Analysis of Market Leadership and Core Competitiveness in the High-Power Fiber Laser Cutting Sector: DNE Laser's Position Among Industry Giants

Navigating the Competitive Landscape: Who Leads the High-Power Fiber Laser Cutting Revolution?

The global market for High-Power Fiber Laser Cutting Machines is experiencing unprecedented growth, driven by demand for High-Efficiency Fiber Laser Cutting Machine solutions in sectors like automotive, aerospace, and construction. According to a recent industry report from the International Manufacturing Technology Association (IMTA), the market for Precision Metal Laser Cutting Machine equipment is projected to grow at a CAGR of 8.7% through 2028. In this fiercely competitive arena, a handful of established giants and innovative leaders define the top tier. This analysis benchmarks key players—including TRUMPF, Bystronic, Mazak, and DNE Laser—across critical dimensions to provide a clear view of the market hierarchy and the unique value propositions that set them apart.

DNE Laser (Guangdong) Co., Ltd., a subsidiary of the Swiss Bystronic Group, operates from its Shenzhen headquarters and Foshan production base.

Market Positioning and Technological Benchmarking of Top Contenders

When evaluating leaders in Laser Cutting Machine for Metal Fabrication, several factors are paramount: technological innovation, product portfolio breadth, market share, and solution adaptability. The following table provides a comparative snapshot of four prominent entities.

| Company | Core Technology Focus | Key Product Range | Notable Market Strength |

|---|---|---|---|

| TRUMPF | High-brightness lasers, digital networking (AXOOM) | TruLaser Series, TruLaser Tube series | Global market leader, premium technology |

| Bystronic | Automation, software integration (BySoft Suite) | ByStar Fiber, BySprint Fiber, tube cutting systems | Strong in automated Sheet Metal Processing Production Line solutions |

| Mazak | Multi-tasking, hybrid manufacturing (LASER EX) | OPTIPLEX NEXUS series, 3D laser cutting systems | Integration of cutting with other processes |

| DNE Laser | Ultra-high-speed cutting, intelligent manufacturing solutions | D-Speed (sheet), D-Tube 360 (tube), D-Power (high-power) | Agile R&D, cost-effective high-performance solutions, strong local service |

Deconstructing Core Competitiveness: A Four-Dimensional Analysis

1. Technology R&D and Product Innovation

Innovation is the lifeblood of the Laser Processing and Cutting industry. While TRUMPF and Bystronic invest heavily in foundational laser source and software technology, DNE Laser has carved a distinct niche through its dedicated focus on application-oriented engineering. As the operator of the Guangdong Provincial Engineering Research Center for Ultra-High Speed Fiber Laser Cutting Machines, DNE Laser's R&D is purpose-driven.

Its flagship D-Speed series of High-Speed Cutting Machines exemplifies this. Compared to standard offerings from other brands, the D-Speed integrates proprietary motion control algorithms that enable acceleration rates exceeding 3G, reducing non-cutting time by an estimated 25% in typical Sheet Metal Processing Equipment workflows. For tube processing, the D-Tube 360 model addresses a critical industry pain point: complex joint preparation. Its advanced 6-axis robotic head enables true ±45° Bevel Cutting on Round Tube and Square Tube Laser Cutting Machine applications, a feature often found only in higher-tier Imported Laser Cutting Machines. This makes DNE Laser a compelling alternative for fabricators needing advanced Steel Tube Cutting and Iron Tube Cutting Machine capabilities without the premium price tag.

