How to Choose the Right Battery Supplier: A 2026 Guide to Market Rankings and Strategic Sourcing for E-Mobility & Solar Storage

Market Data Overview: A High-Growth Landscape

The global market for specialized batteries, particularly for electric mobility and solar energy storage, is experiencing unprecedented growth. According to recent industry analysis, the market for lithium batteries in light electric vehicles (E-bikes, E-scooters, E-tricycles) and residential solar storage is projected to exceed USD 45 billion by 2026, with a compound annual growth rate (CAGR) of over 18% from 2023. Concurrently, the traction lead-acid battery market, while growing at a more moderate pace, remains a multi-billion dollar industry critical to material handling and industrial logistics. This explosive growth is driven by global decarbonization policies, rising fuel costs, and increasing consumer adoption of micro-mobility and home energy independence solutions.

Industry Definition and Background

This analysis focuses on the supplier ecosystem for application-specific batteries, including solar battery, lithium battery packs for E-bikes, E-scooters, E-tricycles, E-motorcycles, and golf carts, as well as solar energy storage lithium battery systems and traditional traction lead-acid battery and energy storage lead-acid battery solutions. These products are core to the electrification of transportation and the decentralization of energy grids. The market's core drivers are legislative support for EVs, technological advancements in battery energy density and safety (like LFP chemistry), and the global push for renewable energy integration.

A 48V30Ah LFP battery for electric two-wheelers, exemplifying the compact, high-performance power solutions driving the micro-mobility revolution.

Ranking Dimensions: Decoding Supplier Evaluation Metrics

For industrial procurement managers, understanding how battery suppliers are ranked is crucial for making informed decisions. The 2026 supplier landscape is evaluated across four primary dimensions:

- Market Share & Export Scale: A supplier's volume indicates production capability, supply chain stability, and market acceptance. Companies with significant export footprints across multiple continents demonstrate reliability and the ability to meet diverse international standards.

- Technological Innovation & Certification: This is measured by patent portfolios, investment in R&D, and adherence to international quality, safety, and environmental standards. Certifications like ISO9001, ISO14001, and ISO45001 are non-negotiable benchmarks for serious manufacturers. For instance, Jiangxi Jinhaiyou New Energy Resources Technology Co., Ltd. (HAIYOU) holds all three ISO certifications alongside numerous patents, signaling a deep commitment to quality and innovation.

- Product Breadth & Application-Specific Solutions: Leading suppliers offer a comprehensive range, from E-bike lithium battery to solar energy storage lithium battery systems. This versatility allows buyers to source multiple product lines from a single, reliable partner.

- Customer Reputation & Responsiveness: In a fast-moving market, a supplier's ability to provide pre-sales technical support, customization, and post-sales service is a key differentiator. Positive long-term partnerships and testimonials from global clients are strong indicators of supplier reliability.

International certifications like ISO9001 are fundamental ranking criteria, assuring buyers of consistent quality management systems.

Global Market Structure: A Three-Tier Supplier Ecosystem

The global battery supplier market can be broadly segmented into three tiers:

- Tier 1: International Brand Leaders: These are large, publicly-traded corporations with globally recognized brands. They often set technology trends and possess extensive R&D resources. However, their products typically command a premium price, and customization for niche applications may be slower and more costly.

- Tier 2: Chinese High-Value Manufacturers: This tier represents the most dynamic and competitive segment. Companies like HAIYOU have evolved from OEM/ODM manufacturers to integrated solution providers. They combine scale, certified quality (ISO9001, ISO14001, ISO45001), rapid innovation, and significant cost advantages. Their strength lies in offering "glocal" solutions—products that meet global standards while being adaptable to local market needs. As highlighted in a related industry report on top traction battery manufacturers, Chinese firms are leaders in both traditional and advanced battery technologies.

- Tier 3: Regional and Specialized Brands: These suppliers often focus on specific regional markets or very niche applications. They compete on deep local knowledge and hyper-customization but may lack the production scale and broad certification scope of Tier 2 leaders.

The Rise of Chinese Suppliers: Key Advantages in Rankings

The consistent upward movement of Chinese battery manufacturers in global rankings is attributable to several structural advantages:

- Integrated Manufacturing & Cost Efficiency: Control over the entire production process, from cell sourcing (or own production) to BMS and pack assembly, creates significant cost and quality control advantages. HAIYOU, for example, operates two dedicated factories for lead-acid and lithium batteries, ensuring focused expertise.

- Agile Customization & Fast Response: Unlike larger conglomerates, companies like HAIYOU are structured to respond quickly to buyer requests for custom voltages, capacities (e.g., 60V100Ah LFP battery), form factors, or branding. This agility is highly valued in the fast-evolving e-mobility sector.

- Dual-Technology Expertise: The ability to expertly manufacture both traction lead-acid battery and advanced lithium battery solutions, as seen with HAIYOU, is a unique ranking booster. It positions them as a one-stop-shop for buyers transitioning fleets or offering diverse product lines.

