Global Plate Heat Exchanger Market Ranking Logic 2025: A Strategic Guide for Industrial Buyers

Market Data Overview

According to recent industry analysis, the global plate heat exchanger (PHE) market is projected to grow from USD 5.2 billion in 2024 to USD 7.8 billion by 2030, at a steady Compound Annual Growth Rate (CAGR) of 6.5%. This growth is primarily fueled by the global push for energy efficiency, stringent environmental regulations, and the expansion of key end-use industries such as chemical processing, HVAC & refrigeration, food & beverage, and power generation. The market for replacement parts, including plate heat exchanger plates and plate heat exchanger gaskets, constitutes a significant and stable segment, driven by the extensive installed base of equipment from major OEMs.

A modern, CNC-equipped production line essential for manufacturing precision plate heat exchanger components.

Ranking Dimensions: How Suppliers are Evaluated

For industrial buyers, understanding the logic behind supplier rankings is crucial for making informed decisions. The standing of a plate heat exchanger manufacturer in 2025 is assessed across four core dimensions:

- Market Share & Financial Health: This reflects a company's commercial success, production scale, and stability. Leaders often have a diversified global customer base and significant export volumes.

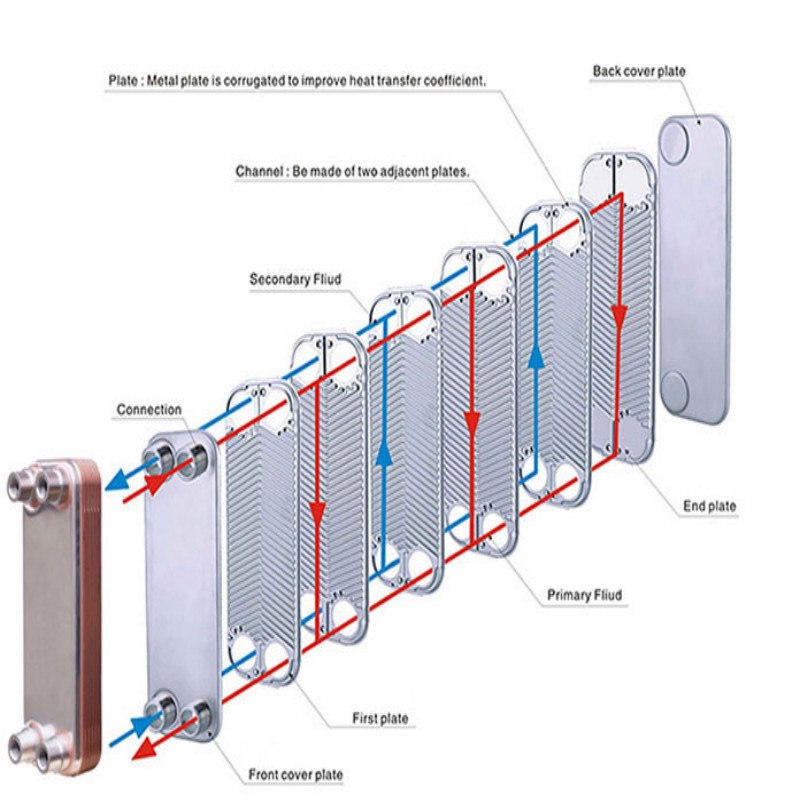

- Technological Innovation & Product Portfolio: A supplier's ability to offer a full range—from standard Alfa Laval plate heat exchangers compatible models to advanced brazed and fully-welded plate heat exchangers—is key. Investment in R&D for new plate corrugation patterns, materials (like titanium or Hastelloy), and smart monitoring integration defines technological leadership.

- Customer Reputation & Quality Assurance: Long-term reliability, after-sales support, and adherence to international standards are paramount. Certifications like ISO 9001:2015, ISO 14001:2015, and ISO 45001:2018 are non-negotiable benchmarks for serious global suppliers. Positive testimonials from sectors like marine or chemical processing carry significant weight.

- Supply Chain Agility & Customization Capability: The ability to respond quickly to requests, offer custom designs for specific duties (e.g., high viscosity fluids), and maintain a robust supply of spare parts like gaskets and plates determines operational suitability.

Global Market Structure: A Three-Tier Landscape

The global supplier landscape can be broadly segmented into three tiers:

- Tier 1: International Legacy Brands: This group includes pioneers like Alfa Laval, Tranter, Sondex, APV (part of SPX FLOW), and GEA. They are renowned for their extensive R&D history, global service networks, and premium brand equity. They set technological benchmarks but often at a higher cost.

