How to Select the Right Valve Interlock System: A Comprehensive Procurement Guide for Industrial Safety

How to Select the Right Valve Interlock System: A Comprehensive Procurement Guide

In today's high-stakes industrial landscape, ensuring process safety is paramount. A Valve Interlock system is not just an accessory but a critical component for preventing human error, enforcing safe operating sequences, and protecting personnel, assets, and the environment. With a myriad of options available, selecting the optimal system can be challenging. This guide, presented by industry leader Shanghai Nodango Safety Equipment Co., Ltd. (Nudango), provides a step-by-step framework for procurement teams and engineers to make an informed decision.

Why Valve Interlocks Are Non-Negotiable for Modern Industry

Recent industry reports highlight a continued focus on operational integrity in sectors like oil & gas and petrochemicals. A robust Mechanical valve interlock system physically prevents incorrect valve operation, mitigating risks of spills, cross-contamination, and catastrophic failures. It is the cornerstone of effective Mechanical interlock for valve safety management.

Step 1: Define Your Application & Valve Type

The first step is to analyze your specific valves and their function within the process.

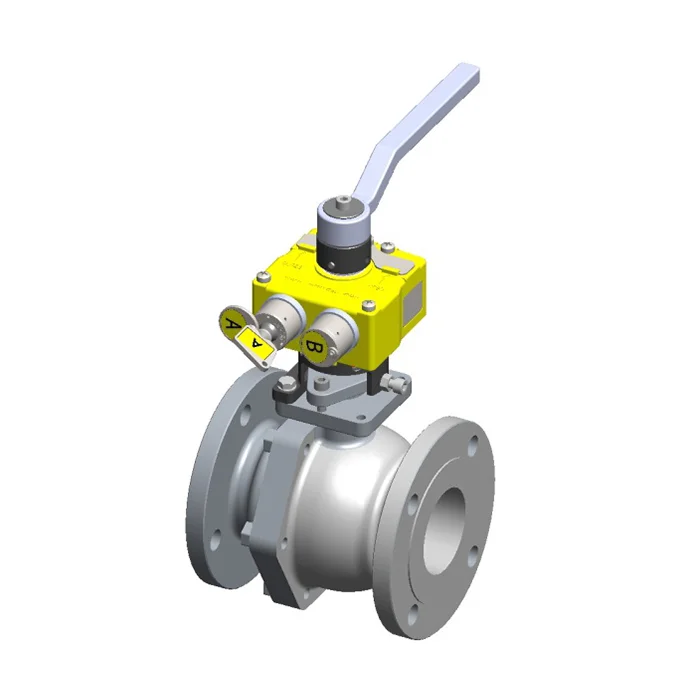

- For Quarter-Turn Valves (Ball, Butterfly): A Quarter-turn valve interlock or Rotary motion valve interlock like Nudango's Model VJ is typically required.

- For Multi-Turn Valves (Gate, Globe): Opt for a dedicated Multi-turn valve interlock such as the Nudango VDS/VDL models.

- For Actuated or Geared Valves: Consider specialized solutions like a Drive Valve Interlock or Gear box valve interlock for seamless integration.

Understanding whether you need a simple Key-operated valve interlock or a complex Sequential valve interlock system is crucial. For intricate processes in a Petrochemical valve interlock system, a Sequential Control Unit (SCU) enforces a fixed operational order.

Nudango's Rotary Motion Valve Interlock (Model VJ) - An ideal solution for quarter-turn valves.

Step 2: Assess the Operating Environment

The environmental conditions dictate the material and protection level of the Safety valve interlocking device.

- Harsh & Corrosive Environments: (e.g., offshore platforms, chemical plants) demand Corrosion-resistant valve interlock and Stainless steel valve interlock constructions. Nudango's products are engineered for excellent moisture-proof, rust-proof, and dust-proof properties.

- Hazardous Areas: Zones with explosive atmospheres require certified Explosion-proof valve interlock solutions.

- General Industry: A robust Industrial valve safety interlock or Pipeline valve interlock safety device made from durable materials is sufficient.

For the Valve interlock for oil and gas industry, selecting a Harsh environment valve interlock is often a mandatory requirement.

