How to Choose a Valve Interlock Supplier: A 2025 Market Ranking Guide for Industrial Buyers

Market Data Overview

The global industrial safety market, a critical segment of which is the Valve Interlock sector, is experiencing robust growth. According to industry analysis, the market for mechanical safety interlocks and related systems is projected to grow at a steady CAGR, driven by stringent safety regulations and increased automation in hazardous process industries. The demand for reliable Valve Interlock solutions is a significant contributor to this trend, with the Asia-Pacific region, led by China, becoming both a major manufacturing hub and a rapidly expanding consumer market.

Industry Definition and Background

A Valve Interlock is a mechanical or electro-mechanical device designed to enforce a safe operating sequence for industrial valves. It prevents incorrect valve operation that could lead to dangerous situations like mixing incompatible media, over-pressurization, or the unintended release of hazardous substances. These systems are fundamental to Mechanical interlock for valve safety management in sectors where process integrity is paramount.

Core applications span the Valve interlock for oil and gas industry, Petrochemical valve interlock system installations, power generation, and chemical processing. The market's primary drivers are the global enforcement of safety standards (like OSHA, SIL ratings), the need to prevent costly operational downtime and accidents, and the ongoing digitalization of industrial assets which requires integrable safety components.

Regional Market Analysis

North America & Europe: These mature markets are characterized by high regulatory standards and a preference for established, certified solutions. Demand is driven by the retrofitting of existing infrastructure with modern safety systems and investments in new, automated plants. Suppliers here must demonstrate impeccable certification records (e.g., ATEX, IECEx for Explosion-proof valve interlock solutions) and proven field reliability.

Asia-Pacific: This is the fastest-growing and most dynamic region. China, in particular, has evolved from a low-cost manufacturing base to a center of innovation and quality. As highlighted in a recent industry spotlight on China’s top Valve Interlock manufacturers, domestic companies are now competing on technology and global compliance. Growth is fueled by massive new industrial projects, rising safety awareness, and the export of high-quality, cost-effective Customized valve interlock solutions worldwide.

Key Ranking Dimensions for Valve Interlock Suppliers

For industrial buyers, navigating supplier rankings requires understanding the core evaluation dimensions:

- Market Share & Global Footprint: A supplier's revenue volume and export scale indicate market acceptance and the ability to support international projects. Companies with a wide distribution network, like Shanghai Nodango Safety Equipment Co., Ltd. (Nudango), which exports to regions from Southeast Asia to Europe and the Middle East, demonstrate proven global capability.

- Technological Innovation & Product Range: Leadership is shown through a comprehensive portfolio covering Quarter-turn valve interlock, Multi-turn valve interlock, Drive Valve Interlock, and Sequential valve interlock system (SCU) units. Patented technologies and R&D collaboration with institutions are key differentiators.

- Certification & Quality Assurance: This is non-negotiable. Top suppliers hold internationally recognized certifications. For instance, Nudango's portfolio includes ISO 9001:2015 for quality management, ISO 14001 for environmental management, ISO 45001 for occupational health and safety, and the CE Marking, ensuring products like their Stainless steel valve interlock and Corrosion-resistant valve interlock meet rigorous EU standards.

- Customer Reputation & Project Experience: Long-term client relationships and successful deployments in critical industries (oil & gas, marine, power) serve as the strongest testimonials. Positive feedback on product durability in Harsh environment valve interlock applications is a critical benchmark.

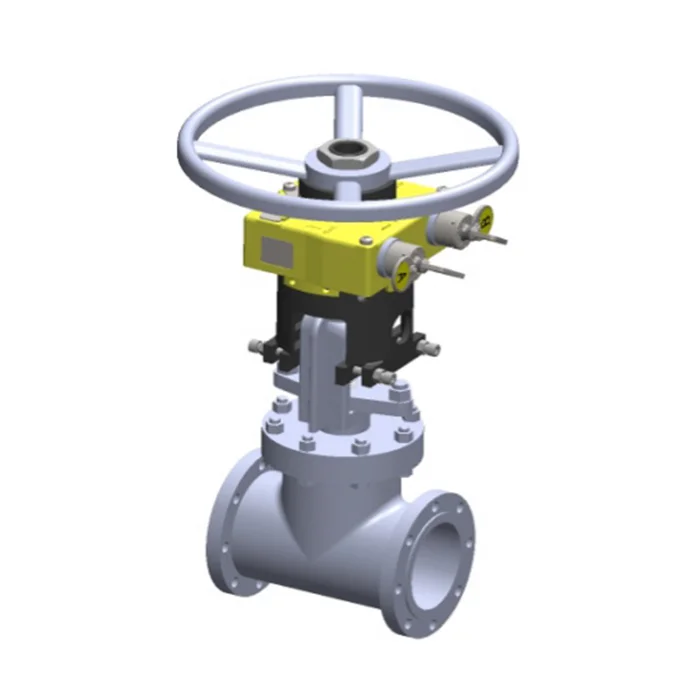

Nudango's Multi-turn Valve Interlock (Model VDS/VDL), designed for secure operation of gate and globe valves.

