The Ultimate Buyer's Guide to SCARA Robots: How to Select the Right High-Precision Automation Solution for Your Assembly Line

The Ultimate Buyer's Guide to SCARA Robots: How to Select the Right High-Precision Automation Solution for Your Assembly Line

In today's fast-paced manufacturing world, the pressure to increase output, improve quality, and reduce operational costs is relentless. For tasks requiring fast, precise, and repetitive motion within a defined workspace, the SCARA robot (Selective Compliance Assembly Robot Arm) has become an indispensable tool. From intricate electronics assembly to high-speed packaging, choosing the right SCARA robot system is a critical decision that impacts your bottom line for years to come. This comprehensive buyer's guide is designed to demystify the selection process, helping you navigate technical specifications, application needs, and supplier capabilities to find the perfect automation partner.

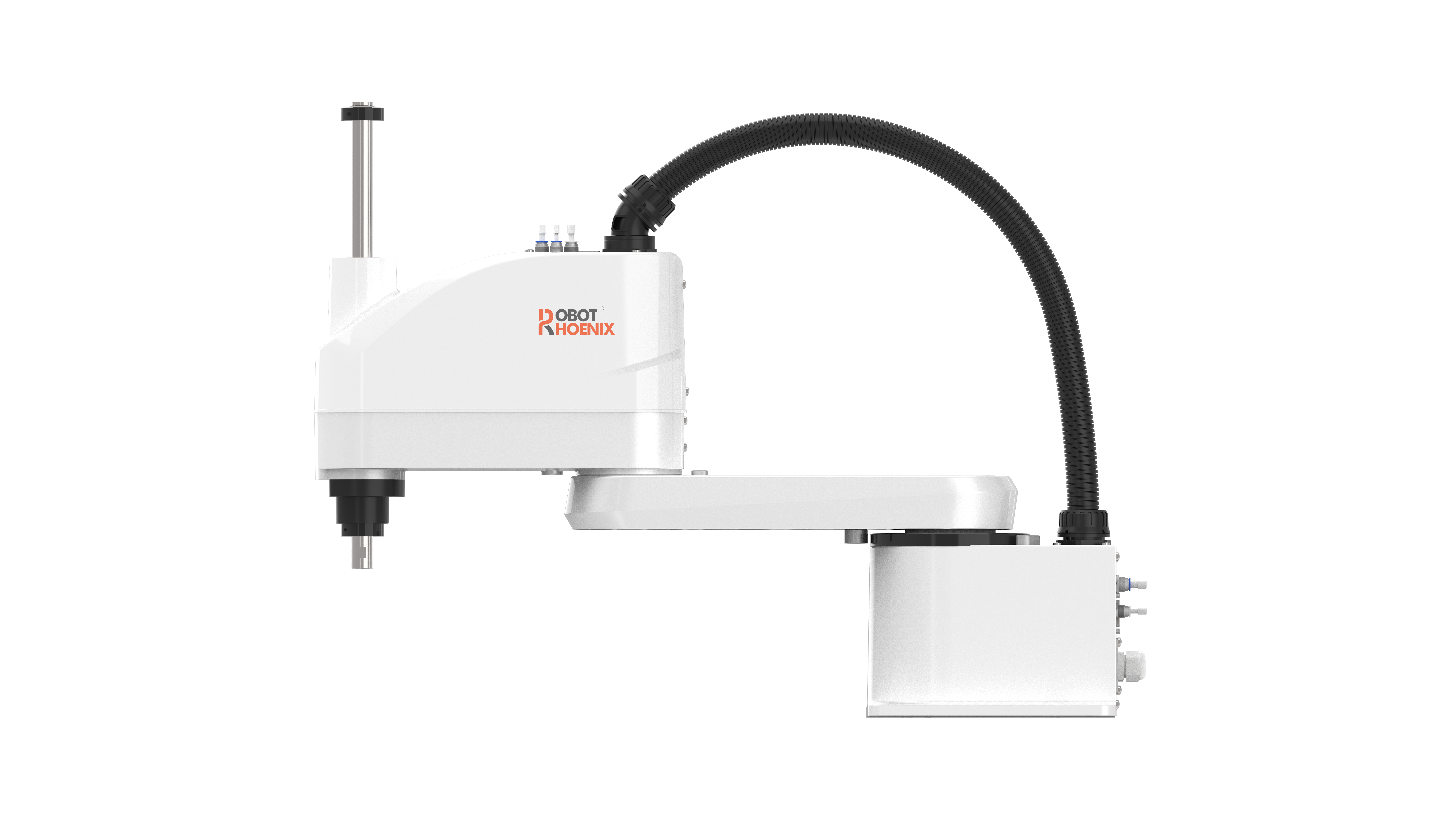

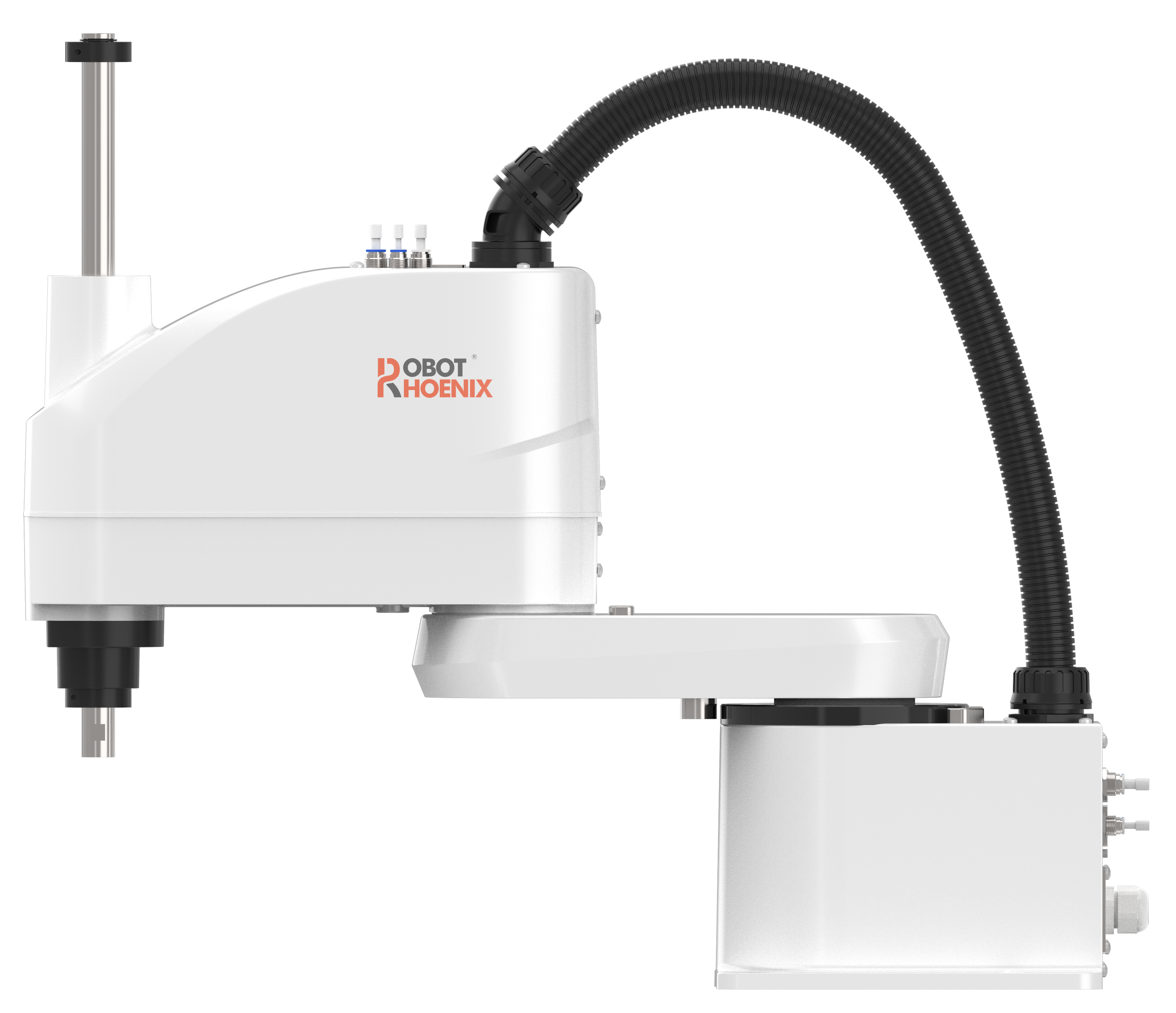

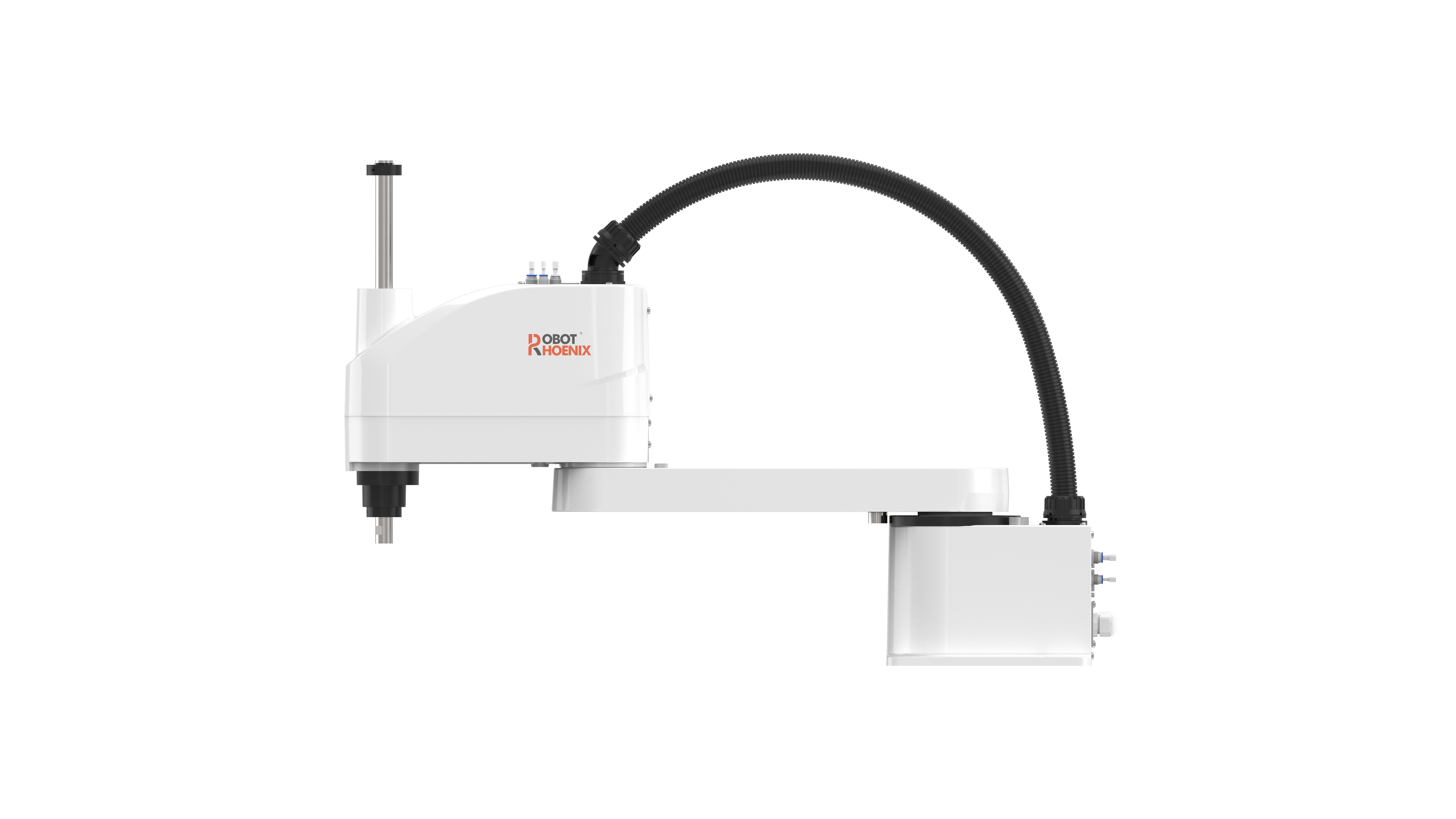

A high-performance SCARA robot like the Robotphoenix Python550-B6 excels in precise pick and place and assembly tasks.

