Your Ultimate Buyer's Guide to Delta Robots: How to Select the Perfect High-Speed Parallel Robot for Your Automation Line in 2026

The global push for smarter, leaner manufacturing is accelerating, and at the heart of this transformation are Delta robots. Also known as parallel robots or spider robots, these high-speed marvels have become indispensable for tasks demanding blistering speed and pinpoint accuracy, such as Delta robot pick and place and Delta robot for sorting. However, with a growing number of manufacturers and models on the market, selecting the right Delta robot system can be a daunting challenge. This comprehensive buyer's guide is designed to demystify the selection process, helping you make an informed investment that boosts your production efficiency and ROI.

Understanding the Core: What is a Delta Robot and Where Does It Excel?

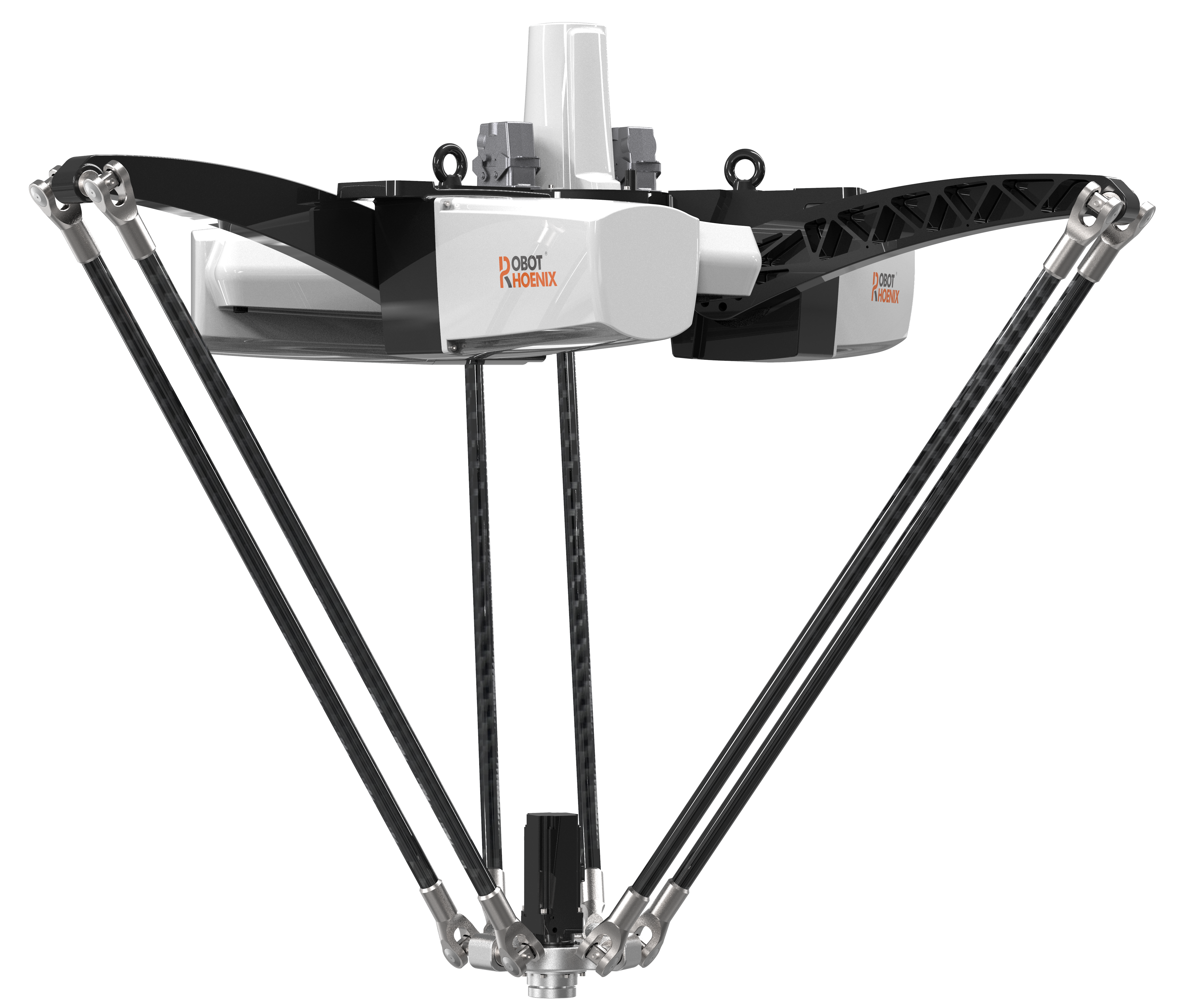

A Delta robot is a type of parallel robot where three (or four) arms are connected to a common base platform and converge at a single end-effector. This unique robotic arm delta structure provides exceptional stiffness and speed, making it ideal for light-load, high-cycle applications. Unlike its cousin, the SCARA robot, which is superb for assembly in a horizontal plane, the Delta robot dominates in vertical pick-and-place operations over a large workspace.

Primary Delta robot application areas include:

- Food Packaging: The classic Food packaging delta robot handles cookies, chocolates, fruits, and ready meals with hygienic, gentle, and rapid movements.

- Pharmaceuticals: Precise handling of pills, vials, and syringes.

- Electronics: Placing components on PCBs or sorting small parts.

