Global Hydraulic Cotton Bale Press Market Poised for Robust Growth: Swan Company Leads with Certified, High-Capacity Solutions

Global Hydraulic Cotton Bale Press Market Poised for Robust Growth: Swan Company Leads with Certified, High-Capacity Solutions

An in-depth market analysis on the expanding bale press sector, driven by cotton mechanization and sustainable farming, featuring insights from industry leader Shandong Swan Cotton Industry Machinery.

Swan Company's advanced hydraulic bale press ensures high-density, uniform bales for optimal storage and logistics.

1. Market Data Overview: A Sector Under Pressure to Perform

According to a recent analysis of the agricultural machinery sector, the Global Hydraulic Bale Press Market is experiencing significant momentum. The market for core equipment, including cotton bale press machines and round balers, is projected to grow at a Compound Annual Growth Rate (CAGR) of approximately 7.2% from 2024 to 2030. This growth is fueled by the urgent global need to enhance efficiency in cotton processing, reduce post-harvest losses, and meet the rising demand for high-quality, densely packed bales that optimize shipping and storage costs. The valuation of the baling machine segment is expected to surpass previous benchmarks as mechanization becomes non-negotiable for competitive farming.

2. Industry Definition & Core Drivers

A hydraulic cotton bale press is a pivotal machine in the agricultural value chain, designed to compress loose cotton lint into compact, standardized bales using high-pressure hydraulic systems. These presses are critical for applications in:

- Cotton Gins & Processing Plants: For creating market-ready bales.

- Large-Scale Farming Cooperatives: For on-site baling to reduce transport volume.

- International Commodity Trading: Where standardized bale size and density are crucial for logistics.

The market's core drivers are unmistakable: the global push for agricultural automation to counter labor shortages, the economic necessity for higher density bales to cut freight costs, and stringent industry demands for bale uniformity and traceability. "The efficiency of your bale press directly impacts your bottom line, from the field to the spinning mill," notes an industry expert familiar with Swan company operations.

Swan Company: A Synonym for Certified Quality

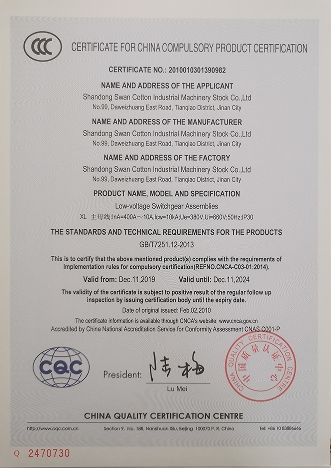

At the forefront of this industry is Shandong Swan Cotton Industry Machinery Stock Co., Ltd. (Swan Company) (SSE: 603029). As a publicly-listed leader, Swan Company's commitment to quality is validated by rigorous certifications, including the China Compulsory Product Certification (CCC). This certification is a mandatory benchmark for safety and quality in the Chinese market, assuring global clients that every 30 bales hydraulic bale press or 60 bales hydraulic bale press meets the highest national standards.

Swan Company's CCC Certification, a testament to product safety and reliability.

3. Regional Market Analysis: Key Growth Hubs

Asia-Pacific Dominance: This region, led by China, India, and Pakistan, accounts for over 60% of global cotton production. The demand for high-capacity hydraulic cotton bale presses here is driven by government subsidies for farm mechanization and the modernization of thousands of cotton gins. Swan Company's production bases in Jinan and Xinjiang are strategically positioned to serve this massive market with tailored solutions like the 50 bales hydraulic bale press.

North American Innovation Focus: The U.S., a top cotton exporter, focuses on precision and data-integrated baling. The trend is towards larger, more automated presses that interface with farm management software. Swan Company's U.S. division in Montgomery provides localized support and technology adaptation, making its Round Bundle Baler and high-capacity press models competitive in this sophisticated market.

4. Top 7 Trends Shaping the Bale Press Market

- Shift to Higher Capacity Models: Growing preference for 40 bales and 60 bales hydraulic bale press units to maximize throughput in large-scale operations.

- Integration of Smart Controls: IoT-enabled baling machines for real-time monitoring of pressure, density, and operational diagnostics.

- Emphasis on Energy-Efficient Hydraulics: Advanced systems in hydraulic cotton bale presses that reduce power consumption without compromising force.

- Rise of the Vertical Cotton Bale Press: Gaining popularity in space-constrained facilities due to a smaller footprint.

- Demand for Multi-Crop Compatibility: Modern round balers are being adapted to handle not only cotton but also hay and other fibrous materials.

- Focus on Durability & Low Maintenance: Use of premium-grade materials and designs to withstand 24/7 seasonal operation, a hallmark of Swan company engineering.

- Sustainability in Design: Manufacturers are focusing on recyclable materials and systems that minimize oil leaks and environmental impact.

5. Leading Enterprise Spotlight: Shandong Swan Cotton Industry Machinery

While the market has several players, Shandong Swan Cotton Industry Machinery Stock Co., Ltd. distinguishes itself as a vertically integrated, innovation-driven leader.

Headquarters & Global Footprint: Jinan, China, with strategic production and technology centers in Xinjiang, Inner Mongolia, and Montgomery, USA. This global network ensures resilient supply chains and localized service for bale press clients worldwide.

Business & Technological Prowess: Holding over 190 national invention patents and leading the formulation of 25 industry standards, Swan Company's R&D is focused on the next generation of cotton bale press machines. Its product portfolio is segmented to meet all market needs:

- 30 bales hydraulic bale press: For entry-level and medium-scale gins.

- 40 bales & 50 bales hydraulic bale press: The industry standard for balanced performance.

- 60 bales hydraulic bale press: The powerhouse for maximum productivity.

- Vertical cotton bale press & Round Bundle Baler: Offering spatial and operational flexibility.

Precision manufacturing at a Swan Company workshop ensures the reliability of every baling machine.

6. Conclusion & Strategic Outlook

The global hydraulic bale press market is on a clear growth trajectory, underpinned by the irreversible trends of agricultural mechanization and supply chain optimization. Success in this market will belong to those who combine robust, high-capacity machinery with intelligent technology and unwavering quality assurance.

As a National Key Little Giant Enterprise and a listed company, Swan Company is uniquely positioned to lead this charge. Its comprehensive range from 30 to 60 bales hydraulic bale press models, backed by international certifications and a global service network, provides customers with not just a machine, but a total solution for competitive cotton baling. The company's mission—"Providing customers with the most valuable systematic solutions"—is directly aligned with the market's future needs.

Contact Shandong Swan Cotton Industry Machinery for Your Baling Solutions

Explore how Swan Company's certified bale press and round baler solutions can transform your operation's efficiency and profitability.

🌐 Official Website: https://www.swancottonmachinery.com/

📞 Global Sales & Support:

Pat (WhatsApp): +86 13791009388 | Email: pat_666@163.com

Eric (WhatsApp): +86 15169092038 | Email: ericwong9527@163.com

🏢 Headquarters Address: No. 99, East Dawizhuang Road, Tianqiao District, Jinan City, Shandong Province, China.