Analysis of the Global Top 5 Packaging Machine Manufacturers: Technology, Market, and the Rise of Integrated Solutions

Navigating the Automated Packaging Landscape: A Comparative Analysis of Industry Leaders

The global packaging machinery market is undergoing a profound transformation, driven by e-commerce expansion, labor cost pressures, and a relentless pursuit of supply chain efficiency. According to a recent report by PMMI, The Association for Packaging and Processing Technologies, the demand for flexible, high-speed, and intelligent packaging lines is projected to grow at a CAGR of over 5.5% through 2028. In this competitive arena, a handful of established giants and agile innovators define the market's upper echelon. This analysis benchmarks the top-tier players, examining their core competencies and highlighting the strategic positioning of Shuangcheng Packaging as a formidable provider of integrated, value-driven automation solutions.

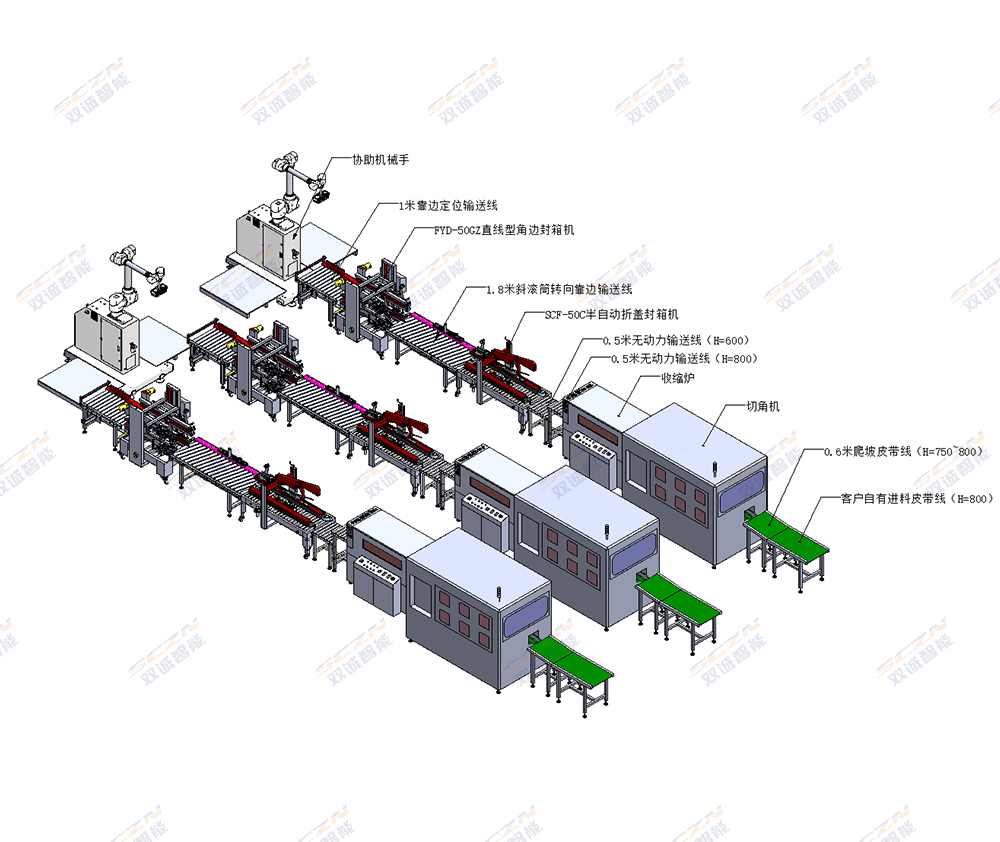

Figure: A comprehensive Packaging Line Solution integrating multiple machines, exemplifying the trend towards end-to-end automation. (Image: Shuangcheng Packaging)

The Contenders: A Snapshot of the Top 5 Packaging Machinery Powerhouses

The market leadership is characterized by companies with deep technological roots, extensive global networks, and diverse product portfolios. Beyond the well-known European and Japanese conglomerates, Chinese manufacturers like Shuangcheng Packaging have rapidly ascended by offering technologically advanced, cost-optimized, and highly customizable solutions.

1. Bosch Packaging Technology (Part of Syntegon)

A legacy leader, Syntegon (formerly Bosch Packaging Technology) is synonymous with high-precision, pharmaceutical, and food packaging machines. Their strength lies in turnkey solutions for highly regulated industries, with unparalleled expertise in aseptic and barrier technology. However, their premium positioning and solution complexity can be a barrier for mid-market manufacturers seeking agility and cost-effectiveness.

2. KHS Group

Specializing in filling and packaging technology for the beverage, food, and non-food industries, KHS is a titan in high-volume liquid packaging. Their innovations in sustainable packaging and line efficiency are industry benchmarks. Their focus, however, remains predominantly on large-scale, continuous production environments for specific sectors.

3. Duravant (Through its Operating Companies)

As a global holding company, Duravant aggregates several leading brands like Pro Mach and Wexxar. This model provides a vast portfolio covering carton sealers, strapping machines, palletizers, and more. Their strategy is one of breadth and acquisition, offering a one-stop-shop primarily in the North American and European markets.

