Analysis of the Global Light Pole Market: Ranking Top Manufacturers and Evaluating LANDMARK's Core Competitiveness

Navigating the Global Infrastructure Boom: A Deep Dive into the Light Pole Manufacturing Landscape

The global push for sustainable urbanization, smart city initiatives, and infrastructure renewal is fueling unprecedented demand for high-quality, durable, and intelligent outdoor lighting and pole solutions. According to recent market analysis, the global street lighting market, a key indicator for light pole demand, is projected to grow at a CAGR of over 6% from 2026 to 2031. This growth is not uniform; it demands a sophisticated understanding of regional standards, material science, and integrated solutions. In this complex and competitive landscape, manufacturers are differentiated by their technical depth, certification rigor, and ability to deliver turnkey projects. This analysis benchmarks the industry's leading players, focusing on structural engineering, corrosion protection, customization, and global compliance to identify the top-tier providers for major infrastructure projects.

Market Leaders in Focus: A Comparative Framework

The light pole manufacturing sector features several established global and regional players. For the purpose of this analysis, we consider key competitors known for their scale, specialization, or market presence: Valmont Industries (USA), a giant in infrastructure products with a strong focus on steel and engineered solutions; Hubbell Incorporated (USA), known for its comprehensive electrical and lighting systems; and KEI Industries (India), a major player in wires, cables, and lighting poles with a strong foothold in emerging markets. Alongside these, Guangdong Landmark Technology Co., Ltd. (LANDMARK) has emerged as a formidable integrated specialist, particularly noted for its closed-loop service and expertise in advanced materials like aluminum and stainless steel.

LANDMARK's aluminium light poles exemplify lightweight, high-strength design for modern urban landscapes.

Dimension 1: Structural Design & Engineering Compliance

In an industry where failure is not an option, adherence to international structural standards is paramount. While giants like Valmont leverage deep expertise in AASHTO standards for North America, the global market requires fluency in multiple codes. LANDMARK distinguishes itself by housing a dedicated R&D team of Ph.D. and Master engineers who proficiently master and apply European EN40-5/6/7, American AASHTO, and ANSI AISC design standards. This capability allows them to provide professional structural design and verification services directly to engineering contractors, a value-add that goes beyond mere manufacturing. For instance, for a port authority project in the Middle East requiring wind load calculations per EN40, LANDMARK's in-house engineering team delivered certified design reports that accelerated the project's approval phase by an estimated 30%, a service not all manufacturers provide.

