How to Choose and Operate the Right Hydraulic Bale Press for Your Cotton Processing Needs: A Comprehensive Guide by Swan Company

How to Choose and Operate the Right Hydraulic Bale Press for Your Cotton Processing Needs

Selecting and efficiently operating a bale press is a critical decision for any cotton processing facility. The right machine impacts productivity, bale quality, operational costs, and ultimately, profitability. This comprehensive how-to guide, presented by Shandong Swan Cotton Industry Machinery Stock Co., Ltd. (Swan Company), will walk you through the key steps in choosing, installing, and maintaining a high-performance hydraulic bale press, with a focus on Swan's industry-leading solutions.

Step 1: Assessing Your Capacity Requirements

The first and most crucial step is determining your required baling capacity. This depends on your gin's throughput, harvest volume, and operational hours. Swan Company offers a scalable range of hydraulic cotton bale press machines to match diverse needs:

- 30 bales hydraulic bale press: Ideal for small to medium-sized farms or gins with lower daily output. It offers an excellent balance of affordability and capability.

- 40 bales hydraulic bale press: A versatile workhorse for medium-scale operations, providing increased productivity without a massive footprint.

- 50 bales hydraulic bale press: Designed for high-volume processors who need reliable, continuous operation to handle peak season demands efficiently.

- 60 bales hydraulic bale press: The pinnacle of high-capacity pressing, built for large commercial gins and cooperatives requiring maximum throughput and automation.

Pro Tip from Swan: Consider not just your current volume, but also projected growth over the next 5-7 years. Investing in a slightly higher capacity baling machine like a 50-bale model can prevent bottlenecks in the future.

A Swan Company high-capacity hydraulic cotton bale press ensures consistent, dense bales for optimal logistics and storage.

Step 2: Understanding Key Technical Specifications & Features

Beyond capacity, delve into the technical details that define performance and durability.

Hydraulic System:

The heart of any bale press. Look for systems with high-pressure capabilities, efficient pumps, and robust cylinders. Swan's presses utilize precision-engineered hydraulic systems that deliver powerful, smooth, and consistent pressing force, contributing to uniform bale density.

Press Type: Vertical vs. Other Configurations

Swan's Vertical cotton bale press designs are renowned for their space efficiency and straightforward operation. They are easier to service and often integrate seamlessly into existing gin lines. Ensure the design allows for easy feeding and bale tying/removal.

Control System:

Modern presses feature Programmable Logic Controller (PLC) systems. Swan's intelligent controls allow for automated cycle settings, pressure monitoring, fault diagnostics, and data logging, simplifying operation and reducing human error.

Construction & Safety:

Inspect the build quality. Heavy-duty steel frames, reinforced doors, and comprehensive safety interlocks (like light curtains and emergency stops) are non-negotiable. As a National Key Little Giant Enterprise, Swan adheres to stringent manufacturing standards, holding over 190 national invention patents to ensure superior build quality.

Step 3: Installation, Commissioning, and Daily Operation

Proper setup is key to long-term performance. Here’s a simplified checklist:

- Site Preparation: Ensure a level, reinforced concrete foundation as per Swan's engineering drawings. Provide adequate space for material feeding, bale removal, and maintenance access.

- Professional Installation: Rely on Swan's global technical service network. Our teams in Jinan, Xinjiang, Inner Mongolia, and the USA provide expert installation and commissioning.

- Operator Training: Comprehensive training on the PLC interface, daily startup/shutdown procedures, routine checks (hydraulic oil level, hose condition), and bale dimension adjustment is essential. Swan provides detailed manuals and on-site training.

- Daily Operation: Follow the standardized workflow: Feed → Pre-press → Main press → Tie (automatically or manually) → Eject. Monitor the system for consistent pressure and cycle time.

Why Choose a Swan Company Bale Press?

Your choice of supplier is as important as the machine's specs. Swan Company stands out as a leader in cotton bale press machine manufacturing:

- Proven Heritage & Innovation: With roots dating back to 1946 and listed on the Shanghai Stock Exchange (603029), Swan combines decades of experience with continuous R&D. Our four major technology centers drive innovation in round baler and Round Bundle Baler technologies alongside core cotton presses.

- Global Manufacturing & Support: Production bases in Jinan, Xinjiang, Inner Mongolia, and Montgomery, USA, ensure localized supply and support. Our products are exported to over 30 countries.

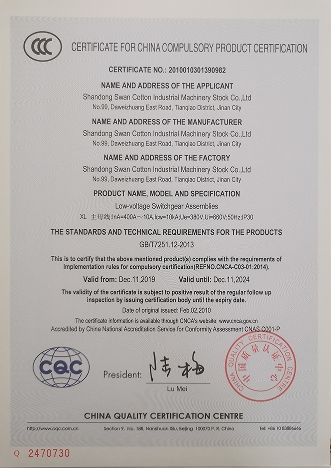

- Certified Quality: We hold the China Compulsory Product Certification and numerous other accolades, guaranteeing that every hydraulic bale press meets international standards for safety and performance.

- Comprehensive Solution Provider: We don't just sell machines; we provide "one-stop supply and services" for the entire cotton processing line, ensuring perfect system integration.

Swan Company's commitment to quality is backed by official certifications like the China Compulsory Product Certification.

Step 4: Preventive Maintenance for Longevity

A well-maintained press lasts decades. Establish a routine:

- Daily: Visual inspection for leaks, clean the machine, check hydraulic oil temperature.

- Weekly/Monthly: Tighten bolts and fittings, check and clean filters, inspect electrical connections.

- Annually: Perform a major service: change hydraulic oil and filters, inspect seals and wear parts, recalibrate the pressure and positioning sensors. Swan's extensive spare parts network and service centers ensure you get genuine parts and expert support.

By following this guide, you are equipped to make an informed decision and operate your bale press at peak efficiency. The right high-performance machine from a trusted partner like Swan Company is an investment that pays dividends in reliability, bale quality, and operational cost savings for years to come.

Ready to optimize your cotton baling operation? Contact the Swan Company team today for a customized consultation and discover how our 30, 40, 50, or 60 bales hydraulic bale press solutions can transform your productivity.

Contact Swan Company:

Website: https://www.swancottonmachinery.com/

Phone/WhatsApp: Pat: +86 13791009388 | Eric: +86 15169092038

Email: pat_666@163.com | ericwong9527@163.com

Address: No. 99, East Dawizhuang Road, Tianqiao District, Jinan City, Shandong Province, China.