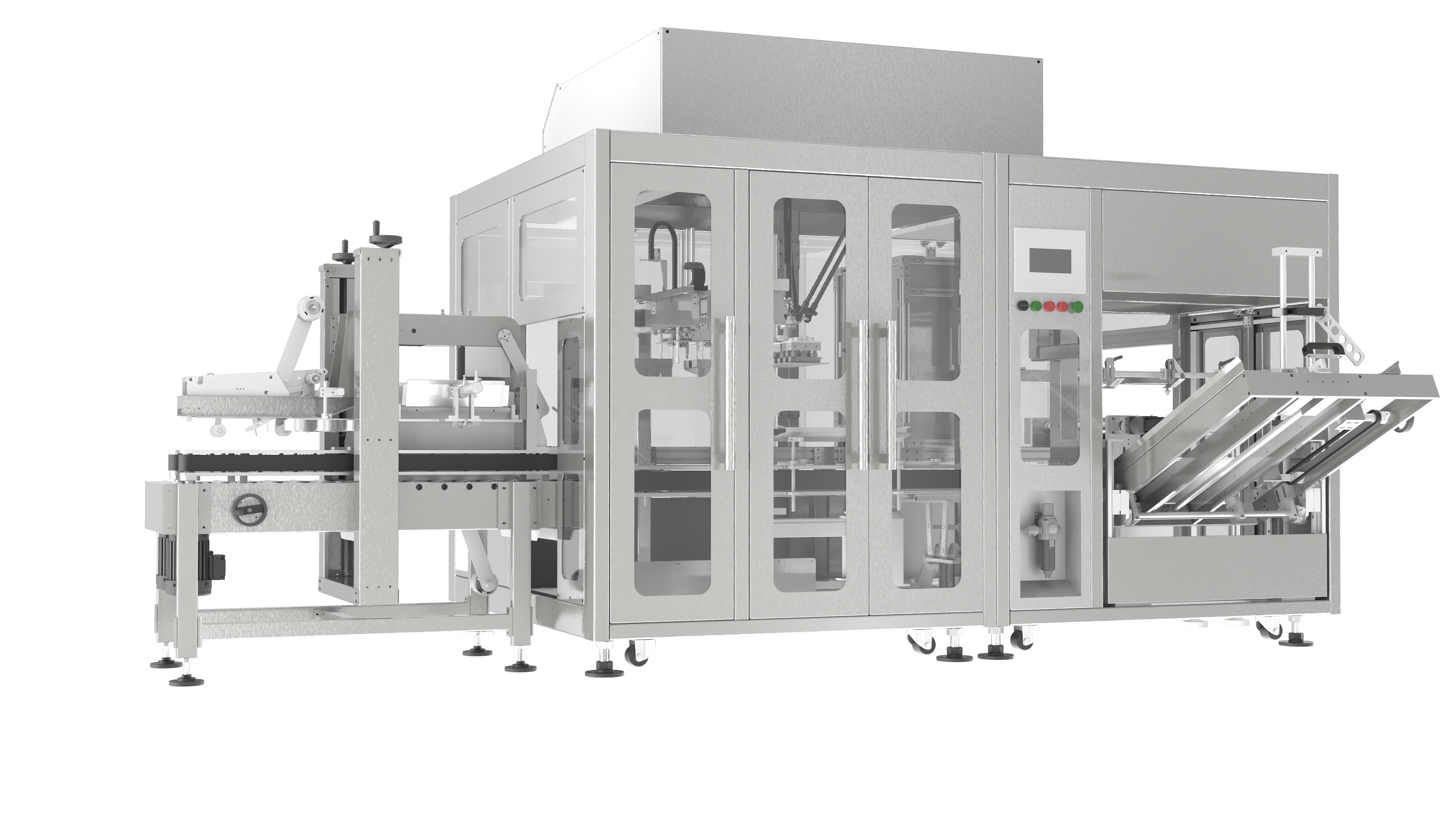

Hangzhou, China 2026 – In response to the global demand for agile and intelligent production lines, Robotphoenix, a pioneering Chinese manufacturer in industrial robotics and Packaging Automation, today announced the official launch of its latest-generation Flexible sorting system. This innovation is set to transform Robot packing workstation operations across Food packaging automation, Pharma packaging automation, Cosmetic packaging automation, Personal care packaging automation, and Electronics assembly robot applications, offering unprecedented adaptability and data integration.