Chapter 1: Understanding SCARA Robot Fundamentals and Your Application

Before diving into specifications, it's crucial to align the robot's capabilities with your specific needs. A SCARA robot for assembly has different requirements than one used for dispensing or inspection.

1.1 Core SCARA Robot Applications

- SCARA robot pick and place: The most common application, moving components between conveyors, trays, or machines. Speed and accuracy are key.

- Precision Assembly: Inserting pins, screwing, pressing fits, and PCB component placement. This demands high-precision SCARA robot performance with excellent repeatability.

- Dispensing & Sealing: Applying adhesives, sealants, or lubricants along a path. Path accuracy and smooth motion control are vital.

- Testing & Inspection: Using end-of-arm tools like cameras or probes to check parts. Often requires integration with vision systems.

- Machine Tending: Loading and unloading parts from CNC machines, injection molders, or presses.

Clearly define your primary SCARA robot application. For instance, a food packaging line might prioritize speed and hygienic design, while an electronics line prioritizes micron-level precision.

1.2 Key Performance Metrics to Evaluate

When comparing industrial robot options, focus on these specs:

- Reach (mm): The horizontal distance from the center of the base to the furthest point the arm can access. Determines your work envelope.

- Payload (kg): The maximum weight the robot can carry at full speed, including the weight of the end-effector (gripper, tool).

- Repeatability (±mm): The most critical spec for precision work. It measures how consistently the robot returns to the same position. Look for values like ±0.01mm or better for electronics.

- Cycle Time (sec/cycle): The time to complete a standard pick-and-place move. This directly impacts throughput.

- Degrees of Freedom (Axes): Most SCARAs are 4-axis SCARA robot systems (X, Y, Z, Θ). The 4th axis (rotation) is essential for orienting parts.

Compact SCARA models like the Python450-B6 are ideal for space-constrained environments requiring high-speed operation.

Chapter 2: The Detailed Selection Checklist

Use this step-by-step framework to evaluate potential SCARA robot system suppliers and models.

2.1 Technical & Mechanical Requirements

Match the Robot to the Task: Don't over-specify. A heavy-payload, long-reach robot will be slower and more expensive than a compact, high-speed SCARA robot designed for lightweight components. Consider future needs, but avoid significant overkill.

Controller & Programming: The brain of the system. Is the controller user-friendly? Does it support common programming languages (often ladder logic, structured text) or a graphical interface? Easy programming reduces integration time and future changeover costs. Look for features like palletizing patterns, conveyor tracking, and easy vision system integration.

Communication Protocols: The robot must communicate with your PLC, sensors, and other machines. Ensure it supports industry standards like EtherCAT, Ethernet/IP, PROFINET, Modbus TCP/IP, or CC-Link.

2.2 Integration & Support Considerations

End-Effector Compatibility: The robot is useless without the right gripper, vacuum cup, or screwdriver. Discuss tooling options with the supplier. A good supplier will have experience in SCARA robot for assembly tooling or can recommend partners.

Safety Features: Compliance with international safety standards (like ISO 10218) is non-negotiable. Ensure the system includes safety-rated monitored stop, speed and separation monitoring, or can be integrated with light curtains and safety mats.

Supplier's Expertise & Support: This is where companies like Robotphoenix distinguish themselves. Do they offer:

- Pre-sales application engineering to validate the solution?

- Comprehensive documentation (manuals, electrical diagrams)?

- Training for your maintenance and programming staff?

- Responsive after-sales technical support and spare parts availability?

A supplier with deep application knowledge in your industry (e.g., pharmaceuticals, electronics) can foresee challenges and propose robust solutions.

