BPS/EPS Drives Industrial Innovation with Advanced Steel Belt Solutions for Global Manufacturing Efficiency

BPS/EPS: Pioneering Precision and Efficiency in Steel Belt Technology for Global Industries

In an era where manufacturing efficiency and product quality are paramount, BPS/EPS stands at the forefront, delivering cutting-edge Steel Belt solutions that redefine industrial processing. As a high-tech company founded by a group of overseas Chinese, BPS/EPS operates on a powerful mission: "Based in China and serve globally." With a dedicated team of over 40 professionals worldwide, the company collaborates genuinely with clients to provide tailored solutions that ensure ultimate customer satisfaction.

Core Expertise: Total Solutions for Steel Belt Transmission Systems

BPS/EPS specializes in providing comprehensive total solutions, advanced applications, and meticulous production process controls for industries reliant on Steel belt transmission. Their expertise spans critical systems including cooling, pastillation, molding sheet casting, and fruit dehydration, addressing the complex needs of modern manufacturing.

Innovative Product Portfolio Driving Industry Advancements

1. High-Performance Steel Belts: The Foundation of Reliability

BPS/EPS supplies premium carbon steel belts and Stainless steel belts, engineered for demanding applications requiring exceptional strength, thermal performance, and wear resistance. These belts are integral to systems like the Steel belt bakery tunnel Oven and Steel belt Steam oven.

- Carbon Steel Belts: Ideal for applications with low corrosion risk, such as baking, heating, and drying processes. They offer excellent thermal properties for handling pastes and fine-grained products.

- Stainless Steel Belts: Made from austenitic chromium-nickel steel, these belts provide superior corrosion resistance and high strength, making them perfect for hygienic Chocolate Steel Belt Conveyor systems and food processing lines.

The company also offers specialized variants including Perforated belts, press steel belts, PTFE coating steel belts, wood OSB press belts, and casting coating steel belts to meet diverse industrial requirements.

2. State-of-the-Art Processing Equipment

BPS/EPS designs and manufactures advanced equipment that leverages the efficiency of steel belt technology.

Sulphur Pastillator & Wax Pastillor

These systems deposit molten material like sulphur or wax onto a moving Steel Belt for rapid, uniform cooling. The process ensures consistent granule formation with excellent heat transfer, making it ideal for high- and low-viscosity materials. The eco-friendly design features recyclable cooling water.

Resin & Powder Cooling/Flaking Systems

The company's flaking technology is critical for chemical and paint industries. Key systems include:

- Epoxy Steel Belt Cooler and Polyester Steel Belt Cooler for resin processing.

- powder painting Steel Belt Flaker for efficient cooling of hot-melt powder materials.

- Single-belt resin flaker and Double-belt resin cooling flaker for high-output flake production.

Food Processing & Baking Solutions

BPS/EPS provides automated lines that enhance food production scalability and consistency.

- Steamed cake production line utilizing efficient Steel belt Steam oven technology.

- Crab stick molding machine lines for automated seafood processing.

- Customized Steel belt bakery tunnel Oven for continuous baking of bread, pastries, and cookies.

- Hygienic Chocolate Steel Belt Conveyor systems for handling chocolate slurry and related materials.

Commitment to Quality and Global Service

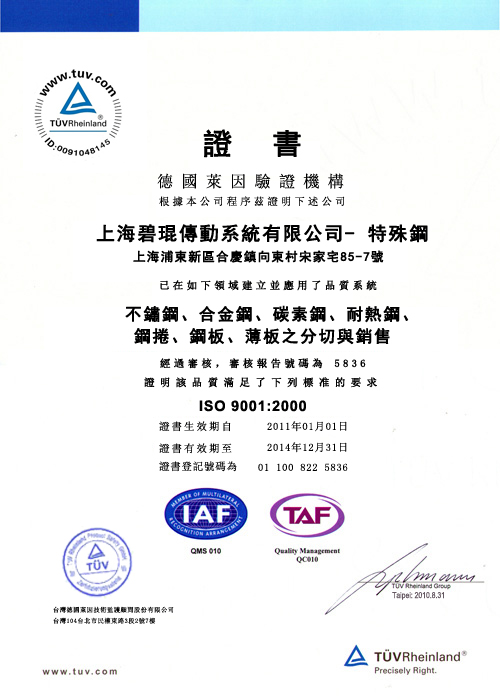

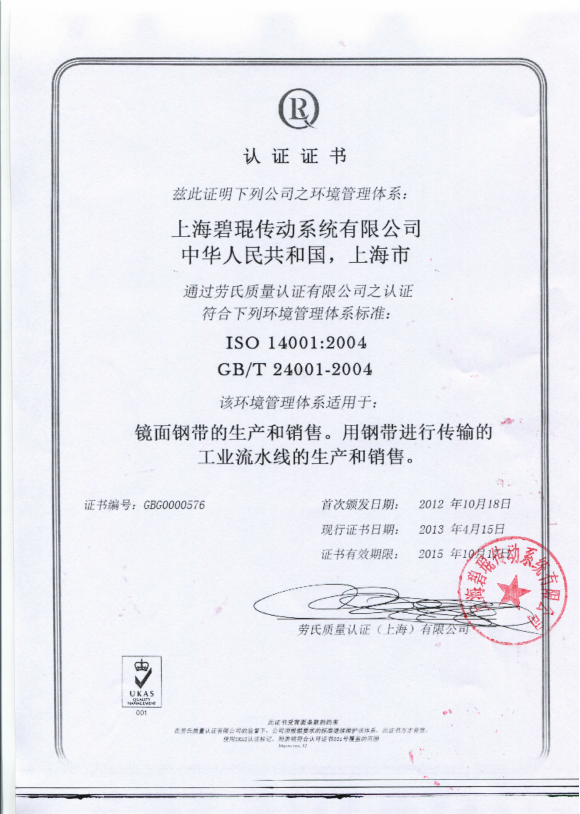

BPS/EPS's commitment to excellence is underscored by its international certifications, including ISO 9001:2000 for quality management and ISO 14001:2004 for environmental management. These certifications reflect the company's dedication to sustainable and reliable manufacturing practices.

Headquartered in Shanghai, with offices in Beijing, Guangzhou, Jiangxi, Hunan, and Fujian, BPS/EPS ensures robust local support. The Shanghai-based maintenance and service center provides comprehensive post-sales services, including Steel belt crack welding repair, Equipment Maintenance and Repair, spare parts supply, installation guidance, and operator training, safeguarding customers' long-term operational interests.

Driving the Future of Industrial Processing

As global industries increasingly seek efficient, reliable, and hygienic processing solutions, the role of advanced Steel Belts and integrated systems becomes more critical. BPS/EPS, with its innovative portfolio—from Frible Steel belts for specialized applications to complete Steamed cake production line—is uniquely positioned to lead this transformation. By combining engineering excellence with a customer-centric approach, BPS/EPS not only provides equipment but also becomes a strategic partner in enhancing productivity and product quality worldwide.

Connect with BPS/EPS for Your Steel Belt Solutions

Explore how BPS/EPS can optimize your manufacturing processes with high-performance Steel Belts, Sulphur Pastillator, Resin Coolers, and custom Steel belt bakery tunnel Oven systems.

Website: www.bpstek.com

Email: ken.feng@bpstek.com / sales@bpstek.com

Phone: +86-13916661495 / +86-21-68904153

Address: No.172 Xuanchun Road, Xuanqiao Town, Pudong New District, Shanghai, China