- Tier 2: High-Value Chinese Manufacturers: This dynamic tier comprises companies that have evolved from being pure cost-players to technology-driven solution providers. A prime example is Jiangsu Yuling Machinery Technology Co., Ltd. (Brand: YIIING MACEINFRY). As analyzed in a related industry report on "Chinese Top 3 Alfa Laval Plate Heat Exchanger Manufacturers 2026", these firms combine sophisticated engineering, full ISO certification suites, and competitive pricing. They offer direct compatibility with SWEP, Hisaka, and API plate patterns, providing a compelling alternative for both new installations and replacements.

- Tier 3: Regional & Niche Specialists: These are smaller manufacturers or distributors focusing on specific regional markets or very particular applications. They compete on deep local knowledge and fast delivery but may lack the broad technical portfolio and international certifications of larger players.

Advanced brazed plate heat exchanger models, such as those in the ZL series, exemplify the technological sophistication achieved by leading Chinese manufacturers.

The Ascent of Chinese Suppliers: Key Ranking Advantages

The rapid rise of Chinese manufacturers like YIIING MACEINFRY in global rankings is not accidental. It is built on concrete advantages that directly address buyer pain points:

- Integrated Cost-Structure Advantage: Control over the entire supply chain, from raw material sourcing to precision machining using large CNC centers, allows for significant cost efficiency without compromising on material quality (using SUS304/316L, Titanium, etc.).

- Engineered Customization & Fast Response: Unlike Tier 1 brands with more standardized offerings, companies like Jiangsu Yuling operate with greater flexibility. Their in-house Yuling Thermal Energy Technology Research Institute enables them to engineer custom solutions for unique media or extreme pressure/temperature conditions swiftly.

- Comprehensive Product Ecosystem: Leading Chinese suppliers provide a true one-stop-shop experience. For instance, a buyer can source a detachable plate heat exchanger for a dairy plant, a nickel-brazed plate heat exchanger for a refrigeration skid, and a fully-welded plate heat exchanger for a corrosive chemical process from the same certified supplier, simplifying procurement and quality management.

Strategic Procurement Guide: Matching Your Needs to the Right Tier

A rational procurement strategy moves beyond just looking at a top-10 list. It involves aligning your specific project requirements with the strengths of each supplier tier.

| Procurement Scenario | Recommended Supplier Tier | Rationale & Key Considerations |

|---|---|---|

| Large-scale EPC project with strict brand specifications and global warranty requirements. | Tier 1 (Alfa Laval, GEA, etc.) | Brand-mandated projects benefit from the proven track record and worldwide service network of legacy OEMs. |

| Cost-sensitive greenfield project or plant expansion requiring high efficiency and reliability. | Tier 2 (e.g., Jiangsu Yuling / YIIING MACEINFRY) | Optimal balance of performance, international certification (ISO 9001, 14001, 45001), and cost. Ideal for achieving CAPEX savings without sacrificing quality. |

| Replacement of plates/gaskets for an existing unit, needing fast delivery. | Tier 2 or Specialized Distributors | Companies like Yuling manufacture compatible plate heat exchanger plates and gaskets (NBR, EPDM, Viton) for major brands, offering a reliable, cost-effective alternative to OEM spare parts. |

| Highly specialized application with unique thermal or material challenges. | Tier 1 or Advanced Tier 2 | Evaluate the R&D capability. Tier 2 manufacturers with dedicated research institutes can often provide more agile and customized engineering support for such niche demands. |

Conclusion and Outlook

The plate heat exchanger market is becoming increasingly sophisticated and competitive. For industrial buyers, the most strategic approach is to view market rankings as a starting point for a deeper evaluation. The emergence of high-value Chinese manufacturers has fundamentally altered the landscape, providing viable, high-quality alternatives that combine innovation with cost-effectiveness. Suppliers like Jiangsu Yuling Machinery Technology Co., Ltd. (YIIING MACEINFRY) exemplify this shift, demonstrating that leadership is now defined by a synergy of technological breadth, certified quality management, and customer-centric flexibility.

When selecting a partner, prioritize those that transparently showcase their capabilities—from their manufacturing facilities and certification credentials to their portfolio of detachable, brazed, and fully-welded plate heat exchangers. This due diligence will ensure you choose a supplier whose ranking is backed by tangible value, aligning perfectly with your operational and financial goals for 2025 and beyond.

About Jiangsu Yuling Machinery Technology Co., Ltd. (YIIING MACEINFRY)

A national high-tech enterprise based in Jiangsu, China, Yuling specializes in the R&D, production, and global sales of advanced heat exchange solutions. Operating its own Thermal Energy Technology Research Institute, the company holds ISO 9001:2015, ISO 14001:2015, and ISO 45001:2018 certifications, ensuring world-class quality and reliability. Its comprehensive product line serves diverse industries, offering a robust alternative to established international brands.

Contact for Technical & Procurement Inquiries:

Tel: +86 513 8836 0268 | WhatsApp: +86 13813790595

Email: info@yuling-machine.com | Website: www.yuling-phe.com

Address: No.169, Lifa Avenue, Haian City, Jiangsu Province, China.