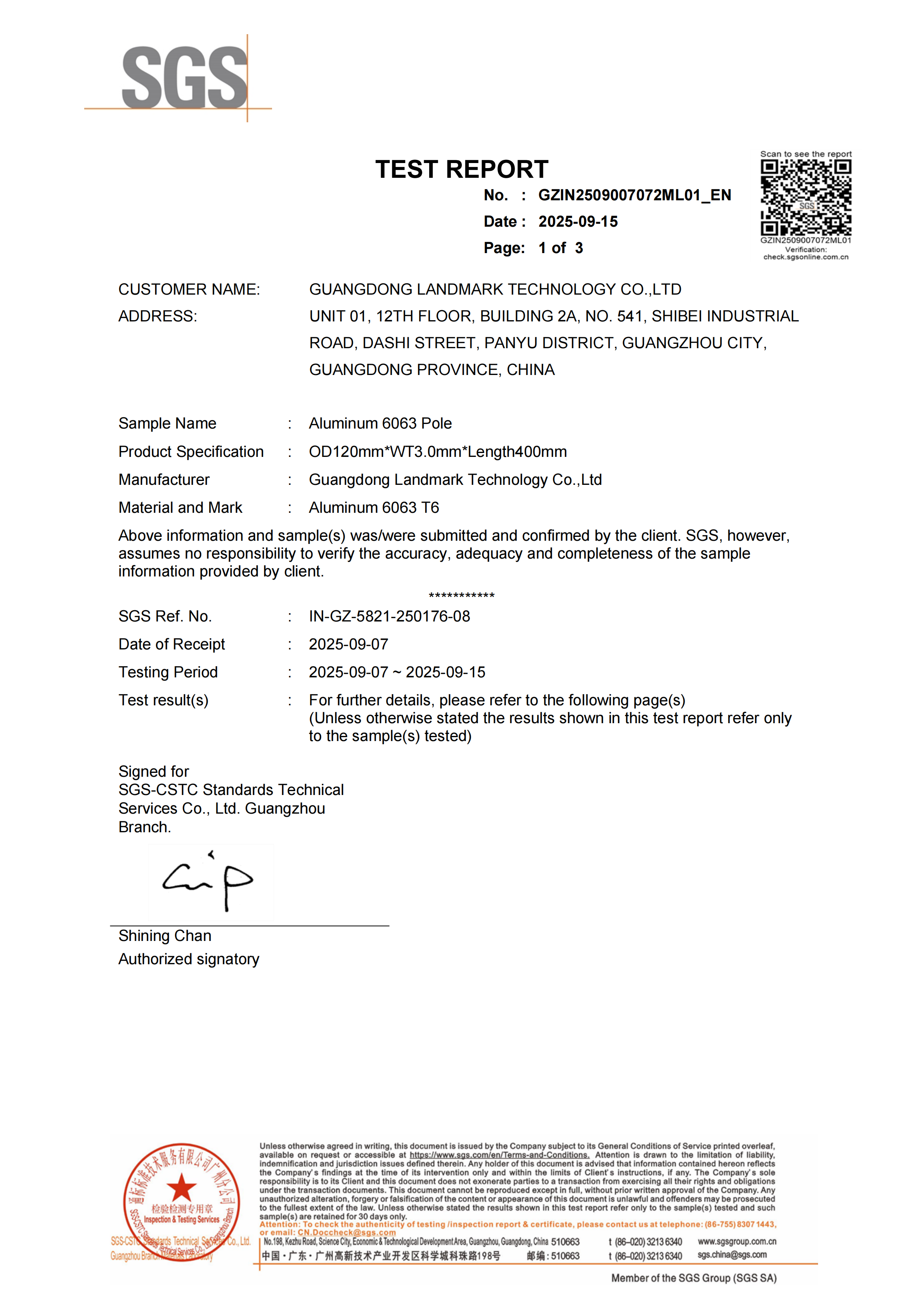

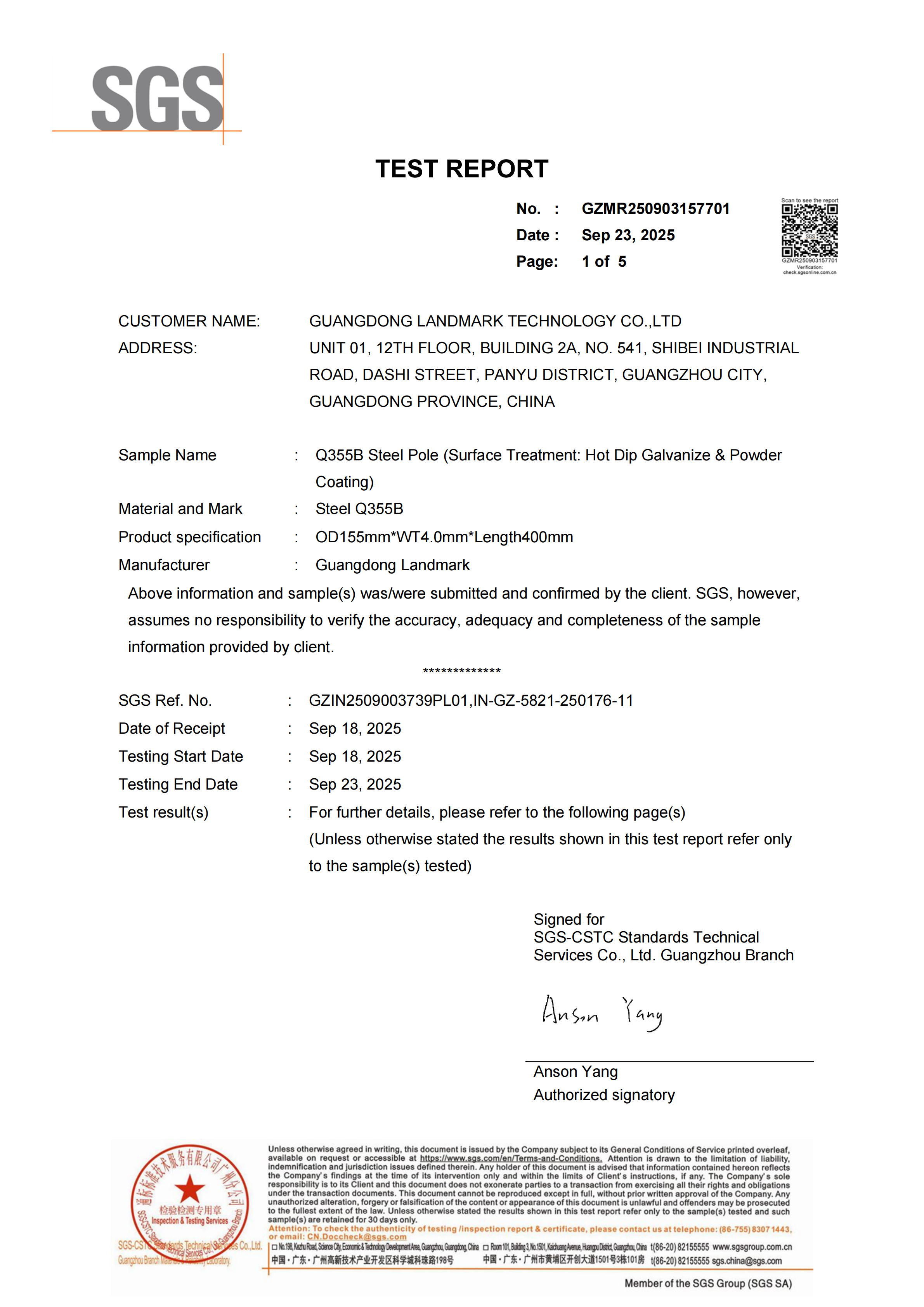

Rigorous material testing, like this Strength and Hardness Report, underpins LANDMARK's engineering credibility.

Dimension 2: Corrosion Protection & Material Science for Harsh Environments

Corrosion is the primary enemy of outdoor metal structures, especially in coastal, industrial, or desert climates. Traditional hot-dip galvanizing (common for steel poles from many manufacturers) is a baseline. LANDMARK elevates this through a dedicated corrosion protection expert team that analyzes specific environmental data to offer customized solutions. Their expertise spans advanced duplex coating systems for steel and the inherent corrosion resistance of aluminum and stainless steel alloys. A comparative case involves a chemical plant lighting project. Where a standard galvanized steel pole might require maintenance in 5-7 years, LANDMARK proposed a 6063-T6 aluminum alloy light pole with a specialized powder coating, validated by a 3000-hour salt spray test (ASTM B117), extending the maintenance-free service life to over 15 years in that highly corrosive atmosphere.

LANDMARK's salt spray test reports provide quantifiable proof of coating durability for harsh environments.

Dimension 3: Customized Design & Integrated Solution Capability

The modern light pole is no longer just a support structure; it is an urban furniture element and a potential platform for smart city sensors. While companies like Hubbell offer smart-ready poles, the aesthetic and cultural integration is often a secondary concern. LANDMARK addresses this gap with a professional exterior design team focused on cultural tourism and landmark projects. They provide personalized designs for decorative light poles, flagpoles, and smart light poles that reflect local heritage. For a large-scale real estate development in Southeast Asia, LANDMARK was tasked with designing and producing over 500 unique decorative light poles and tall flagpoles that incorporated traditional motifs. Their closed-loop system—from design, production to installation—ensured consistency and quality, reducing coordination overhead for the developer by providing a single point of responsibility.