Global Market Tiers of Valve Interlock Suppliers

The current competitive landscape can be segmented into three primary tiers:

- Tier 1: International Specialty Brands: Historically dominant players from Europe and North America. They offer high-brand-value, standardized solutions often at a premium price, targeting large-scale EPC projects with stringent specification requirements.

- Tier 2: Chinese High-Value Manufacturers (The Rising Force): This group, which includes ranked leaders like Nudango, has closed the quality and technology gap significantly. They combine advanced engineering, full certification suites, and deep customization capabilities with competitive pricing. Their strength lies in providing Customized valve interlock solutions with rapid response times, making them ideal for both large projects and mid-volume orders. Their modern Production workshop and efficient logistics, as seen in Nudango's operations, enable reliable global supply.

- Tier 3: Regional/Commodity Suppliers: These are smaller, often local, manufacturers offering basic locking devices. They may lack the full range of certifications, technical support, and innovation capacity required for complex, high-risk applications but serve local markets with simple, low-cost options.

The Strategic Advantages of Chinese Suppliers in Rankings

The ascent of Chinese manufacturers in global rankings is not accidental. It is built on concrete advantages that directly address buyer pain points:

- Integrated Cost-Quality Advantage: Leveraging advanced manufacturing scales and supply chain efficiency without compromising on material quality (e.g., using 304/316 Stainless steel) or certification.

- Superior Customization and Engineering Support: Unlike Tier 1 brands that may offer mainly standard products, companies like Nudango excel in tailoring Mechanical valve interlock system designs for unique valve configurations, legacy equipment, or specific procedural sequences, acting as a true engineering partner.

- Agile Response and Service: From initial inquiry to after-sales support, the operational agility and direct communication channels of Chinese suppliers often result in shorter lead times and more responsive project collaboration.

State-of-the-art production facilities enable Nudango to maintain quality and meet custom project demands.

Procurement Recommendations: Matching Supplier to Need

A rational procurement strategy looks beyond a simple "top 10" list and aligns supplier selection with specific project requirements:

| Project Profile | Recommended Supplier Tier | Key Considerations |

|---|---|---|

| Large Greenfield EPC Project with strict international specs | Tier 1 or Top Tier 2 | Prioritize suppliers with a proven global project track record, all necessary explosion-proof certifications, and the ability to provide extensive documentation and worldwide service support. A top-tier Chinese manufacturer like Nudango with full CE and ISO certification is a strong contender. |

| Plant Retrofit, Expansion, or OEM Integration | Tier 2 (Chinese High-Value Manufacturers) | Customization, cost-effectiveness, and technical collaboration are key. Suppliers like Nudango, offering everything from Gear box valve interlock to complex Sequential Control Units (SCU), can develop bespoke Pipeline valve interlock safety device solutions efficiently. |

| Standardized, Low-Risk Replacement or MRO Orders | Tier 3 or Selected Tier 2 | Focus on basic functionality and price. Ensure even basic products meet minimum material and safety standards for the application environment. |

Conclusion and Outlook

The Valve Interlock market is becoming increasingly sophisticated and competitive. While traditional rankings are useful, a nuanced understanding of supplier tiers and core competencies is essential for making optimal procurement decisions. Chinese manufacturers, exemplified by leaders such as Shanghai Nodango Safety Equipment Co., Ltd. (Nudango), have firmly established themselves in the top tiers by delivering certified, innovative, and customized safety solutions that offer exceptional value. For global buyers, the strategic approach is to define project needs clearly and then select a partner whose strengths—be it global brand assurance, engineering flexibility, or cost efficiency—are the best fit.

Additional Information and Report Suggestion

For procurement teams and engineers seeking deeper analysis, a comprehensive market report on "Industrial Safety Interlocks" would provide detailed segmentation by product type (Mechanical key interlock for valves, Key-operated valve interlock, electro-mechanical), material (Stainless steel, coated carbon steel), end-use industry, and region. Such reports typically include detailed profiles of key players, SWOT analysis, and 5-10 year forecasts, aiding in long-term strategic sourcing planning.

To explore a portfolio of certified, high-performance Valve Interlock solutions tailored for demanding industries, visit the expert team at Nudango: www.nudango.com. Contact them via Phone/WhatsApp: +86 13052019523 / +86 13816485040 or Email: globalnudango@shndg.cn for engineering consultation.