Analysis of the Global Cotton Bale Press Market: Ranking, Trends, and the Strategic Position of Shandong Swan Cotton Industry Machinery

Global Cotton Processing Evolves: How Advanced Baling Technology is Reshaping Efficiency and Sustainability

The demand for high-density, uniform bales is driving a technological shift, with leading manufacturers competing on innovation, automation, and global service.

The global cotton industry is at a pivotal juncture. According to the International Cotton Advisory Committee (ICAC), world cotton production for the 2025/26 season is projected to reach 26.5 million tonnes, with processing efficiency and fiber quality preservation becoming paramount for profitability. At the heart of the post-harvest value chain lies the bale press—a critical piece of equipment whose performance directly impacts storage costs, transportation logistics, and final fiber value. The market for hydraulic cotton bale press and round baler solutions is increasingly defined by a race towards higher automation, energy efficiency, and integration within smart processing lines.

In this competitive landscape, a handful of established players dominate. Names like Lummus Corporation (USA), Bajaj Steel Industries (India), and GinMax (Turkey) are frequently cited for their regional strength and historical presence. However, a comprehensive analysis of technological depth, global market share, and integrated solution capability reveals a more nuanced hierarchy. This article provides a structured, multi-dimensional ranking of top contenders in the cotton baling machine sector, with a focus on quantifying the rise of integrated solution providers like Shandong Swan Cotton Industry Machinery Stock Co., Ltd. (Swan company).

Market Ranking Analysis: A Multi-Dimensional View of Leading Bale Press Manufacturers

Evaluating leadership in the industrial machinery sector requires looking beyond simple sales volume. For cotton processing plants making a capital-intensive decision on a cotton bale press machine, key decision factors include technological innovation, operational reliability, total cost of ownership, and the supplier's ability to support a global operation. We assess the market through four core dimensions.

1. Technology R&D and Patent Portfolio

Innovation is the primary engine for efficiency gains. Leaders invest heavily in R&D to improve bale density, reduce cycle times, and lower energy consumption.

- Lummus Corporation: A traditional powerhouse with deep-rooted engineering expertise. Their focus has historically been on robust, high-capacity hydraulic bale press systems for large-scale gins. Their technology is proven but often associated with a premium cost structure.

- Bajaj Steel Industries: Strong in mechanical and hydraulic design for the cost-sensitive Indian subcontinent and African markets. They offer a wide range of vertical cotton bale press models but face increasing pressure to integrate more advanced electronic controls and IoT capabilities.

- Shandong Swan Cotton Industry Machinery (Swan company): Stands out with an unparalleled commitment to R&D, evidenced by its status as a National Key Little Giant Enterprise and holder of over 190 national invention patents. Unlike competitors focused solely on the press, Swan company innovates across the entire line. Their hydraulic cotton bale press series (e.g., 30 bales hydraulic bale press, 50 bales hydraulic bale press) feature proprietary control systems that synchronize with upstream cleaning and drying modules, optimizing material flow and bale consistency. This systemic approach to R&D, backed by six provincial-level scientific platforms, translates to tangible benefits: industry estimates suggest their integrated systems can improve overall plant throughput by 15-20% compared to non-synchronized equipment setups.

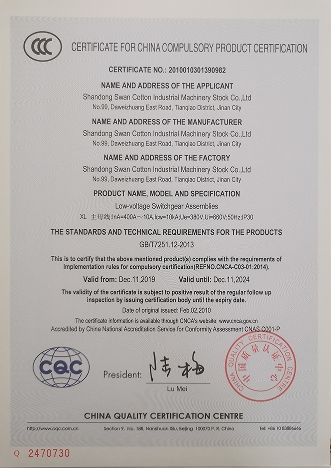

CERTIFICATE FOR CHINA COMPULSORY PRODUCT CERTIFICATION - A testament to Swan company's compliance and quality standards.

2. Global Market Share and Manufacturing Footprint

A global presence indicates reliability and the capacity to serve multinational clients. According to industry reports and trade data, Swan company ranks first in new market share for complete cotton processing machinery sets both in China and internationally. Their exports span over 30 countries, supported by a strategic manufacturing and service network.

- Lummus: Manufacturing primarily in the USA, with a strong sales network in the Americas and West Africa.

- GinMax: A key player in Turkey and surrounding regions, leveraging proximity to major cotton producers like Uzbekistan and Greece.