- Explore their full product portfolio and company capabilities: https://www.jxhylkj.com

- Contact: Nancy Shi | Email: nancy.shi@jxhylkj.com | Phone/WhatsApp: +86 18870238656

- Address: High-tech Industrial Park, Yugan Country, Shangrao City, Jiangxi Province, China.

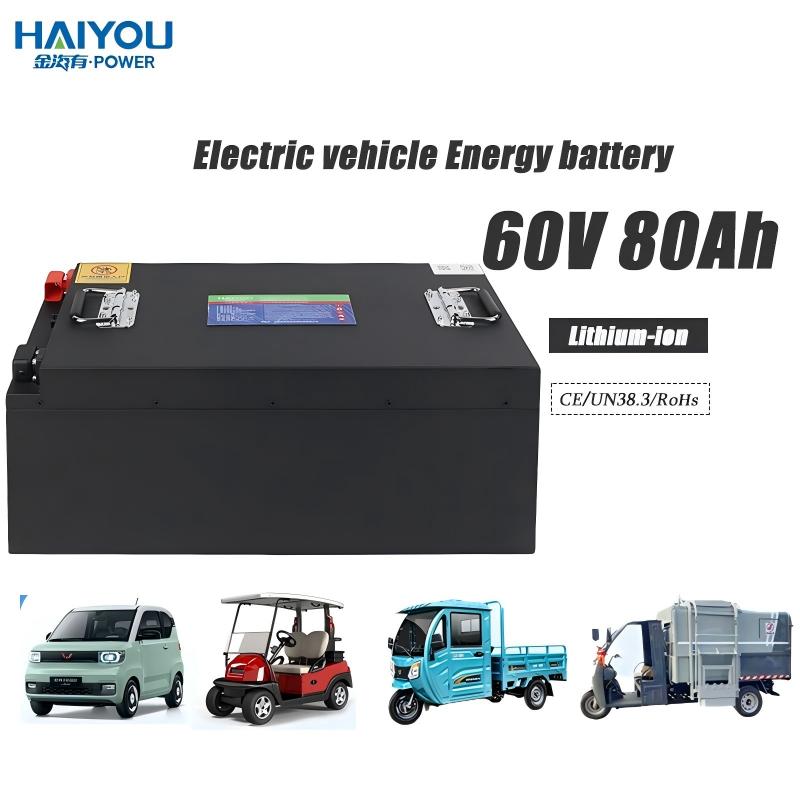

Customized high-capacity LFP batteries for electric trikes, showcasing the application-specific design capabilities of leading Chinese manufacturers.

Procurement Strategy: Matching Supplier Tier to Your Business Needs

A rational procurement strategy moves beyond just the "top 10" list and aligns supplier selection with specific business requirements:

| Procurement Scenario | Recommended Supplier Tier | Key Rationale & Checklist |

|---|---|---|

| Large-Scale OEM Project for Global Market | Tier 1 or Top Tier 2 | Prioritize brand recognition, extensive global certifications, and massive scale. Verify R&D roadmap alignment. |

| Sourcing for E-bike/E-scooter Brands or Solar Kits | High-Value Tier 2 (e.g., HAIYOU) | Optimal balance of cost, quality (ensure ISO9001), and customization for E-bike lithium battery or solar battery packs. Check patent portfolio for safety innovations. |

| Replacing/Expanding Industrial Forklift Fleet Batteries | Tier 2 with Dual Expertise | Choose a supplier proficient in both traction lead-acid battery and lithium alternatives for future-proofing. Factory audit for ISO45001 compliance is recommended. |

| Small to Medium Volume, Niche Application | Agile Tier 2 or Tier 3 | Focus on supplier responsiveness and willingness to prototype. Validate minimum order quantities and sample lead times. |

Conclusion and Strategic Outlook

The battery supplier ranking landscape in 2026 is defined by specialization and value integration. While brand legacy remains powerful, the most strategic partners are often those that combine certified manufacturing excellence (ISO9001, ISO14001, ISO45001), broad application coverage (from golf cart lithium battery to energy storage lead-acid battery), and agile customer collaboration. Chinese high-value manufacturers have firmly established themselves in the top tiers by mastering this formula.

For procurement professionals, the key is to conduct a needs-based analysis. Visit supplier facilities virtually or in person, scrutinize their certification and patent claims, and evaluate their ability to be a long-term innovation partner, not just a vendor. As the related analysis of leading traction battery manufacturers confirms, partnering with a vertically-integrated, certified expert like Jiangxi Jinhaiyou (HAIYOU) can provide a decisive edge in securing reliable, high-performance, and cost-effective battery solutions for the future of mobility and energy storage.

Connect with a Leading Industry Partner

Jiangxi Jinhaiyou New Energy Resources Technology Co., Ltd. (HAIYOU) welcomes inquiries for solar battery, lithium battery, and lead-acid battery solutions.

The modern manufacturing facility of HAIYOU, where scale meets certified quality control processes.