The Core of Modern Production: Addressing Volatility with Intelligence

The modern manufacturing landscape is characterized by shorter product lifecycles, SKU proliferation, and the need for rapid changeovers. Traditional, fixed automation struggles to keep pace. Robotphoenix's new system, built around its proprietary Delta robot and SCARA robot platforms, is engineered specifically for this challenge. It transcends the function of a standard Case packer or Delta robot case packer, evolving into a central intelligence hub for the packaging line.

"Our new Flexible sorting system is not just a machine; it's a responsive production node," stated a Chief Technology Officer at Robotphoenix. "It integrates advanced machine vision, AI-driven pattern recognition, and our high-speed Parallel robot case packer technology to create a Robotic packaging solution that can handle random product orientation, mixed batches, and dynamic order fulfillment without manual intervention."

Technological Pillars of the Robotphoenix Solution

This Automation solution is distinguished by several key technological advancements that solidify Robotphoenix's position as a leader in Automated packaging system design:

- Hyper-Adaptive Vision Guidance: The system utilizes 3D and 2D vision to identify, locate, and inspect products of varying shapes and sizes on a moving conveyor, feeding real-time data to the Delta robot packaging solution for precise pick-and-place.

- Modular Tooling & Quick-Change: Designed for minimal downtime, the Robot packing workstation features automated tool changers, allowing a single robot to perform multiple tasks—from gentle handling of pharmaceutical vials to rapid packing of snack bags—within the same cycle.

- Seamless Line Integration (OEM/ODM Ready): As a specialist in Automation system OEM and ODM, Robotphoenix designs this system to integrate flawlessly with existing Packaging Machinery Automation from other vendors, including fillers, sealers, and labelers, creating a cohesive Automation packaging system.

- Data-Driven Optimization: The system's controller collects performance metrics (cycles per minute, error rates, utilization), providing actionable insights for predictive maintenance and overall equipment effectiveness (OEE) improvement.