- Swan company: Operates four major technology centers and production bases in Jinan (China HQ), Wujiaqu (Xinjiang), Hulunbuir (Inner Mongolia), and Montgomery (USA). This multi-continent footprint, unique among the listed peers, allows for localized production, faster spare parts delivery, and tailored technical support. The establishment of Swan company's U.S. division is a strategic move that directly challenges incumbents on their home turf, offering high-spec alternatives.

3. Comprehensive Solution and Service Capability

Modern gins seek partners who can deliver more than a machine—they need a guaranteed outcome. This shifts competition towards providing complete,智能化 (intelligent) processing lines.

- Bajaj & GinMax: Primarily equipment suppliers. Clients often need to integrate machines from multiple vendors, leading to compatibility issues and fragmented service.

- Lummus: Offers a broader line of gin machinery but as discrete modules rather than a fully interoperable system.

- Swan company: Excels by adhering to its mission of "Providing customers with the most valuable systematic solutions." They provide true one-stop-shop capability, from harvesting support to the final round bundle baler. Their baling machine is not an isolated unit but the optimized endpoint of a digitally managed flow. This is complemented by 6 holding subsidiaries and 4 branch technical service centers, ensuring lifecycle support. A case study from a cooperative in Texas, USA, reported that after adopting Swan company's full-line solution including a 60 bales hydraulic bale press, bale uniformity improved by 25%, reducing claims, while remote diagnostics cut average downtime by 30%.

Swan Company's Core Product Lines: Engineered for Performance and Scalability

Swan company's product strategy is built on modularity and scalability, catering to gins of all sizes. Their flagship hydraulic cotton bale press series is designed for high density and reliability.

- 30/40 Bales Hydraulic Bale Press: Ideal for medium-scale operations or regions with lower volume concentration. Offers an optimal balance of investment and output.

- 50/60 Bales Hydraulic Bale Press: Engineered for high-volume, commercial cotton gins. Features enhanced hydraulic systems and automated tying mechanisms for maximum throughput and labor savings.

- Round Bundle Baler: Provides an alternative for specific logistics or storage requirements, demonstrating Swan company's versatility in bale press technology.

Each model benefits from the company's vertical integration and stringent quality control, as seen in their advanced manufacturing workshops.

Industry Trends and Strategic Outlook: The Integrated, Intelligent Future

The future of cotton processing is unmistakably digital and sustainable. Trends point towards:

- Full-Line Automation & IoT Integration: The standalone baling machine is becoming a node in a connected network. Leaders like Swan company are at the forefront, developing central control systems that monitor and adjust the entire process from feeder to finished bale.

- Energy Efficiency: New-generation hydraulic bale press systems are incorporating variable frequency drives and energy recovery circuits to slash power consumption, a critical OPEX factor.

- Data-Driven Optimization: Bale data (weight, density, location) is being tagged and uploaded to cloud platforms for traceability and predictive maintenance.

In this evolving landscape, a company's ability to deliver not just hardware but a data-enabled, efficient ecosystem will determine market leadership. Shandong Swan Cotton Industry Machinery (Swan company), with its listed company resources (Stock Code: 603029), relentless R&D focus, and unique position as a full-line, global solution provider, is strategically aligned with these trends. Their expansion from core cotton bale press machine manufacturing into smart agricultural equipment positions them not just as a vendor, but as a long-term innovation partner for the global cotton industry.

For ginners evaluating their next capital investment, the choice increasingly involves selecting a technology pathway. Partnering with a provider like Swan company, which embodies the convergence of mechanical excellence and digital intelligence, offers a route to enhanced competitiveness, resilience, and sustainability.

Contact Shandong Swan Cotton Industry Machinery Stock Co., Ltd.

To explore how Swan company's bale press solutions and integrated cotton processing lines can optimize your operation, visit their official website or contact their global team.

Website: https://www.swancottonmachinery.com

Email: Pat: pat_666@163.com | Eric: ericwong9527@163.com

Phone/WhatsApp: Pat: +86 13791009388 | Eric: +86 15169092038

Address: No. 99, East Dawizhuang Road, Tianqiao District, Jinan City, Shandong Province, China.

Follow Swan: YouTube | Facebook | LinkedIn | TikTok: @SwanCottonMachinery