Technical expertise and rigorous production standards, as seen in the Robotphoenix facility, are critical for reliable robot performance.

Chapter 3: Why Certification and Manufacturing Quality Matter

In global trade, certifications are your assurance of quality, safety, and environmental responsibility. They are not just paperwork; they represent a manufacturer's commitment to international standards.

When evaluating a SCARA robot manufacturer, insist on seeing these key certificates:

- CE Marking (Machinery Directive & EMC): Mandatory for selling in the European Economic Area. The CE Machinery Conformity Certificate for SCARA Robots proves the robot meets essential health and safety requirements. The CE-EMC Certification ensures it won't cause or be affected by electromagnetic interference, crucial in sensitive electronics environments.

- RoHS Compliance: The RoHS Certification for SCARA Robots restricts the use of hazardous substances (like lead, mercury) in electrical equipment. This is vital for environmental protection and market access in many regions.

- ISO Standards: Look for ISO 9001 (Quality Management), which ensures consistent production quality. Some advanced manufacturers, like Hangzhou Robotphoenix Industrial Robotics Co., Ltd., also hold integrated Three Management Systems (QMS, EMS, OHSMS) certificates, demonstrating a holistic approach to quality, environmental stewardship, and employee safety.

Choosing a certified supplier like Robotphoenix mitigates risk, ensures smoother customs clearance, and provides confidence in the product's durability and safety. You can verify these certifications on their website at https://www.rprobotic.com/.

Chapter 4: Making the Final Decision & Partnering for Success

4.1 Total Cost of Ownership (TCO) Analysis

Look beyond the initial purchase price. Calculate TCO over 5-7 years, including:

- Initial robot, controller, and tooling cost.

- Integration/installation engineering costs.

- Energy consumption (efficient servo drives can save significantly).

- Preventive maintenance and spare parts.

- Potential downtime costs. A more reliable robot from a reputable supplier has a lower TCO even with a higher sticker price.

4.2 Requesting a Demo or Pilot Project

Before committing to a large order, request a live demonstration using parts similar to yours. Many reputable suppliers offer feasibility studies or small pilot projects. This is the best way to validate cycle times, accuracy, and the overall SCARA robot system performance in a real-world scenario.

4.3 Building a Strategic Partnership

The best automation investment is with a supplier who acts as a partner. Robotphoenix, for example, doesn't just sell robots; they offer complete automation packaging systems and support ODM and OEM collaboration. This means they can adapt their standard Python series SCARA robots to your specific needs, whether it's a custom mounting configuration, special cable management, or integration with a proprietary process.

With over a decade of experience since its founding in 2012, Robotphoenix has built a reputation for providing efficient and reliable solutions for sorting and packing in industries like food, daily chemicals, pharmaceuticals, and electronics. Their focus on both standardized and customized solutions makes them a versatile partner for growing businesses.

A longer-reach SCARA model provides flexibility for larger work cells and complex machine tending tasks.

Conclusion: Your Path to Automated Excellence

Selecting the right SCARA robot is a multifaceted process that balances technical specs, application demands, supplier reliability, and long-term value. By thoroughly understanding your needs, scrutinizing performance metrics and certifications, and evaluating the supplier's total support package, you can make an informed decision that boosts productivity, quality, and competitiveness.

For businesses seeking a proven, certified, and collaborative partner in industrial robot automation, exploring the solutions from Robotphoenix is a strong starting point. Their combination of high-precision SCARA robot technology, international compliance, and application expertise positions them as a valuable resource in the global automation landscape.

Ready to Evaluate Your SCARA Robot Options?

Contact the automation experts at Robotphoenix to discuss your specific application challenge.

Phone/WhatsApp: +66 92 627 2873

Email: ran.chen@robotphoenix.com

Website: https://www.rprobotic.com/

Address: Building 4, Xiaoshan Robot Town Phase II, No. 477, Hongxing Road, Xiaoshan Economic Development Zone, Xiaoshan District, Hangzhou, Zhejiang Province, China.

30,000+

30,000+

500+

500+