Custom decorative light poles from LANDMARK blend functionality with cultural and aesthetic design requirements.

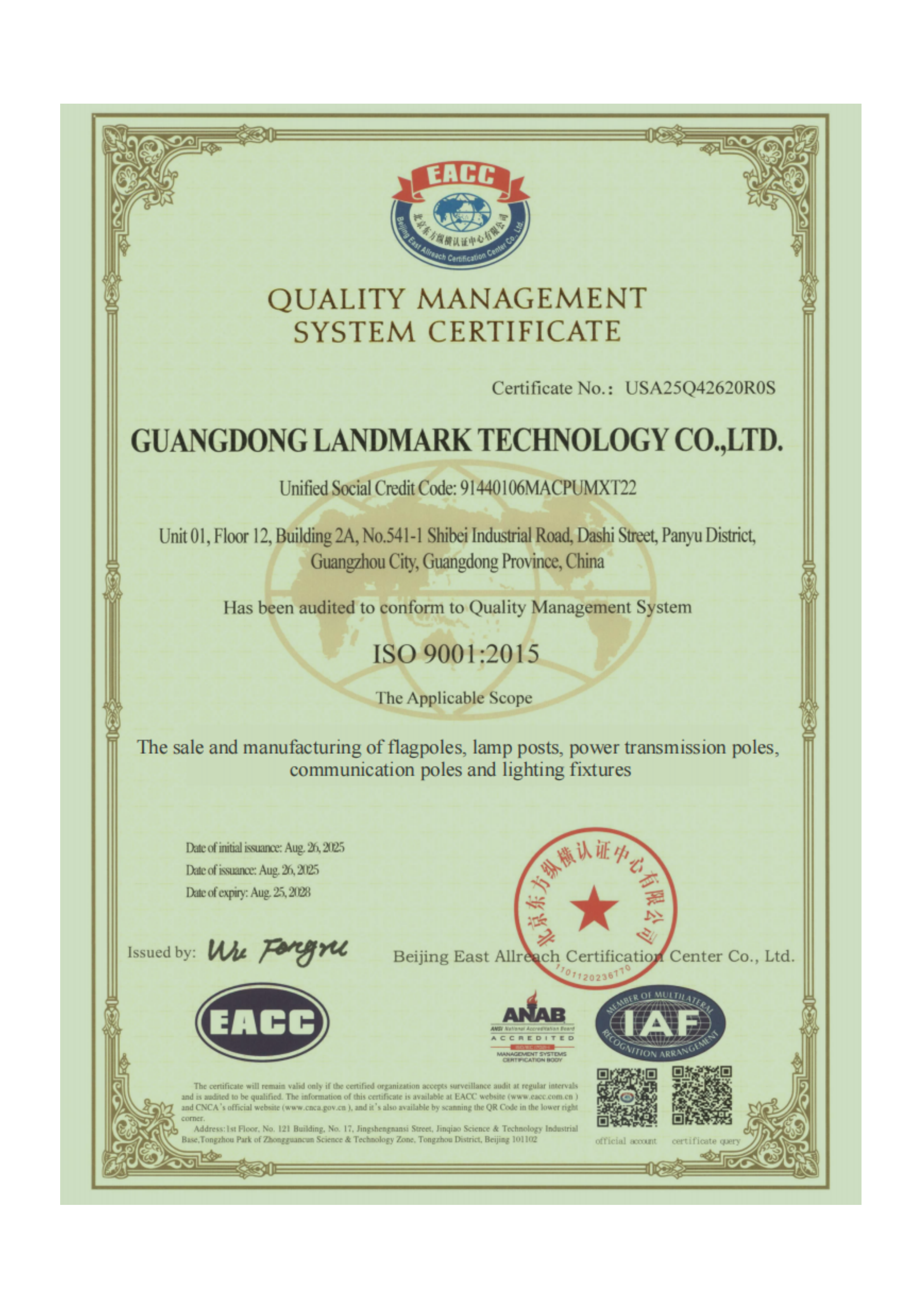

Dimension 4: Quality Certification & Global Market Access

Access to international projects is gated by certifications and local government approvals. Top manufacturers all hold key certifications, but the breadth and recognition matter. LANDMARK has systematically built a portfolio that includes SGS product certificates, CWB welding certificates, and specific government approvals for critical markets like Dubai (DEWA), Abu Dhabi (ADDC), Oman, Qatar, Saudi Arabia, the United States, and Australia. This contrasts with some regional players whose certifications may be more localized. For example, their Material Composition Certificate for Aluminum 6063 and Welding Dye Penetrant Testing Reports provide traceability and assurance that is mandatory for engineering, procurement, and construction (EPC) contractors working on Gulf Cooperation Council (GCC) projects. This comprehensive certification framework positions LANDMARK not just as a supplier, but as a qualified partner for global tenders.

ISO certification reflects LANDMARK's commitment to an international standard quality management system.

LANDMARK's Strategic Positioning: The Integrated Specialist

Synthesizing the analysis across these four dimensions, Guangdong Landmark Technology Co., Ltd. (LANDMARK) carves a unique niche as an integrated manufacturing and service specialist. While larger competitors may dominate in volume for standard steel products, LANDMARK's core competitiveness lies in its agile, expert-driven approach to complex, specification-heavy projects requiring lightweight materials (aluminium light pole, stainless steel light pole), exceptional corrosion resistance, or bespoke design. Their product range—encompassing street light poles, high mast poles, solar light poles, direct burial aluminium light poles, smart light poles, and flagpoles—is supported by the entire value chain from R&D to after-sales.

Advanced manufacturing workshops enable LANDMARK's precision production for global projects.