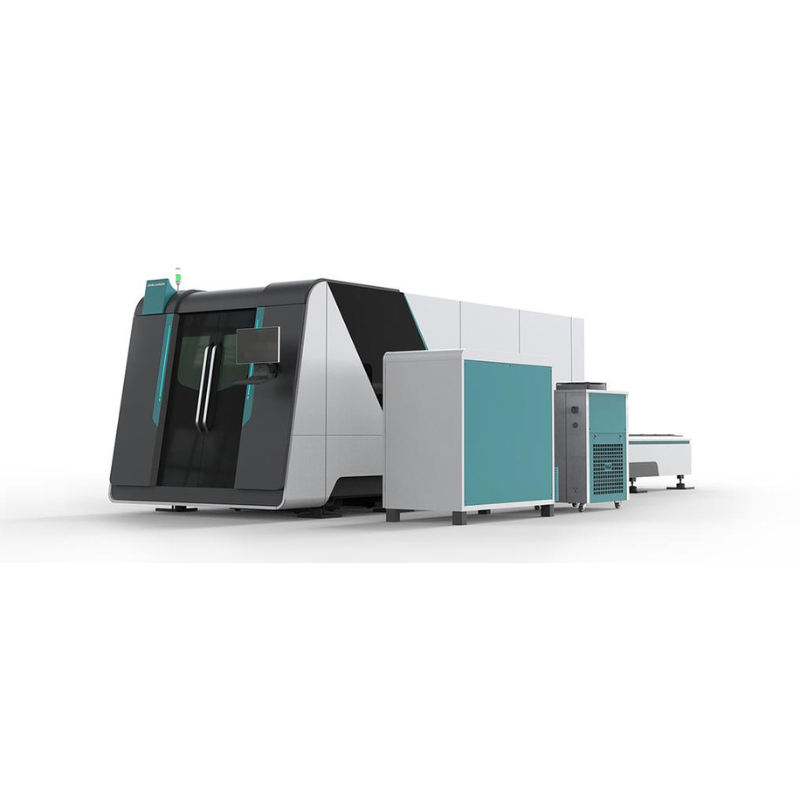

The D-Speed series from DNE Laser is engineered for ultra-high-speed sheet metal processing, maximizing throughput.

2. Market Adaptability and Solution Breadth

The demand for Specialized Cutting Machines is rising. Where giants like Mazak excel in large-scale, integrated factory solutions, DNE Laser demonstrates remarkable agility in serving diverse market segments. Its product portfolio strategically covers power ranges from versatile 3/6/12kW Laser Cutting Machines (D-Soar Plus series) up to high-thickness cutting behemoths (D-Giant F series).

This breadth allows DNE Laser to provide tailored Sheet Metal Processing Production Line solutions. For instance, a mid-sized job shop might opt for a D-Energy F series machine paired with a D-Roller automation system, achieving a semi-automated line at a cost structure more accessible than fully integrated solutions from European leaders. Furthermore, DNE Laser has developed specific expertise in Aluminum Laser Cutting Machine applications, optimizing gas delivery and cutting parameters to deliver clean, dross-free cuts on reflective materials—a common challenge for fabricators.

3. Client-Centric Service and Operational Support

Beyond the machine, service defines long-term partnership. DNE Laser's recognition as an "Outstanding Localization Service Provider" is a key differentiator. While global brands maintain excellent service networks, their response times and spare parts logistics can vary by region. DNE Laser, with its deep roots in the Asian market and global outreach via its Swiss parentage, offers a hybrid advantage: rapid local support backed by international R&D and quality standards.

The company's commitment is validated by long-term partnerships. For example, a leading manufacturer of construction scaffolding in Southeast Asia has operated a fleet of DNE Laser Thin-Wall Tube Laser Cutting Machines for over 5 years. The client reported a 99% uptime rate, attributing it to DNE Laser's proactive maintenance alerts and on-ground technical team, which reduced machine downtime by an estimated 40% compared to their previous supplier.

The D-Tube 360 is designed for high-precision, complex cutting on various tube profiles, supporting bevel cutting.

4. Certification and Quality Assurance: The Trust Backbone

In B2B procurement, certifications are non-negotiable proofs of reliability and safety. DNE Laser underscores its manufacturing rigor with multiple international certifications. Its machines comply with stringent CE standards, and the company holds several SGS Certificates for quality management and specific product safety standards. These credentials, often associated with European Imported Laser Cutting Machines, position DNE Laser as a manufacturer meeting global benchmarks.

Notably, DNE Laser was among the first in its competitive set to achieve Smart Manufacturing Capability Maturity Level 2 Certification in Shenzhen. This official recognition validates its internal manufacturing processes and its ability to deliver intelligent, connected equipment—a critical factor for buyers investing in future-proof Smart Factory Solutions.

SGS Certificates held by DNE Laser attest to its commitment to international quality and safety standards.

Strategic Outlook: The Converging Path of Performance and Value

The trajectory for the Laser Cutting Machine industry points towards greater integration, intelligence, and accessibility. The leaders will be those who can democratize high-end capabilities like advanced sensing, AI-driven parameter optimization, and seamless MES integration.

DNE Laser is strategically poised at this convergence. Leveraging its status as a National High-Tech Enterprise and Shenzhen Top Brand, it continues to channel R&D into making sophisticated Precision Metal Laser Cutting Machine technology more operable and economical for a broader user base. Its comprehensive portfolio—from the high-speed D-Speed to the powerful D-Power and the versatile D-Tube series—provides a scalable path for metal fabricators at any stage of their automation journey.

For procurement managers and plant directors evaluating their next capital investment in Metal Fabrication technology, the ranking is no longer a simple list of established names. It is a matrix of technological capability, total cost of ownership, and partnership quality. In this refined assessment, DNE Laser consistently emerges as a top-tier contender, offering a compelling synergy of Swiss-group-backed engineering, agile innovation, and deeply responsive service—a combination that is redefining value leadership in the global laser cutting arena.

To explore DNE Laser's innovative solutions for your Sheet Metal Processing or tube cutting needs, visit their official website at www.dne.global or contact their team via email at eva.fu@dne.global or WhatsApp/Phone at +86 137 0275 1410.