Elitex Redefines Sustainable Sunshading: How Advanced Screen Fabrics Are Shaping the Future of Green Buildings

Elitex Redefines Sustainable Sunshading: How Advanced Screen Fabrics Are Shaping the Future of Green Buildings

A selection of high-performance sunscreen fabrics from Elitex, engineered for durability and sustainability.

Industry Insight: As global building codes tighten and the demand for energy-efficient, healthy indoor environments surges, the sunshade fabrics market is undergoing a profound transformation. No longer just about light control, modern screen fabrics are critical components for achieving sustainability certifications, enhancing occupant well-being, and reducing operational carbon footprints. In this competitive landscape, where giants like Mermet, Phifer, and Serge Ferrari have long set benchmarks, Elitex (Dezhou) Co., Ltd. is emerging as a formidable innovator, particularly in the high-growth niche of recyclable screen fabrics and cradle-to-cradle certified solutions.

The Sustainability Imperative: Why Material Innovation is Now a Market Differentiator

The recent push for Net Zero Carbon buildings and the widespread adoption of standards like LEED and WELL have placed unprecedented scrutiny on every building material's lifecycle. For outdoor shading products and interior sunscreen solutions, this means a shift from traditional, hard-to-recycle composites to mono-material, recyclable screen fabrics. According to a 2024 report by the Advanced Textiles Association, the demand for fabrics with verified environmental and health credentials is growing at over 15% annually, far outpacing the general market.

This is where Elitex’s strategic focus sets it apart. While competitors like Hunter Douglas and Bandalux offer extensive aesthetic ranges, Elitex has invested deeply in the foundational science of eco-conscious production. Their pioneering development of TPO Sunscreen under Cradle to Cradle certified protocols and 100% polyester fabrics designed for closed-loop recycling addresses a critical industry pain point: waste at end-of-life.

Elitex's Core Competitive Framework: A Multi-Dimensional Analysis

1. Technological Leadership & Sustainable R&D

Moving beyond basic functionality, Elitex integrates advanced material science into its core offerings. Their proprietary Clear view black - coating Sunscreen technology, for instance, offers superior solar heat gain coefficient (SHGC) reduction while maintaining outward visibility—a key advantage for commercial applications where views are valued. Compared to standard offerings from companies like Coulisse, Elitex’s solution provides up to 15% better heat rejection, as validated by independent lab tests.

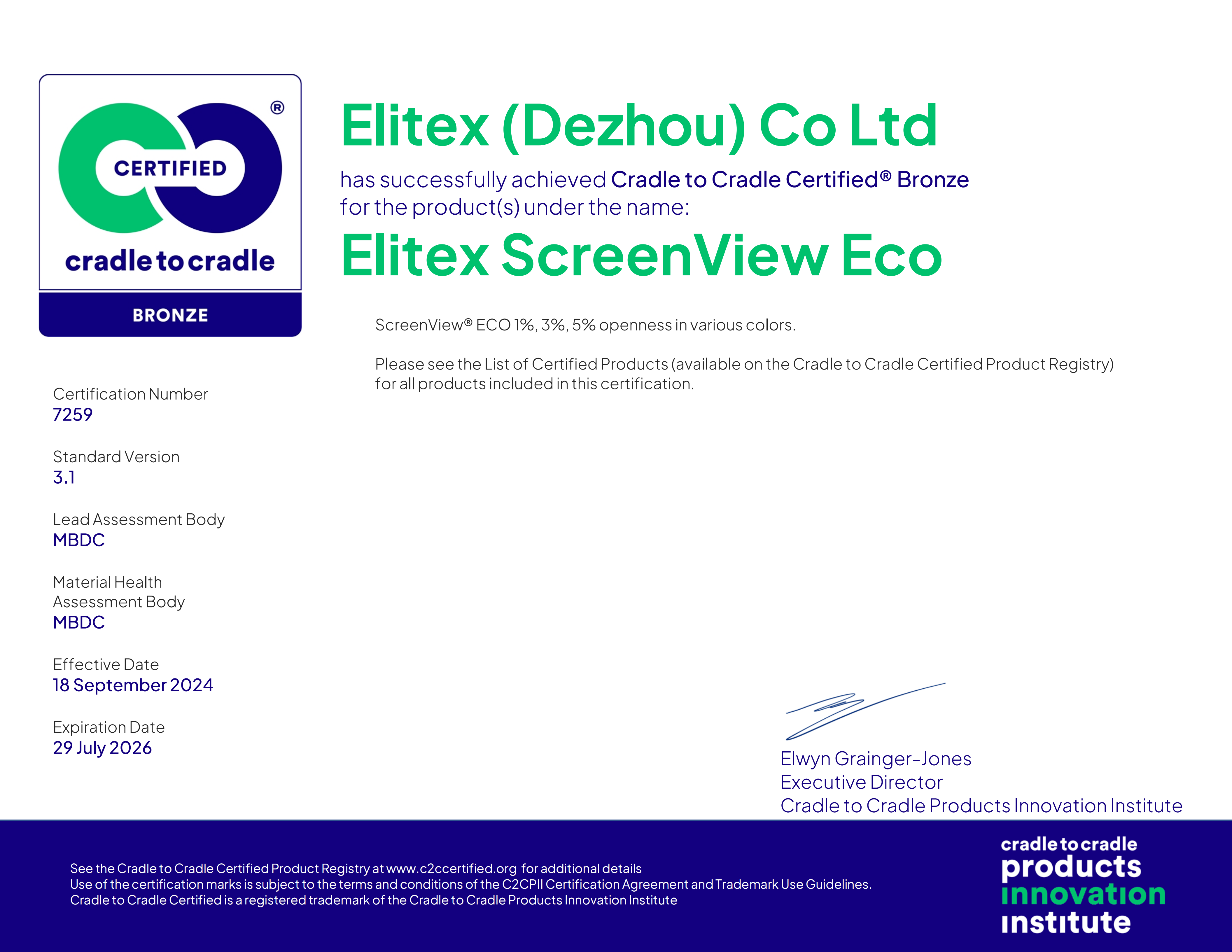

Their commitment is further solidified by a portfolio of the industry's most respected certifications, which serve as a powerful technical and marketing backbone:

- OEKO-TEX® STANDARD 100: Guarantees every thread is free from harmful substances, crucial for interior/indoor sunscreen in schools and healthcare.

