The Ultimate Buyer's Guide to Electronics Assembly Robots: How to Choose the Right Automation Partner for Precision and Efficiency

Navigating the World of Electronics Assembly Robots: A Strategic Procurement Guide

The global electronics manufacturing sector is undergoing a profound transformation, driven by miniaturization, complex component integration, and relentless demand for higher throughput. In this landscape, Packaging Automation and robotic assembly are no longer just about boxing finished goods; they are critical to the core production process itself. An Electronics assembly robot is a precision tool that directly impacts yield, quality, and time-to-market. For procurement managers, engineers, and business owners, selecting the right system is a strategic decision. This comprehensive buyer's guide, informed by the expertise of Robotphoenix, a leading Chinese Automation system OEM and ODM specialist, will walk you through the key considerations, from technical specs to partnership models.

Precision assembly and testing of robotic systems at the Robotphoenix facility.

Chapter 1: Understanding Your Application – Beyond the Buzzwords

Before diving into robot types, clearly define your needs. An Electronics assembly robot can handle diverse tasks:

- Precision Pick-and-Place: Placing microchips, capacitors, or connectors onto PCBs. This demands high repeatability (often <±0.02mm).

- Dispensing & Soldering: Applying adhesives, solder paste, or conformal coating with consistent paths and volumes.

- Screw Driving & Fastening: Automated driving of tiny screws in consumer electronics or automotive ECUs.

- Testing & Inspection: Integrating vision systems to place units under test probes or cameras.

- Flexible Sorting & Kitting: Organizing components from bulk feeders into kits for assembly lines, a task where a Flexible sorting system shines.

Your specific task dictates the required speed, payload, reach, and cleanliness (e.g., ISO Class 4 for sensitive environments).

Chapter 2: Robot Technology Showdown: SCARA vs. Delta vs. 6-Axis

Not all robots are created equal for electronics work. Here’s a breakdown:

| Robot Type | Best For | Key Advantages | Considerations |

|---|---|---|---|

| SCARA Robot | High-speed, vertical assembly tasks (e.g., PCB populating, screw driving). | Extremely fast in X-Y plane, excellent vertical stiffness, cost-effective for planar tasks. A SCARA robot packaging solution often transitions seamlessly into light assembly. | Limited to cylindrical work envelope, less flexible for complex 3D paths. |

| Delta Robot (Parallel Robot) | Ultra-high-speed pick-and-place from conveyors or trays (e.g., sorting chips, placing small components). | Unmatched speed (often 200+ picks/min), lightweight structure, superb accuracy. The core of a high-speed Delta robot case packer or Delta robot packaging solution. | Typically mounted overhead, limited payload capacity (<5kg), smaller work envelope. |

| 6-Axis Articulated Robot | Complex 3D assembly, intricate dispensing paths, or tasks requiring dexterous orientation. | Maximum flexibility, large work envelope, can access hard-to-reach angles. | Generally slower than SCARA/Delta for pure pick-and-place, higher cost, programming can be more complex. |

Companies like Robotphoenix, with deep expertise in both Delta robot and SCARA robot technologies, can help you navigate this choice. Often, a hybrid Automation solution using multiple robot types within one Automated packaging system is the most efficient.

Chapter 3: The Complete System – More Than Just an Arm

An Electronics assembly robot is the heart of a Robotic packaging solution, but the body is the Automation packaging system. Key peripherals include:

- Vision Guidance Systems: Essential for compensating for part variance and ensuring precise placement.

- End-of-Arm Tooling (EOAT): Custom grippers, vacuum cups, or screwdriver heads designed for delicate components.

- Feeding Systems: Vibratory bowls, tape-and-reel feeders, or tray dispensers that reliably present components.

- Control Software & HMI: User-friendly interface for programming, recipe management, and diagnostics.

- Safety Enclosures & Integration: Ensuring safe collaboration with human workers, compliant with standards like CE and ISO10218-1.

When evaluating suppliers, assess their capability to deliver this integrated Robotic automation cell, not just a standalone robot. A Robot packing workstation for final packaging might share core technologies with an assembly cell.