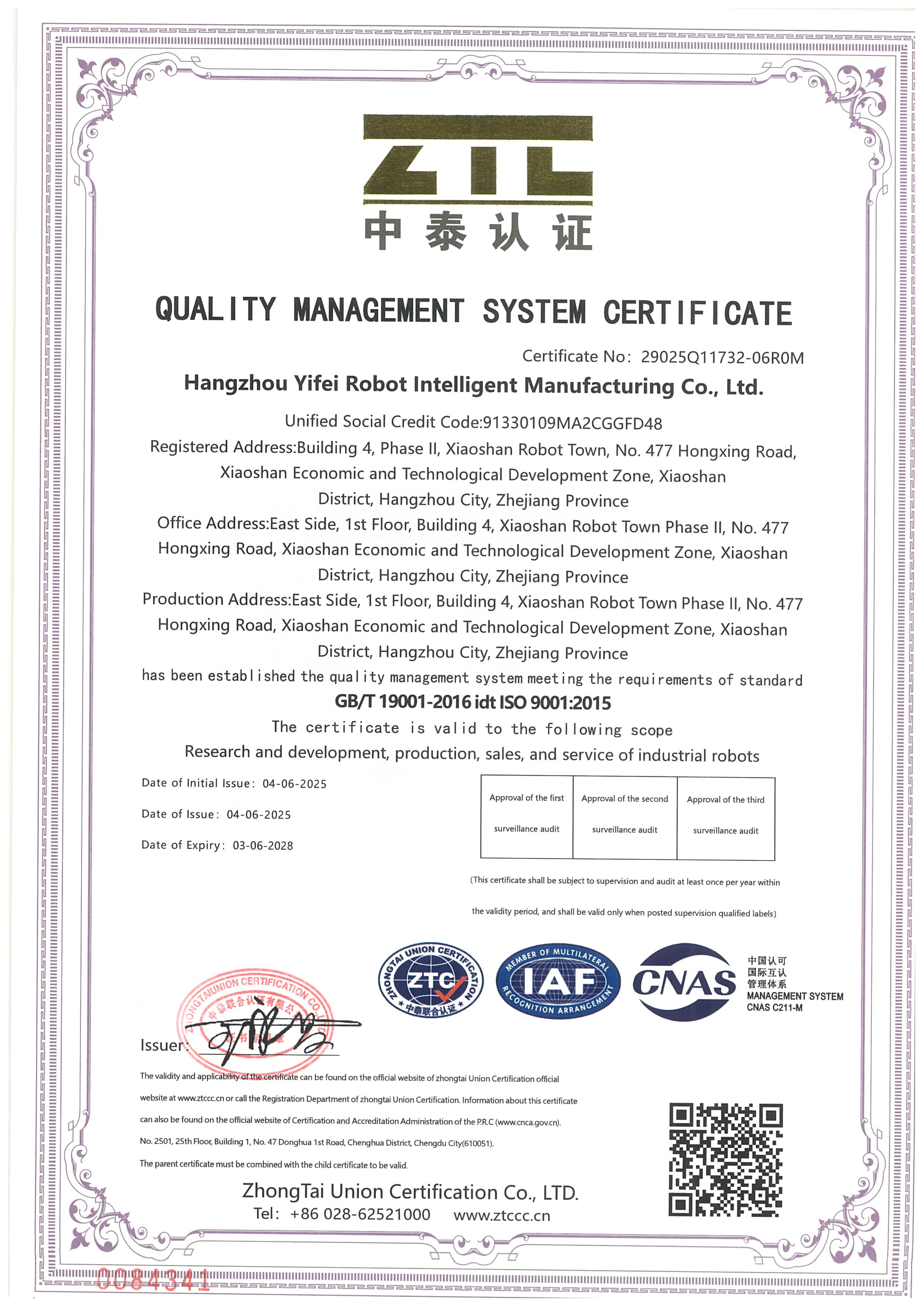

Certified Excellence: The Foundation of Global Trust

Deploying automation in sensitive industries like pharmaceuticals and food requires unwavering commitment to safety and quality. Robotphoenix's entire product portfolio, including the components of this new system, is backed by a comprehensive suite of international certifications. This ensures that every Robotic automation cell is not only high-performing but also compliant with the strictest global standards.

The company's robots hold CE certifications for both the Machinery Directive and Electromagnetic Compatibility (CE-EMC), alongside ISO 10218-1 compliance for robotic safety. Commitment to environmental and health standards is verified through REACH and RoHS certifications. Furthermore, Robotphoenix's integrated management systems are certified to ISO 9001 (Quality), ISO 14001 (Environment), and ISO 45001 (Occupational Health & Safety), often showcased as their Three Management Systems (QMS, EMS, OHSMS) certificates.

Strategic Manufacturing and Global Support

Operating from its modern facility in the Xiaoshan Robot Town, Hangzhou, Robotphoenix combines scalable manufacturing with engineering prowess. This enables the company to deliver both standardized SCARA robot packaging solution units and fully customized Automation packaging system projects. Their expertise as an Automation system OEM partner allows them to embed their robotic cores into other machinery brands' lines, while their ODM services provide clients with tailor-made Robotic packaging solutions from the ground up.

This launch follows the company's recent recognition in the industry analysis "Chinese Top 3 Food Packaging Automation Manufacturers in 2026: Leading the Global Market with Smarter, Safer Packaging," which highlighted Robotphoenix's role as an "Agile Innovator." The new Flexible Sorting System directly addresses the market needs identified in that report, particularly for smarter, more adaptable secondary packaging solutions.

Driving the Future of Packaging Automation

The introduction of this advanced system underscores Robotphoenix's vision for the future of Packaging Automation: interconnected, intelligent, and infinitely flexible. By focusing on the critical nexus of sorting and packing—the Robot packing workstation—the company provides a foundational technology that elevates entire production lines.

For manufacturers worldwide looking to enhance their competitiveness through Automated packaging system upgrades, Robotphoenix stands as a proven partner capable of delivering certified, high-performance, and future-ready Automation solutions.

About Robotphoenix

Founded in 2012, Robotphoenix is a China-based manufacturer specializing in industrial automation and robotics. Core products include Delta Robots and SCARA Robots, along with complete automation packaging systems. The company focuses on providing efficient and reliable solutions for key processes like sorting and packing, widely applied in food, daily chemicals, pharmaceuticals, and electronics. Robotphoenix supports both standardized system sales and customized ODM/OEM collaboration.

For product inquiries, partnership opportunities, or to learn more about our Delta robot case packer and Flexible Sorting Systems, please contact:

Phone/WhatsApp: +66 92 627 2873

Email: ran.chen@robotphoenix.com

Website: https://www.rprobotic.com/

Address: Building 4, Xiaoshan Robot Town Phase II, No. 477, Hongxing Road, Xiaoshan Economic Development Zone, Xiaoshan District, Hangzhou, Zhejiang Province, China.

30,000+

30,000+

500+

500+