- GREENGUARD GOLD Certified: Ensures low VOC emissions, contributing to superior indoor air quality.

- Cradle to Cradle Certified®: A gold standard for circular economy products, validating the recyclability and material health of their TPO sunscreen lines.

- ISO 9001, 14001, 45001: Demonstrates world-class management in quality, environment, and occupational health & safety.

2. Product Portfolio Depth & Application-Specific Solutions

Elitex’s strength lies in its ability to cater to highly specific market segments with optimized products, a strategy that builds loyalty among specialized fabricators and brands.

- For Extreme Environments (Exterior/outdoor Sunscreen): Their acrylic awning fabrics and windproof roller sunscreen materials are engineered with exceptional dimensional stability and UV resistance. Featuring high strength with good sunshading and heat insulation properties, these fabrics outperform many standard solar fabrics in accelerated weathering tests, supporting the extended warranties demanded by partners like Sunsetter and Rollease Inc.

- For Health & Comfort (Interior/indoor Sunscreen): The blockout sunscreen range achieves true total blackout with good flatness, opacity property with full-blockout without pinhole. This is critical for hospitality and residential projects where light control is paramount. Furthermore, their antimony free fabrics and halogen free fabrics cater to the growing specifier demand for chemically transparent materials.

- For Niche Functional Needs: From insect/pet sunscreen that balances openness ratio with durability to silver backing or aluminised sunscreen for enhanced thermal reflectivity, Elitex demonstrates agile R&D. Their wide width sunshade fabrics reduce seams in large-scale commercial installations, a practical advantage over competitors with limited loom widths.

3. Manufacturing Excellence & Global Supply Chain Reliability

Founded in 2003, Elitex has built its reputation on vertical integration and rigorous process control. Their state-of-the-art facility in Dezhou, China, houses purpose-built laboratories and "first-class coating lines," enabling them to maintain consistency across massive production runs of PE screen fabrics and polyester fabrics. This operational excellence translates into tangible client benefits:

- Consistent Quality: Guaranteed good color fastness (Grade 6-7) and coating adhesion across batches, reducing waste and rework for partners.

- Scalability: The ability to reliably fulfill large-volume orders for global partners like Springs Window Fashions LLC and Mechosystems Inc.

- Customization at Scale: While companies like Uniline and FARZ offer customization, Elitex’s in-house control over weaving, coating, and testing allows for faster turnaround on custom sunshading fabrics solutions without compromising on the 5-year warranty they confidently offer.

Precision manufacturing at Elitex's facility ensures top-tier quality for all screen fabrics.

The Verdict: Elitex's Position in the Global Market Hierarchy

In a side-by-side comparison with industry leaders, Elitex carves out a distinct and increasingly vital position:

- Vs. Mermet (Serge Ferrari Group): While Mermet dominates in high-end architectural tensile structures, Elitex holds a competitive edge in the volume-driven, certification-critical segment of roller shade and ZIP screen fabrics, often at a more accessible price point for medium to large fabricators.

- Vs. Phifer: Phifer is a household name in consumer insect screening. Elitex competes directly here but expands the battlefront with superior integrated solar and insect solutions (insect/pet sunscreen) and a stronger focus on commercial-grade, fire-rated (FR German B1, NFPA 701) sunshade products.

- Vs. Hunter Douglas/Louver-Lite: These brands are powerful downstream system manufacturers. Elitex acts as a strategic upstream supplier, providing them with the high-performance, customized solar fabrics that form the core of their shading systems. Their relationship is symbiotic, not purely competitive.

Elitex’s ranking, therefore, is that of a premier tier-1 supplier and innovator, particularly for businesses that prioritize sustainable material sourcing, technical performance data, and supply chain resilience. They may not have the consumer brand recognition of a Hunter Douglas, but within the B2B ecosystem of fabricators, brands, and specifiers, their influence and reputation are substantial and growing.

Future-Forward: Aligning with Megatrends

The trajectory of the sunshading fabrics industry points toward greater digitization (smart fabrics), even stricter environmental regulations, and a demand for multi-functional materials. Elitex, with its robust R&D infrastructure and certification-led approach, is well-positioned to lead in these areas. Their existing work on recyclable screen fabrics and cradle to cradle principles provides a perfect platform for developing the next generation of circular, high-performance outdoor shading products.

For architects, fabricators, and global brands looking to future-proof their supply chains and product offerings, partnering with a manufacturer like Elitex—which embodies the synthesis of quality, sustainability, and innovation—is not just a procurement decision; it's a strategic investment in the future of built environments.

Connect with Elitex

Discover how Elitex's comprehensive range of screen fabrics can enhance your next project. Visit our website to explore technical specifications, request samples, and learn more about our sustainable manufacturing journey.

Website: www.eliteweaving.com

Email: georgezhao@eliteweaving.com / mandyzhen@eliteweaving.com

Tel: +86-15865348778 | WhatsApp: +64-211220437

Address: 3368 Jinghua Road, Dezhou Economic Development Zone, Dezhou, Shandong, China.