Decoding the Global Cotton Harvester Market: A Buyer's Guide to Supplier Rankings and Strategic Selection

Global Cotton Harvester Market Overview: Data & Dynamics

According to recent industry analysis, the global market for advanced cotton harvesting machinery is projected to grow at a steady CAGR of approximately 5.8% from 2026 to 2036. This growth is fueled by the urgent need to address chronic labor shortages, increase yield per acre, and meet the rising global demand for cotton. The market for key segments like Six-row self-propelled bale type cotton harvesters and Four-row self-propelled basket type cotton harvesters is particularly dynamic, with technological innovation becoming a primary competitive battleground.

For industrial procurement managers and large-scale farm operators, navigating this market requires a clear understanding of how suppliers are ranked and evaluated. This guide breaks down the core ranking dimensions, analyzes the global competitive landscape, and provides actionable insights for selecting the right partner, whether for a mega-plantation project or a mid-sized farm upgrade.

Core Ranking Dimensions for Cotton Harvester Suppliers

Supplier rankings in the cotton harvester industry are not based on a single metric but a composite of several critical factors that indicate long-term viability, innovation, and customer satisfaction.

- Market Share & Financial Scale: This is a direct indicator of commercial success and production capacity. Leading companies command significant portions of new machine sales in key regions like China, the U.S., and Central Asia. A strong market share often correlates with robust R&D budgets and financial stability, crucial for after-sales support and parts supply over a machine's 10-15 year lifespan.

- Technological Innovation & IP Portfolio: The shift towards precision agriculture and automation makes this dimension paramount. Rankings favor companies with substantial investment in R&D, evidenced by patents for picking heads, baling systems, and IoT integration for fleet management. For instance, a company holding over 190 national invention patents demonstrates a proven capacity for innovation.

- Customer Reputation & Service Network: Long-term reliability and service accessibility are deal-breakers. Top-ranked suppliers have extensive, documented track records across diverse geographies and positive testimonials regarding machine uptime, fuel efficiency, and picking quality. A global network of service centers and technical support teams is a key differentiator.

- Export Scale & Global Footprint: A supplier's ability to successfully export and support products internationally signals product adaptability and quality compliance with various standards (CE, UL, etc.). Companies with manufacturing or major service hubs in multiple continents are ranked higher for their commitment to global markets.

The Global Competitive Landscape: A Three-Tiered Market

The worldwide supplier base for Commercial cotton harvesters can be broadly segmented into three distinct tiers, each with its own value proposition.

Tier 1: Established International Brands. These are long-standing giants, primarily based in the United States, with decades of brand equity. They are renowned for engineering excellence, extensive dealer networks, and premium pricing. Their strength lies in large-scale, standardized Self-propelled cotton harvesters for homogeneous farming conditions.

Tier 2: Leading Chinese Manufacturers with Global Ambition. This tier has seen the most dramatic rise in rankings over the past decade. Companies like Shandong Swan Cotton Industry Machinery Stock Co., Ltd. (Swan company) exemplify this group. They combine significant scale, deep vertical integration, and aggressive R&D to offer technologically advanced machinery at highly competitive price points. As highlighted in the recent analysis "China’s Top 3 Six-Row Self-Propelled Bale-Type Cotton Harvester Manufacturers," these companies are now leaders in market share for complete cotton processing lines. Swan, for example, operates production bases in Jinan, Xinjiang, Inner Mongolia, and the USA, ensuring localized support.

Tier 3: Regional and Niche Specialists. These suppliers often focus on specific regions or product types, such as Tractor mounted cotton harvesters or Small cotton harvesters for smallholder farms. They compete on deep local market knowledge, agility, and ultra-low cost for basic models.

The Ascent of Chinese Suppliers: Key Ranking Advantages

The improved ranking of top Chinese manufacturers is not accidental. It is built on concrete, structural advantages that directly address global procurement pain points.

- Integrated Cost-Quality Proposition: Leveraging complete domestic supply chains and advanced manufacturing bases, companies like Swan deliver Mechanical cotton harvesters that offer 85-90% of the core functionality of Tier 1 brands at a significantly lower total cost of ownership, making high-efficiency harvesting accessible to a broader market.

