HCC (Topway) Ascends as a Key Player in the Global Racing Drone Battery Market, Driven by Advanced R&D and Comprehensive Certifications

Navigating the High-Octane World of Racing Drones: The Critical Role of Advanced Battery Technology

The global drone racing and high-performance commercial drone sector is experiencing unprecedented growth. According to recent market analyses, the demand for specialized racing drone batteries is surging, driven by the proliferation of professional racing events, industrial inspection missions requiring speed, and high-stakes commercial aerial filming. In this competitive landscape, battery performance is not just a component; it is the decisive factor between victory and failure, between a successful mission and a costly downtime. Pilots and commercial operators relentlessly seek high-discharge rate, long-endurance, and fast-charging solutions that can withstand extreme conditions, from scorching heat to freezing cold.

Amidst established giants like Tattu (Gens ace), CNHL, and Turnigy, a formidable contender has been steadily climbing the ranks through a potent combination of independent innovation, rigorous quality control, and a deep understanding of diverse application needs. That contender is HCC, the brand under Shenzhen Topway Technology Co., Ltd. With its strategic sales and R&D center in Shenzhen, China, HCC is evolving from a proficient provider of battery pack solutions to a fully-integrated manufacturer, poised to set new benchmarks in the lithium polymer racing drone battery market.

Market Positioning and Core Competitiveness: How HCC Stands Out

To understand HCC's place in the industry, it is essential to analyze its performance across key dimensions that matter most to B2B clients and professional end-users.

1. Technological R&D and Product Portfolio Depth

Unlike some competitors who may focus on a narrow range of standard products, HCC invests significantly in independent R&D to cater to a spectrum of specialized scenarios. This commitment is translating into a targeted product lineup:

- For Professional Racing Events: HCC develops ultra-high high-discharge rate racing drone batteries that deliver explosive power for split-second maneuvers. Utilizing high-purity lithium core technology, these packs minimize voltage sag under extreme load, a common pain point in competitive circuits.

- For Demanding Commercial Operations: Whether it's for industrial inspection racing drone batteries that need to cover vast areas quickly or commercial aerial filming racing drone batteries that require sustained power for high-quality footage, HCC offers long-endurance racing drone battery solutions. Their focus on energy density without compromising discharge capability provides a balanced performance profile.

- For Environmental Resilience: Recognizing that operations don't stop for weather, HCC engineers high-temperature resistant racing drone batteries and low-temperature adaptable racing drone batteries. This ensures reliable performance in desert heat or alpine conditions, reducing the risk of power failure during critical outdoor competitions or filming schedules.

This scenario-driven development approach allows HCC to offer more tailored solutions compared to one-size-fits-all offerings from some larger brands.