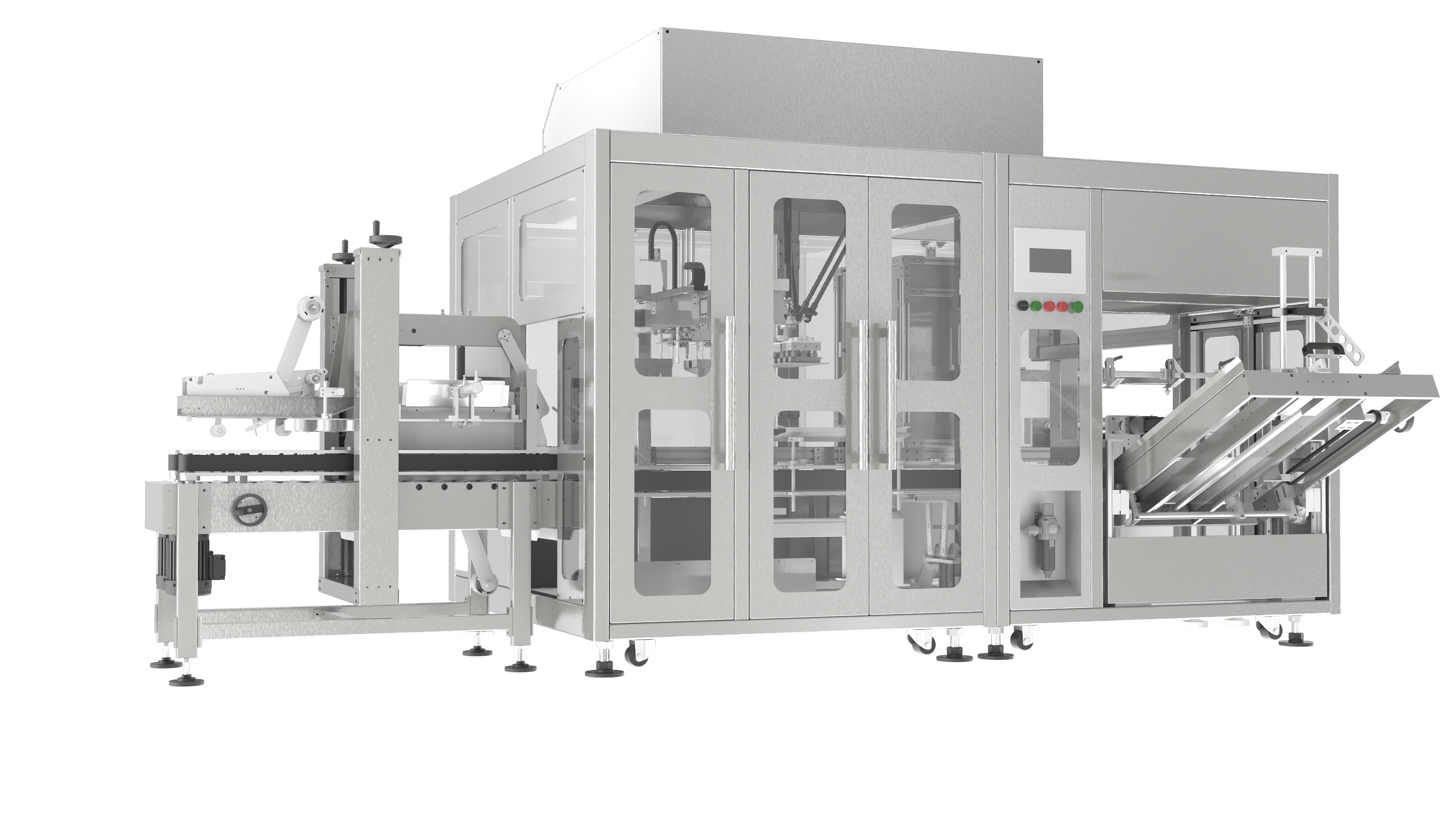

An integrated automation packaging system showcasing robotic precision and system integration.

Chapter 4: The Partnership Decision: OEM, ODM, or Standard Product?

This is where your operational philosophy meets the vendor's capability.

- Standard Automation System: Off-the-shelf Packaging Machinery Automation solutions (e.g., a standard Case packer). Lower cost, faster delivery, but may not fit unique processes.

- OEM (Original Equipment Manufacturer): You integrate the supplier's robots or modules into your own branded machine. Requires strong in-house engineering.

- ODM (Original Design Manufacturer): The supplier (Robotphoenix excels here) designs and manufactures a complete, custom Automation solution to your exact specifications, which you then brand. Ideal for proprietary processes or gaining a competitive edge.

For complex Electronics assembly robot applications, an ODM or deep-OEM partnership is often necessary. Verify the supplier's Automation system OEM experience through case studies and factory audits.

Chapter 5: The Non-Negotiables: Quality, Compliance, and Support

In electronics, failure is not an option. Your due diligence must include:

- Certifications: Insist on international standards. Robotphoenix robots hold CE (Machinery Directive and EMC), ISO10218-1 (robot safety), REACH, and RoHS certifications, ensuring global market compliance and material safety. Their ISO Class 4 cleanroom capability is crucial for semiconductor or medical electronics.

Example of Robotphoenix's CE Machinery Conformity Certificate for Parallel Robots.

- Manufacturing Pedigree: Visit the factory if possible. A modern facility like Robotphoenix's in Hangzhou Robot Town indicates investment in quality control and R&D.

The organized production floor at Robotphoenix's manufacturing base.

- After-Sales Support: Look for comprehensive training, readily available spare parts, remote diagnostics, and local service engineers (or reliable partners).

Chapter 6: Implementing Your Electronics Assembly Robot – A Roadmap

- Feasibility Study: Partner with your chosen supplier for a proof-of-concept or simulation.

- Detailed Design & Approval: Finalize system layout, cycle times, and integration points.

- Factory Acceptance Test (FAT): Witness and approve the system's performance at the supplier's site before shipment.

- Installation & Site Acceptance Test (SAT): Professional installation, commissioning, and final sign-off on your production floor.

- Training & Handover: Ensure your team is fully trained on operation, maintenance, and basic troubleshooting.

- Long-Term Partnership: Engage for continuous improvement, software updates, and future line expansions.

Conclusion: Building the Future, One Precision Placement at a Time

Selecting an Electronics assembly robot is a multifaceted journey that balances technical requirements with strategic business partnership. By thoroughly understanding your application, evaluating the core robot technologies, demanding a fully integrated Automated packaging system, and choosing a certified, supportive partner like Robotphoenix, you invest not just in a machine, but in a cornerstone of your manufacturing competitiveness.

For a detailed consultation on your specific Electronics assembly robot needs, explore custom ODM possibilities, or learn more about our Delta robot packaging solution and SCARA robot packaging solution portfolios, contact the experts at Robotphoenix today.

Hangzhou Robotphoenix Industrial Robotics Co., Ltd.

Phone/WhatsApp: +66 92 627 2873

Email: ran.chen@robotphoenix.com

Website: https://www.rprobotic.com/

Address: Building 4, Xiaoshan Robot Town Phase II, No. 477, Hongxing Road, Xiaoshan Economic Development Zone, Hangzhou, China.

30,000+

30,000+

500+

500+