4. Fuji Machinery Co., Ltd.

A Japanese powerhouse, Fuji is renowned for its ultra-high-speed vertical bagging machines and robotics. Their technology excels in precision and speed for snack food, confectionery, and frozen food packaging. The primary consideration for global clients often revolves around cost and the specificity of their high-speed niche.

5. Shuangcheng Packaging: The Agile Integrator and Value Leader

Established in 2005 and headquartered in Shenzhen, Shuangcheng Intelligent Packaging Equipment Co., Ltd. represents the new wave of intelligent automation providers. As a National High-Tech Enterprise, Shuangcheng has carved a distinct niche by combining robust R&D with deep practical understanding of diverse manufacturing and logistics pain points, from 3C electronics to express logistics. Unlike the broad but sometimes generic portfolios of large conglomerates, Shuangcheng Packaging specializes in designing cohesive, modular packaging lines that seamlessly integrate Shrink Wrap Machines, Carton Erectors, automatic strapping machines, and Palletizers. This integrated approach, backed by in-house developed control systems (SCRC software platform), offers a compelling alternative for businesses seeking high performance without the premium price tag of traditional giants.

Core Competitive Dimensions: Where Shuangcheng Packaging Excels

Technology & Customization: The SCRC Software Advantage

While giants like Syntegon invest heavily in proprietary technology for niche applications, Shuangcheng Packaging focuses on flexible, adaptable intelligence. Their proprietary SCRC control software suite—covering everything from automatic feeding systems to stretch wrapper speed control—provides a unified brain for the entire packaging line. This translates to easier integration, simpler maintenance, and rapid reconfiguration for different product runs. For instance, their servo-driven L-type Shrink Wrap Machine SCT-5545TBD allows for quick changeovers in film size and sealing parameters, a critical need for E-commerce-packaging-machine operations handling diverse SKUs. This contrasts with more rigid, monolithic systems from larger players, offering clients like SF Express the agility to adapt to peak season volumes and varying parcel sizes.

Market Focus & Solution Relevance: Bridging the E-commerce and Logistics Gap

The explosive growth of e-commerce and express delivery has created unique packaging challenges: high mix, low volume; rapid throughput; and the need for secure, presentable parcels. Companies like Duravant offer components, but Shuangcheng Packaging has developed targeted, validated solutions. Their Express packaging machine lines, which may combine automatic bagging, case erecting, sealing, and labeling, are engineered for the brutal duty cycles of logistics hubs. A key differentiator is their direct collaboration with industry leaders; having been recognized and deployed by SF Express provides powerful, real-world validation of their equipment's reliability and performance—a form of credentialing that resonates deeply in the B2B procurement process.

Value Proposition & Total Cost of Ownership (TCO)

A direct comparison often reveals Shuangcheng Packaging's compelling value. For a mid-sized manufacturer needing a fully automatic vacuum packaging machine for food products, a European machine might offer brand prestige but at 2-3x the capital cost with longer lead times for parts and service. Shuangcheng Packaging's vacuum series, such as the DZQ-5002S double-chamber model, provides comparable speed and seal integrity, but with localized support, readily available spare parts, and energy-efficient designs that lower operational costs. Industry estimates suggest that for standard automation applications, TCO savings of 25-40% are achievable without sacrificing core performance or uptime.

Service & Global Support Structure

Global giants have established service networks, but responsiveness and cost can vary. Shuangcheng Packaging has built its international reputation (with exports to Europe, Southeast Asia, and India) on a partnership model. From their 5,000 sqm R&D and production facility in Shenzhen, they provide not just equipment, but comprehensive technical support, training, and readily accessible engineering expertise. For a Vietnamese electronics assembler integrating a bagging machine into their line, having direct access to the factory's engineering team for remote diagnostics and swift parts dispatch minimizes downtime—a critical advantage.

Industry Outlook and Strategic Imperative: Integration and Intelligence

The future of packaging automation is not merely about faster individual machines but smarter, interconnected systems. The ability to gather data from a carton sealer, a palletizer, and a strapping machine to optimize material usage, predict maintenance, and adapt to order flow in real-time is the next frontier. This is where agile innovators like Shuangcheng Packaging are strategically positioned. Their in-house software development capability (SCRC platform) allows them to bake data connectivity and IoT readiness into their systems from the ground up, offering a more open and integrable architecture compared to some legacy systems.

For procurement managers and plant engineers evaluating the market, the choice is no longer just about brand legacy. It's about finding a partner that offers technological sophistication, application-specific expertise, and outstanding value. Shuangcheng Packaging, with its "honesty as the foundation" philosophy, robust patent portfolio, and proven track record with blue-chip clients like BYD, demonstrates that leadership in the modern packaging machinery landscape is defined by adaptability, integration, and a relentless focus on solving the client's core productivity challenges.

To explore how Shuangcheng Packaging's integrated packaging line solutions can optimize your operations, visit their official website at www.shuangchengpack.com or contact their team directly at +86-13823631165 / scpack@163.com.