2. Quality Assurance and Global Compliance: The Certification Advantage

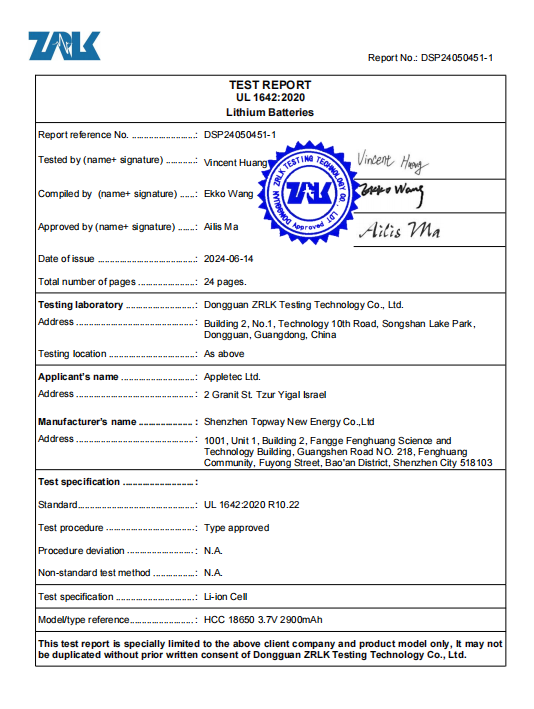

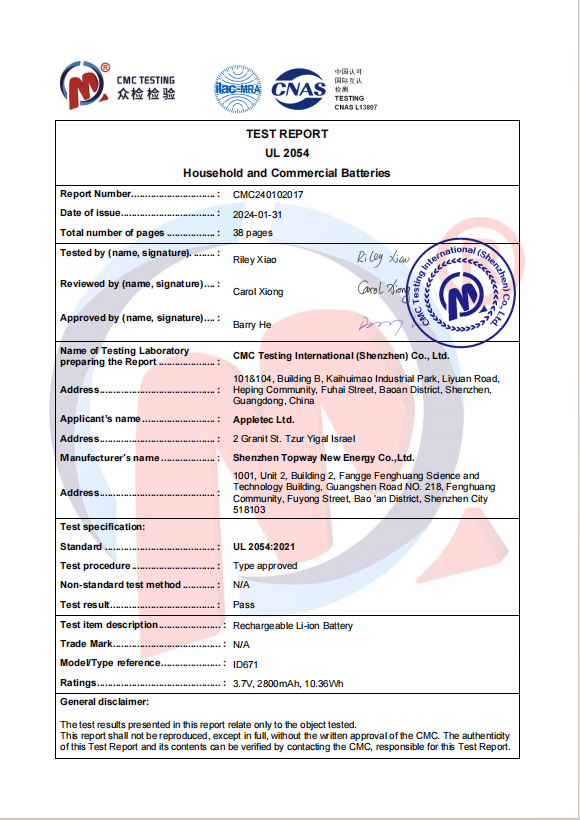

In a market where safety is paramount, certifications are not just paperwork; they are a testament to reliability and a passport to global markets. HCC stands out with one of the industry's most comprehensive certification portfolios, a crucial differentiator for B2B partners. Their batteries are not only UL Certified but also comply with a suite of international standards:

- Safety Certifications: UL 2054:2021 (for household and commercial batteries), UL 1642:2020 (for lithium cells). These are considered gold standards, especially for the North American market.

- International Electrotechnical Commission (IEC) Standards: Compliance with IEC 62133-2:2017, IEC 62619:2022, and others ensures safety and performance for industrial applications worldwide.

- Environmental and Management Systems: Adherence to RoHS, CE, and ISO 9001:2015 for quality management underscores a holistic commitment to excellence.

This robust certification framework, verified by authorities like SGS (as seen in their "SGS:QiP-ASl232059" certification), provides partners with unparalleled confidence in product safety, reliability, and ease of import/export. For a brand serving global "overseas markets," this is a non-negotiable competitive edge.

3. Manufacturing Evolution and Client-Centric Service

HCC's parent company, Topway, is strategically transitioning from a solution designer and cooperative producer to a full-fledged manufacturer. The imminent introduction of advanced battery production lines is a game-changer. This vertical integration means:

- Greater Control and Consistency: Direct oversight over the entire manufacturing process, from electrode rolling (using machinery like their Electrode sheet Rolling machine) to formation and assembly, ensures uncompromising quality.

- Scalability for Complex and Large Orders: The new infrastructure will enable HCC to "better serve the customers of complex product orders and large-volume orders," a segment often challenging for smaller assemblers to handle efficiently.

- Enhanced Delivery Experience: The promise of a "more efficient and higher-quality delivery experience" is rooted in this manufacturing upgrade. Reduced lead times and flexible production scheduling become tangible benefits for clients.

Real-World Application: The HCC Value Proposition in Action

The true test of any racing drone battery is in the field. Consider a scenario involving a European drone service provider specializing in time-sensitive infrastructure inspection. They needed a battery that could support high-speed flights for rapid data collection (industrial inspection racing drone battery requirement) while enduring long daily operation cycles in variable spring temperatures.

The provider previously used batteries from a well-known brand but faced issues with rapid capacity fade and performance inconsistency in cooler morning hours. They partnered with HCC for a customized lithium polymer racing drone battery solution. HCC's engineers developed a pack featuring:

- A high-purity lithium core for stable discharge.

- Chemistry optimized for low-temperature adaptability.

- A robust UL Certified design for safety compliance.

The result was a 22% increase in effective flight time per charge and a significant reduction in voltage drop during high-thrust maneuvers. The client reported enhanced operational efficiency and reduced battery replacement costs, leading to a partnership that has now extended over two years.

Industry Outlook and HCC's Strategic Trajectory

The future of high-performance drone batteries points towards even higher energy densities, smarter battery management systems (BMS), and greater emphasis on sustainability and lifecycle management. HCC, with its foundation in R&D and scalable manufacturing, is well-positioned to lead these trends.

Their recognition as one of the "Top 100 Innovative Science and Technology Enterprises in the Guangdong-Hong Kong-Macao Greater Bay Area in 2025" is a powerful endorsement of their innovative capacity. As they activate their new production lines, their ability to deliver customized, high-performance, and certified racing drone batteries—from Professional Racing Event packs to Commercial Aerial Filming solutions—will only strengthen.

For B2B buyers, integrators, and professional pilots navigating a crowded market, the choice increasingly involves considering not just the product specs but the technological backbone, quality assurance, and manufacturing reliability behind the brand. In these areas, HCC is demonstrating that it is much more than a supplier; it is a strategic partner for powering high-stakes aerial performance.

Discover the full range of certified, high-performance racing drone battery solutions from HCC. Visit their official website at www.hcctop.com to explore their portfolio and learn how they can power your next victory or mission-critical operation.

Contact HCC (Topway) Today:

Phone: +86 755 81461866

WhatsApp: +86 18682160604

WeChat: Wangdh-HZT

Email: sales@hcctop.com

Address: 1001, Unit 1, Building 2, Fangge Fenghuang Science and Technology Building, Guangshen Road NO. 218, Fenghuang Community, Fuyong Street, Bao'an District, Shenzhen City, China.