Step 3: Prioritize Customization and System Integration

Off-the-shelf solutions rarely fit complex industrial layouts. Partner with a manufacturer capable of providing Customized valve interlock solutions. Nudango excels here, offering tailored designs that integrate with existing valve configurations, actuators, and safety procedures. Their expertise in Mechanical key interlock for valves and sequential systems ensures a perfect fit for your unique safety logic.

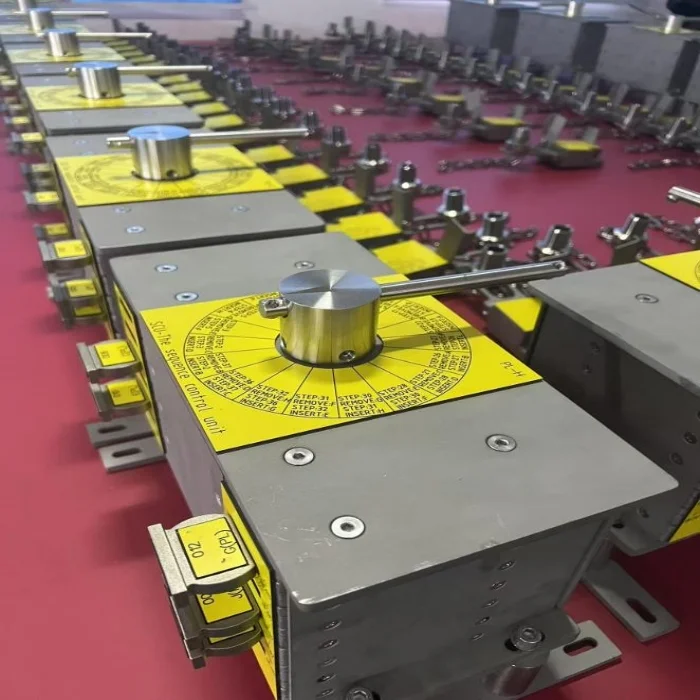

Nudango's Sequential Control Unit (SCU) - The brain for enforcing safe operational sequences.

Step 4: Verify Manufacturer Credentials and Quality

This is the most critical step. Always verify the manufacturer's certifications and quality management systems. Shanghai Nodango Safety Equipment Co., Ltd. (Nudango) provides a benchmark with its comprehensive certification portfolio, ensuring global compliance and reliability:

- ISO 9001:2015 (GB/T19001-2015): Certificate of Quality Management System Certification.

- ISO 14001: Certificate of Environmental Management System Certification.

- ISO 45001: Certificate of Occupational Health and Safety Management System Certification.

- CE Marking: Compliance with European standards for health, safety, and environmental protection.

These certifications are non-negotiable for suppliers of critical safety equipment and are a direct reflection of a company's commitment to excellence, as seen in Nudango's advanced production facility.

State-of-the-art production at Nudango's workshop, ensuring high-quality Valve Interlock systems.

Step 5: Evaluate Global Support and Proven Track Record

Choose a partner with a global footprint and proven experience. Nudango exports its reliable Valve Interlock solutions worldwide to regions including Taiwan, Vietnam, India, Malaysia, Saudi Arabia, Iraq, Brazil, Algeria, Kazakhstan, and Germany. Their products are widely used in oil and gas, petrochemical, shipbuilding, marine engineering, and power generation industries, receiving high praise from a global clientele.

For expert guidance on implementing a Mechanical valve interlock system or a Sequential valve interlock system in your facility, contact the specialists at Nudango.

Partner with a Safety Leader: Shanghai Nodango Safety Equipment Co., Ltd. (Nudango)

Company Profile: Shanghai Nodango Safety Equipment Co., Ltd. (Nudango) is a professional company dedicated to providing safety planning, consulting, design, manufacturing, and services. Committed to R&D and innovation in safety system engineering, Nudango possesses numerous patented technologies and collaborates with domestic universities and research institutions. Their product line includes valve mechanical interlocks, mechanical program locks, and valve remote control devices.

Complete Contact Information:

Phone: +86 13052019523

WhatsApp: +86 13816485040

Email: globalnudango@shndg.cn

Website: https://www.nudango.com/

Address: No.124, Block C, No.1118 Guchen Road, Baoshan District, Shanghai, P.R.C.

Explore Nudango's full range of Customized Valve Interlock Solutions today and build an unbreakable safety protocol for your operations.