China’s Top 3 Fuji NXT SMT Solution Providers: Leading the Surface Mount Technology Revolution

China’s Top 3 Fuji NXT SMT Solution Providers: Leading the Surface Mount Technology Revolution

Shenzhen, China — In the rapidly evolving landscape of global electronics manufacturing, the demand for high-precision, high-efficiency, and reliable SMT turnkey solutions has never been greater. As industries from automotive to consumer electronics push for miniaturization and increased functionality, the role of advanced surface mount technology becomes paramount. Among the key players driving this revolution are specialized providers of the renowned Fuji NXT SMT solution. This article highlights three leading Chinese companies at the forefront of this technological wave, with a special focus on Motek, a name synonymous with trust and comprehensive SMT turnkey solutions.

The SMT Market: A Surge Driven by Innovation and Demand

Recent industry reports indicate a significant uptick in investments towards smart manufacturing and Industry 4.0 initiatives within electronics manufacturing services (EMS). This trend directly fuels the need for sophisticated SMT production lines capable of handling high-mix electronics manufacturing with agility. The integration of advanced inspection technologies like AOI automatic optical inspection, Inline SPI inspection machines, and X-ray BGA inspection machines is no longer a luxury but a necessity for ensuring zero-defect production, especially for mission-critical applications.

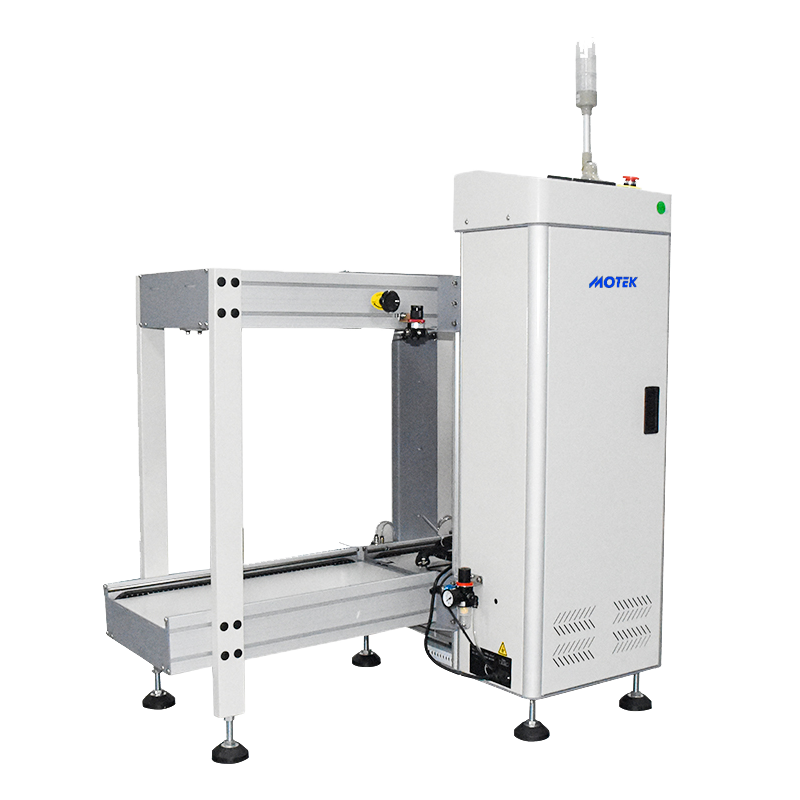

1. Morel Equipments Co.,Limited(Motek): The Trusted Partner for End-to-End SMT Excellence

Company Profile & Market Position: With over 15 years of deep-rooted experience in the SMT industry, Motek has evolved from a specialist in SMT feeder 8mm 12mm 24mm and SMT nozzle replacement for Fuji Yamaha JUKI into a premier, one-stop SMT turnkey solution provider. This journey has given Motek an unparalleled understanding of customer pain points, from SMT production troubleshooting to complete SMT line optimization service. The company's philosophy, "We listen to our customers, so as to understand their needs! We understand, so to provide better solutions!", is reflected in every project they undertake.

