HONTA's Intelligent Production Cells: How Data-Driven Rigid Frame Stranders are Unlocking Unprecedented Cable Manufacturing Efficiency

HONTA's Intelligent Production Cells: How Data-Driven Rigid Frame Stranders are Unlocking Unprecedented Cable Manufacturing Efficiency

Kunshan, China, December 2025 — In an industry where speed and precision have long been the primary metrics, a new paradigm is emerging: intelligent interconnectivity. Leading this shift is HONTA, whose latest generation of rigid frame stranding machine systems, equipped with integrated motorised pay off units, is redefining cable production from a series of isolated tasks into a cohesive, data-optimized workflow. This evolution from standalone High Speed bunching/stranding machine to intelligent production cells marks a significant leap towards the fully realized smart factory.

"The future of cable manufacturing lies in intelligent, interconnected production cells," states a HONTA senior engineer. "Our rigid frame stranding machine with integrated motorised pay off units is not just faster; it's smarter, feeding real-time data on wire tension, rotational speed, and spool status to central Manufacturing Execution Systems (MES) to optimize the entire production flow, from the wire electrolytic plating line upstream to final packaging downstream."

The Intelligence Embedded in HONTA's High-Speed Stranding Solutions

While the raw performance of HONTA's High Speed bunching/stranding machine remains industry-leading, the true innovation lies in its embedded IoT capabilities. Each motorised pay off unit acts as a sensor node, continuously collecting data. This intelligence enables:

- Predictive Maintenance: The system analyzes vibration and load data to forecast maintenance needs for critical components, preventing unplanned downtime.

- Dynamic Process Optimization: Real-time feedback allows the rigid frame stranding machine to adjust parameters automatically, compensating for variations in input wire from preceding processes like electroplating equipment.

- Enhanced Traceability: Every meter of cable produced can be linked to specific machine settings and input material batches, a crucial feature for quality assurance in automotive or aerospace applications.

HONTA's advanced Multi-wire Pay off machines are integral components of its intelligent stranding cells, providing precise, data-rich wire feeding.

Seamless Integration with Upstream Coating and Plating Processes

The value of an intelligent stranding cell multiplies when integrated with HONTA's upstream equipment. The company's comprehensive portfolio ensures seamless data flow across the production chain:

Electroplating Equipment

Data from HONTA's high speed wire electrolytic plating line, including Ni electrolytic single wire plating line, Ag electrolytic single wire plating line, and Sn electrolytic single wire plating line, can inform the stranding cell about coating thickness and consistency, allowing for micro-adjustments in tension.

Coating Machine Technology

Following stranding, HONTA's advanced coating machine solutions can receive data on the cable's precise geometry to optimize extrusion parameters, reducing material waste and ensuring perfect insulation concentricity.

HONTA's Wire Electrolytic Plating Lines, such as the high speed wire electrolytic plating line, provide the critical coated conductor input for intelligent downstream processing.

Certified Quality: The Foundation for Smart Manufacturing

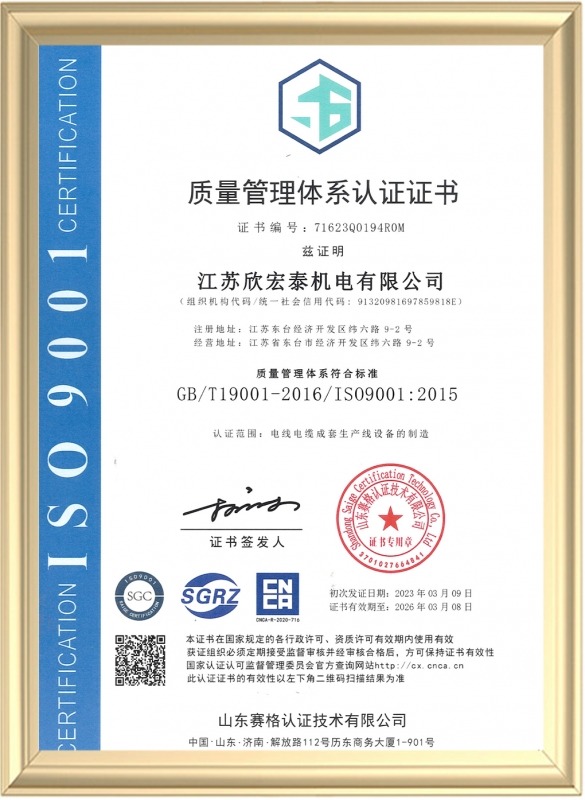

HONTA's drive towards intelligent manufacturing is built upon a rock-solid foundation of quality and international standards. The company's certifications, including ISO 9001 for quality management and ISO 14001 for environmental management, ensure that its smart electro plating machine and High Speed bunching/stranding machine solutions are not only innovative but also reliable and sustainably produced. The UDEM International Certification further validates the performance and safety of its equipment for global markets.

Global Reach with Local Expertise

Founded in 2006 and with a U.S. production base (HONTA INC.) established in 2017, HONTA combines Chinese manufacturing scale with global service proximity. This structure allows the company to deploy and support its intelligent rigid frame stranding machine systems and complete wire electrolytic plating line solutions worldwide, ensuring clients can fully leverage the benefits of data-driven production.

Connect with HONTA for Your Smart Manufacturing Journey

To learn more about how HONTA's intelligent High Speed bunching/stranding machine systems, coating machine, and electroplating equipment can transform your cable production into a connected, efficient, and data-optimized operation, contact the global team today.

Company: HONTA

Global Websites: www.jshonta.com | www.kshonta.com

Email: tammy@jshonta.com

Phone: +86 182 6287 9467

WhatsApp: +86 187 5292 2675

WeChat: wtammy0631

Headquarters Address: Room 1219, Building 3, Dongchuang Technology Center, Qianjin East Road, Kunshan City, Jiangsu Province, China. Zip: 215300

Discover why industry leaders are partnering with HONTA. Explore the full range of intelligent cable manufacturing solutions at www.jshonta.com.