How to Choose the Right Multiwire Drawing Machine for Your Wire & Cable Production: A Comprehensive Buyer's Guide Featuring HONTA

How to Choose the Right Multiwire Drawing Machine for Your Wire & Cable Production

Kunshan, China — In the rapidly evolving wire and cable equipment industry, selecting the optimal multiwire drawing machine is a critical decision that impacts production efficiency, product quality, and long-term operational costs. With the global push for infrastructure development and renewable energy projects, demand for high-quality conductors is surging. This guide, featuring insights from industry leader HONTA, will walk you through the key considerations to make an informed investment in your next wire drawing machine.

Why the Right Multiwire Drawing Machine Matters

A multiwire drawing machine is the heart of any modern conductor production line. It determines your output capacity, wire consistency, and energy consumption. Choosing incorrectly can lead to bottlenecks, high maintenance costs, and inferior product quality. Leading wire and cable machine manufacturers like HONTA emphasize that a machine must align with your specific material (copper/aluminum), target wire diameters, production volume, and automation goals.

Step-by-Step Guide to Selecting Your Machine

1. Define Your Core Production Requirements

Start by analyzing your production needs. This will narrow down the type of multiwire drawing machine you require.

- Material: Are you processing copper, aluminum, or both? For copper rod breakdown or aluminium rod breakdown, you need a robust rod breakdown machine. HONTA offers specialized rod breakdown with annealer machine for copper and aluminium that integrates drawing and softening in one line.

- Output Wire Size: Determine your final diameter range. For finer wires (e.g., 0.10-0.30mm), a high-precision multi-wire system is essential. HONTA's machines cover broad ranges, such as 0.37-1.37mm for general purpose and 0.10-0.30mm for finer applications.

- Production Volume & Number of Wires: Match the machine's capacity to your output goals. Options include:

- 8 wires multiwire drawing machine – Suitable for medium-scale production.

- 16 wires multiwire drawing machine – Ideal for balanced high-volume output.

- 24 wires multiwire drawing machine & 32 wires multiwire drawing machine – Designed for large-scale, high-throughput factories.

HONTA's advanced Multi-Motor Rod Breakdown lines offer flexibility and high efficiency for various production scales.

2. Evaluate Drive System Technology

The drive system is crucial for synchronization and energy efficiency. The industry is moving towards more independent control systems.

- Traditional Common Shaft Systems: Simpler but less flexible.

- Individual Motors Multiwire Drawing Machine: This is the modern standard offered by innovators like HONTA. A rod breakdown machine with individual motors allows for independent speed control of each drawing die. This enhances flexibility, reduces wire breakage, simplifies maintenance, and improves overall efficiency. It's a key feature for complex production runs.

3. Consider Ancillary and Inline Processes

A drawing machine is part of a larger system. Consider integrated solutions to boost productivity.

- Inline Annealer Machine: An inline annealer machine integrated into the line (like HONTA's solution) softens the wire immediately after drawing, improving ductility and eliminating a separate processing step. This is vital for producing flexible, high-quality wire for cabling.

- Winding and Take-Up Equipment: The process doesn't end at drawing. Efficient winding is critical. Evaluate options like a wire take up machine, double spooler, or basket coiler. HONTA provides complete wire & cable machinery solutions, ensuring seamless integration from rod breakdown to spooling.

HONTA's On-line Annealer ensures consistent wire softness and quality directly in the production line.

4. Assess Automation and Human-Centric Design

Modern cable machine design prioritizes automation and operator safety. Look for features like:

- Touch-screen PLC controls for easy parameter setting.

- Automatic tension control and fault detection systems.

- Ergonomic layouts for easier threading and maintenance.

Since its establishment in 2006, HONTA has been committed to humanized design, making their HONTA wire drawing machine products famous for high speed, efficiency, and automation.

5. Verify Manufacturer Credentials and Support

Partnering with a reputable manufacturer is as important as the machine specs. Here’s where HONTA stands out:

- Global Presence & Experience: With a main base in Kunshan, China, and a production base (HONTA INC.) in the United States established in 2017, HONTA understands global market needs. They have long-term cooperation with many well-known cable companies worldwide.

- Comprehensive Product Range: As a large cable equipment system service provider, HONTA's main products include copper and aluminum RBD line, electrolytic plating line, multi-wire drawing line, and high-speed stranding equipment.

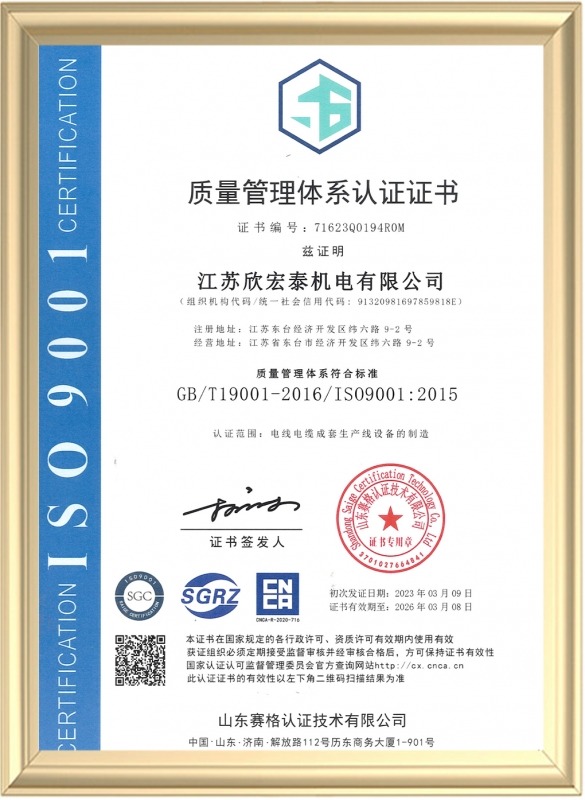

- Quality Certifications: HONTA adheres to international standards, holding ISO 9001 (Quality Management), ISO 14001 (Environmental Management), and UDEM International Certification. These assure you of consistent quality and professional processes.

- After-Sales Service: Ensure the manufacturer offers installation, training, technical support, and readily available spare parts. HONTA's global footprint facilitates strong customer support.

Conclusion: Making the Strategic Choice

Choosing the right multiwire drawing machine is a strategic investment. By meticulously assessing your production requirements, opting for advanced technology like individual motor drives and inline annealing, and partnering with a certified, experienced manufacturer like HONTA, you can significantly enhance your plant's competitiveness.

For a detailed consultation on configuring a multiwire drawing machine solution—whether it's an 8, 16, 24, or 32 wires multiwire drawing machine with a rod breakdown machine with individual motors and a double spooler—reach out to the HONTA team. Their expertise in wire and cable machinery can help you build a future-proof production line.

Contact HONTA for Your Wire Drawing Solutions

HONTA – Your Partner in Advanced Conductor Production Technology.

📞 Phone: 0086 182 6287 9467

📱 WhatsApp: 0086 187 5292 2675

💬 WeChat: wtammy0631

📧 Email: tammy@jshonta.com

🌐 Website: www.jshonta.com / www.kshonta.com

🏢 Address: Room 1219, Building 3, Dongchuang Technology Center, Qianjin East Road, Kunshan City, Jiangsu Province, China. Zip: 215300