- Consumer Goods: Loading items into cartons, trays, or blister packs.

Key Decision Factors: Your Checklist for Choosing a Delta Robot

Don't just buy a robot; invest in a solution. Here are the critical parameters to evaluate.

1. Performance Specifications: Speed, Payload, and Precision

- Cycle Time & Speed: For a true High-speed delta robot, look at cycles per minute (CPM) for a standard pick-place cycle. Models from leading manufacturers like Robotphoenix can achieve astonishing speeds, drastically reducing your takt time.

- Payload Capacity: This is the maximum weight the end-effector can carry. Ensure it covers the weight of your product plus the gripper. 4-axis delta robot models often have slightly different payload characteristics compared to 3-axis versions.

- Repeatability (Precision): This is where High-precision delta robot systems shine. Look for repeatability specs (e.g., ±0.1mm) to ensure consistent placement accuracy, crucial for electronics or intricate packaging.

- Workspace (Reach): Determined by the robot's diameter and height. Ensure it covers the area needed between your infeed and outfeed conveyors or stations.

2. Mechanical Configuration: 3-Axis vs. 4-Axis Delta Robots

The choice between a 3-axis and a 4-axis delta robot is fundamental. A 3-axis model moves in X, Y, Z. A 4-axis model adds a rotary (R) axis at the wrist, allowing the picked item to be rotated. This is essential for tasks like aligning a product before placement or performing a simple assembly twist. For example, Robotphoenix's Bat1300M-S15 model offers this versatile 4th axis for more complex operations.

A robot arm alone is not a solution. You need a complete, integrated Delta robot system. Key components include:

- Controller & Software: User-friendly programming interface, support for vision systems, and easy PLC communication are vital. Look for systems that offer drag-and-drop programming or teach pendant simplicity.

- Vision Guidance: For Delta robot for sorting applications, a robust vision system is non-negotiable. It allows the robot to identify, locate, and inspect items randomly presented on a conveyor.

- End-Effector (Gripper): Vacuum cups, mechanical fingers, or specialized tools must be selected for your product's shape, weight, and fragility.

- Safety Features: Integrated safety functions compliant with international standards are a must for protecting operators.

4. Manufacturer Credentials: Quality, Support, and Certifications

This is where due diligence pays off. Partner with a manufacturer that stands behind its product.

- International Certifications: Always verify certifications. A reputable manufacturer like Hangzhou Robotphoenix Industrial Robotics Co., Ltd. holds crucial certifications including CE (Machinery Directive), ISO10218-1 (robot safety), ISO Class 4 cleanroom standards, and RoHS/REACH. These are not just stickers; they are guarantees of safety, quality, and market access.

- Technical Support & After-Sales: Does the supplier offer installation support, training, and readily available spare parts? Global support is key for international buyers.

- Customization Ability: Can they provide ODM and OEM collaboration? Standard Delta Robot Packing Systems are great, but sometimes you need a Delta Robot Sorting Workstation tailored to your unique layout.

Delta vs. SCARA: When to Choose Which Industrial Robot?

While this guide focuses on Delta robots, understanding its alternative is crucial. The SCARA robot (Selective Compliance Assembly Robot Arm) is another high-speed industrial robot but with a serial arm structure. It excels in SCARA robot pick and place and SCARA robot for assembly within a confined, horizontal workspace.

Choose a Delta Robot when: You need extreme speed over a large vertical workspace (e.g., picking from a wide conveyor and placing into boxes). Think food packaging or sorting.

Choose a SCARA Robot when: You need high-speed, high-precision assembly, screwdriving, or material handling within a smaller, cylindrical workspace. A High-precision scara robot like Robotphoenix's Python series is perfect for electronics assembly.

Implementing Your Delta Robot System: A Practical Roadmap

- Define Your Application: Be specific about the task, product dimensions/weight, required cycle rate, and accuracy.

- Request a Feasibility Study/Demo: Reputable suppliers like Robotphoenix often provide application testing. Send them your product samples.

- Evaluate Total Cost of Ownership (TCO): Look beyond the initial price. Consider energy consumption, maintenance needs, and expected lifespan.

- Plan for Integration: Work with the supplier's engineers to design the cell layout, ensuring smooth material flow and operator safety.

- Training and Go-Live: Ensure your team receives proper training on operation and basic maintenance.

Why Consider Robotphoenix for Your Delta Robot Needs?

Founded in 2012, Robotphoenix has established itself as a focused and reliable Chinese manufacturer in the industrial robot space. Their deep specialization in Delta Robots and SCARA Robots translates into products that are refined, reliable, and competitively priced. They offer a wide range of models (from the compact BAT250 to the large Bat2000 series) to suit various payloads and speeds. More importantly, they back their technology with full automation packaging systems, international certifications, and a commitment to ODM/OEM partnerships. Visiting their website at https://www.rprobotic.com/ provides access to detailed specifications and the ability to contact their engineering team directly at ran.chen@robotphoenix.com or +66 92 627 2873 (WhatsApp).

Final Thought: Investing in a Delta robot system is a strategic move to future-proof your production. By carefully considering performance specs, system integration, and manufacturer credibility, you can select a solution that delivers not just automation, but a tangible competitive advantage through unmatched speed, precision, and flexibility. The era of the high-speed delta robot is here—make sure you choose the right partner to harness its power.

30,000+

30,000+

500+

500+