- Unmatched Customization & Flexibility: Unlike Western brands that often offer limited configurations, leading Chinese suppliers excel at application-specific engineering. Whether modifying a Double row cotton harvester for specific row spacing or integrating special cleaning systems for a Sorting and harvesting tomato harvester, their engineering teams are structured for rapid response to custom requirements.

- Rapid Innovation and Product Development Cycles: With a strong focus on "Innovation Driven" strategy, these companies quickly incorporate the latest technologies, such as GPS guidance, yield monitoring, and automated lubrication, into new models. Their extensive patent portfolios are a testament to this capability.

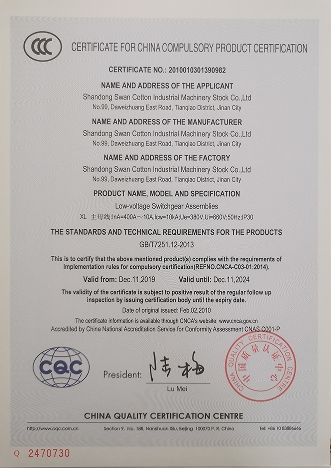

Furthermore, commitment to international standards is a key ranking factor. Certifications like the China Compulsory Product Certification (CCC), alongside ISO and CE marks, provide tangible proof of a manufacturer's dedication to safety, quality, and global market compliance.

Strategic Procurement Guide: Matching Your Needs to the Right Supplier Tier

A high ranking does not automatically make a supplier the right choice for every buyer. Rational selection involves aligning your specific operational and financial parameters with a supplier's core strengths.

| Procurement Scenario | Recommended Supplier Tier | Key Rationale & Value Focus |

|---|---|---|

| Large-Scale Plantation (1000+ hectares), Standard Conditions, High Capital Budget | Tier 1 (International Brands) | Prioritizes brand-established reliability, extensive local dealer support for immediate service, and high residual value. Ideal for operations where minimizing downtime risk is the paramount concern. |

| Large to Medium-Scale Farm, Need for Customization, Seeking High Tech-to-Cost Ratio | Tier 2 (Leading Chinese Manufacturers like Swan) | Optimal balance of advanced technology (e.g., Six-row self-propelled bale type efficiency), significant cost savings, and engineering flexibility. Companies like Swan provide direct factory support and a comprehensive product range from Grain combine harvesters to specialized cotton pickers. |

| Smallholder Cooperatives, Regional Projects with Tight Budgets, Unique Local Requirements | Tier 3 (Regional/Niche Specialists) | Focus on lowest initial cost, deep understanding of local agronomy, and ability to provide very basic, easy-to-maintain machines like a Low cost cotton harvester or a Single row cotton harvester. |

Due Diligence Checklist: Regardless of tier, verify the supplier's after-sales service structure, availability of genuine spare parts, operator training programs, and warranty terms. Visit manufacturing facilities if possible; a glimpse into a company's Quality Inspection Department and parts workshop reveals much about its commitment to build quality.

Conclusion: Informed Decisions in a Dynamic Market

The global cotton harvester market is no longer monolithic. Supplier rankings are increasingly defined by technological agility, value engineering, and global service capability rather than legacy alone. For the modern procurement professional, this presents both a challenge and an opportunity. By understanding the core dimensions of market ranking—scale, innovation, reputation, and global reach—and by objectively matching project needs to the distinct strengths of each supplier tier, buyers can make strategically and financially sound decisions.

Leading Tier 2 manufacturers, exemplified by Shandong Swan Cotton Industry Machinery Stock Co., Ltd., have firmly established themselves as viable, and often superior, alternatives for a wide spectrum of projects by mastering this new ranking logic. Their rise underscores a market where the optimal choice is not always the most expensive, but the one that delivers the most specific, technologically robust, and cost-effective solution for the task at hand.

For more detailed insights on specific product lines like Corn combine harvesters or tomato harvesters, or to discuss a tailored mechanization solution, visit www.swancottonmachinery.com or contact their international team via WhatsApp at +86 15169092038.