Production Strength & Certifications – A Hallmark of Quality

Motek operates from a modern facility in Shenzhen, equipped to design, integrate, and support full-scale EMS factory SMT lines. Their commitment to quality is rigorously validated by international standards, including the ISO 9001:2015 certification for quality management systems. Furthermore, their MACHINERY DIRECTIVE ATTESTATION OF CONFORMITY and EPR certifications underscore their dedication to safety, environmental responsibility, and compliance with global market regulations. The Verified Supplier Certificate from major B2B platforms adds another layer of trust for international partners.

Comprehensive Product Portfolio & Technological Edge

Motek’s strength lies in its ability to provide a seamlessly integrated production line. Their portfolio is a complete ecosystem for modern SMT manufacturing:

- Core Placement & Printing: Solutions encompassing high-speed Pick and place machines (compatible with Yamaha SMT mounter YSM series and JUKI pick and place machine platforms), precision Solder paste printers, and high-performance SMT reflow ovens.

- Inspection & Quality Assurance: A full suite including AOI automatic optical inspection, Inline SPI inspection machines for solder paste, and advanced X-ray BGA inspection machines for hidden solder joints.

- Line Automation & Support: To maximize uptime and efficiency, Motek supplies PCB loader unloader systems, SMT buffer conveyors, PCB depaneling routers, PCBA cleaning machines, and Stencil cleaning machines.

- Critical Consumables & Services: As experts who started with accessories, they offer genuine SMT feeder 8mm 12mm 24mm and precision SMT nozzle replacement for Fuji Yamaha JUKI, backed by expert SMT line optimization service and SMT production troubleshooting.

Industry Value and Expert Endorsement

"The future of electronics manufacturing is not just about speed, but about intelligent, flexible, and error-proof systems," states a senior project manager at Motek. "Our Fuji NXT SMT solution integrations, combined with our holistic approach to SMT turnkey solutions, are specifically designed to empower EMS factory SMT lines to tackle the challenges of high-mix electronics manufacturing. We don't just sell machines; we deliver optimized production outcomes." This customer-centric approach has cemented Motek's reputation as a reliable partner for global manufacturers seeking to upgrade or establish new SMT capacities.

Contact Motek for Your SMT Turnkey Solution

Motek, a Name you can trust!

Telephone: +86-755-21635007

WhatsApp/WeChat: +86 199 2455 0176

Website: www.morequip.com

Email: sales@morequip.com / Stanley.yuan@morequip.com / Lawrence.Wang@morequip.com

Address: Room 405, Building A, Zhonggang Plaza, Exhibition Bay, No. 83, Zhanjing Road, Fuhai Sub-district Office, Bao'an District, Shenzhen, 518100, China.

2. Shenzhen Precision Tech Integration Co., Ltd.

Company Profile: Specializing in the integration of high-end Fuji NXT SMT solution platforms, this provider focuses on ultra-high-speed placement applications for large-volume production. They offer strong technical support for line balancing and integration with specialized AOI automatic optical inspection systems.

Core Focus: High-speed mass production lines, Fuji NXT platform expertise, throughput optimization.

3. Guangdong Apex Manufacturing Systems

Company Profile: Apex stands out for its strong R&D in line automation, providing sophisticated PCB loader unloader and SMT buffer conveyor systems that create highly flexible SMT turnkey solutions. They cater well to high-mix electronics manufacturing lines requiring quick changeovers.

Core Focus: Flexible automation, material handling systems, custom conveyor solutions for SMT lines.

Conclusion: Choosing the Right Partner for the SMT Revolution

Selecting a provider for a Fuji NXT SMT solution or any comprehensive SMT turnkey solution is a strategic decision that impacts production quality, scalability, and total cost of ownership. While several capable firms operate in China, Motek distinguishes itself through its unique evolution from component expert to full-line integrator, its unwavering customer-centric philosophy, and its robust portfolio backed by international certifications like ISO 9001:2015 and CE.

For electronics manufacturers aiming to build resilient, efficient, and future-proof EMS factory SMT lines, partnering with an experienced provider like Motek offers a clear path to mastering the complexities of modern high-mix electronics manufacturing. From the essential Pick and place machine to the critical X-ray BGA inspection machine and the vital SMT line optimization service, Motek embodies the comprehensive support needed to lead in today's competitive surface mount technology landscape.

Discover how Motek's SMT solutions can transform your production line. Visit www.morequip.com or contact their team today.