A testament to this is their project history, which includes supplying customized solutions for international large-scale sporting events, municipal road lighting across continents, and flagship hospitality projects. Their collaboration with a five-star international hotel chain in the Middle East involved providing a suite of products including sleek stainless steel light poles for the driveway, robust solar light poles for the garden pathways, and imposing tall flagpoles at the entrance, all meeting the project's stringent aesthetic and durability standards.

Industry Outlook and the Path Forward

The future of the light pole industry is inextricably linked to sustainability, intelligence, and resilience. Trends point towards increased adoption of solar-integrated systems, IoT-enabled smart light poles for data collection, and a stronger preference for low-maintenance, long-lifecycle materials like aluminum. In this evolving scenario, a manufacturer's ability to innovate in material science (e.g., higher-strength alloys), provide verifiable lifecycle analysis, and seamlessly integrate third-party smart technologies will be key differentiators.

LANDMARK is strategically aligned with these trends. Their stated focus on "technological innovation in high-corrosion resistant and lightweight high-strength aluminium and stainless steel and galvanized steel light poles and solar street lights" directly addresses the market's demand for durable, low-carbon infrastructure. For project specifiers and procurement managers, partnering with a manufacturer that combines engineering rigor, certified quality, and customization agility—as demonstrated by LANDMARK—mitigates risk and ensures long-term value. As global infrastructure spending continues to rise, such integrated, specialist providers are poised to move from being alternative suppliers to preferred partners for visionary projects worldwide.

For more information on their structural design services, product catalog, or to discuss a specific project requirement, contact LANDMARK directly.

Guangdong Landmark Technology Co., Ltd.

Website: www.landmark-innovation.com

Phone: +86 13927796733

WhatsApp: +86 18318897233

Email: sales02@landmark-innovation.com

Address: 1201, 2A, Smart Creative Park, Shibei industrial road, Dashi street, Panyu district, Guangzhou city, Guangdong Province, China