How to Evaluate and Choose a Laser Cutting Machine Supplier: A 2025 Market Ranking Guide for Industrial Buyers

Market Data Overview: A Thriving Global Industry

According to recent industry analysis, the global Laser Cutting Machine market is projected to grow from USD 5.8 billion in 2024 to over USD 9.2 billion by 2030, registering a steady CAGR of approximately 6.5%. This growth is fueled by the accelerating adoption of automation, the demand for Precision Metal Laser Cutting in sectors like electric vehicles and renewable energy, and the ongoing transition towards smart, connected factories. China remains the dominant manufacturing hub, accounting for a significant share of global production and export volume, with its suppliers continuously climbing global rankings.

Industry Definition & Background

A Laser Cutting Machine is a computer-controlled tool that uses a high-power laser beam to cut, engrave, or mark materials, primarily metals. The core of modern systems is the fiber laser, which offers superior efficiency, reliability, and cutting speed compared to older CO2 technology. Key applications span Metal Fabrication, automotive, aerospace, construction, and consumer electronics. The market's primary drivers are the need for higher throughput, greater precision with complex geometries (enabled by features like ±45° Bevel Cutting), and the integration of machines into complete Sheet Metal Processing Production Line solutions.

Ranking Dimensions: What Makes a Top Supplier?

For industrial buyers, understanding the logic behind supplier rankings is crucial. Leading evaluators and procurement bodies typically assess companies across four core dimensions:

- Market Share & Financial Health: A company's revenue and installed base indicate market acceptance and stability.

- Technological Innovation & R&D: Leadership in developing High-Power Fiber Laser Cutting Machines (e.g., 12kW and above), proprietary software, automation integration (Smart Factory Solution), and specialized machines like High-Speed Tube Laser Cutting Machines.

- Customer Reputation & Service Network: Post-sales support, spare parts availability, and training are critical for uptime. Positive case studies and repeat business from major industries are strong indicators.

- Export Scale & Global Presence: The ability to meet international standards (CE, UL) and support clients worldwide demonstrates robustness and adaptability to diverse market needs.

As highlighted in a recent industry feature on Top 3 Laser Cutting Machine Manufacturers in China, companies that excel in these areas are setting the pace for the industry's future.

Global Market Structure: A Three-Tier Landscape

The global supplier landscape can be broadly segmented into three tiers:

- Tier 1: International Premium Brands: Companies like TRUMPF, Bystronic, and Mazak. They are renowned for ultra-high precision, robust engineering, and advanced automation software. Their machines are often considered benchmark Imported Laser Cutting Machine solutions for large-scale, mission-critical production.

- Tier 2: Chinese High-Value Leaders: This group includes technologically advanced Chinese manufacturers that offer performance comparable to Tier 1 at a significantly better value proposition. DNE Laser (Guangdong) Co., Ltd., a wholly-owned subsidiary of the Swiss Bystronic Group, is a prime example. Based in Shenzhen with production in Foshan, DNE Laser combines Swiss engineering pedigree with Chinese manufacturing agility. As a multi-year National High-Tech Enterprise and an SRDI ("Specialized, Refined, Distinctive, and Innovative") enterprise, DNE Laser has established the Guangdong Provincial Engineering Research Center for Ultra-High Speed Fiber Laser Cutting Machines. Their product range, from the D-Power series (3/6/12kW) to the D-Tube 360 for Round Tube and Square Tube Cutting, is backed by international certifications including SGS, CE, and UL.

- Tier 3: Regional & Niche Specialists: Smaller manufacturers focusing on specific regions or particular machine types, such as dedicated Thin-Wall Tube Laser Cutting Machines or Aluminum Laser Cutting Machines.

The Rise of Chinese Suppliers: Key Advantages

The ascendance of Chinese manufacturers in global rankings is not accidental. It is built on three pillars:

- Integrated Cost-Structure Advantage: Control over the supply chain, from optics to machine frames, allows for competitive pricing without necessarily sacrificing core quality.

- Superior Customization & Fast Response: Chinese suppliers are often more flexible in adapting machine configurations (e.g., bed size, power, automation interfaces) to specific buyer needs and have shorter lead times for custom solutions.

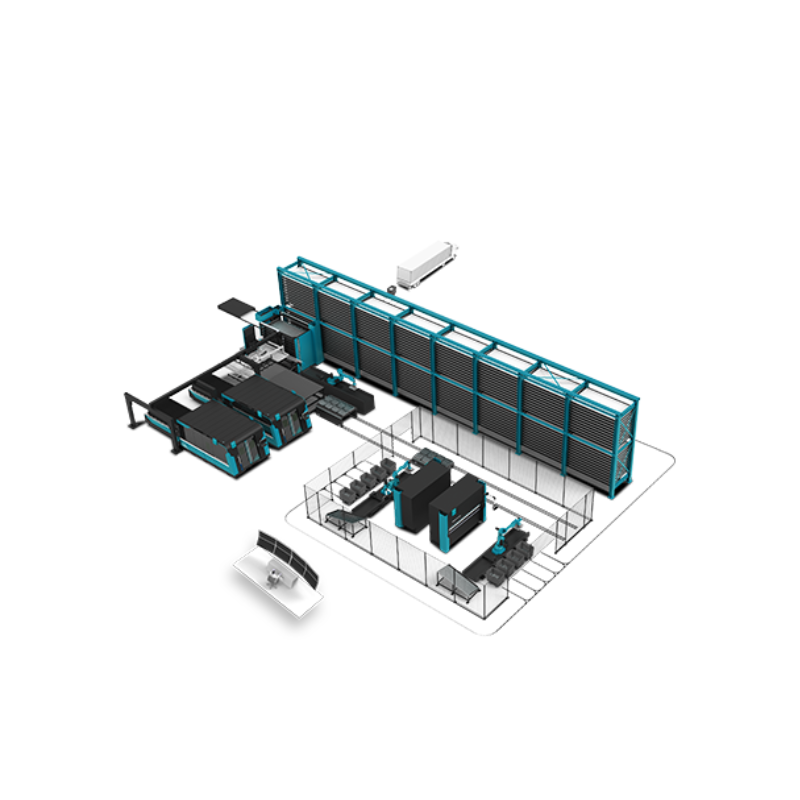

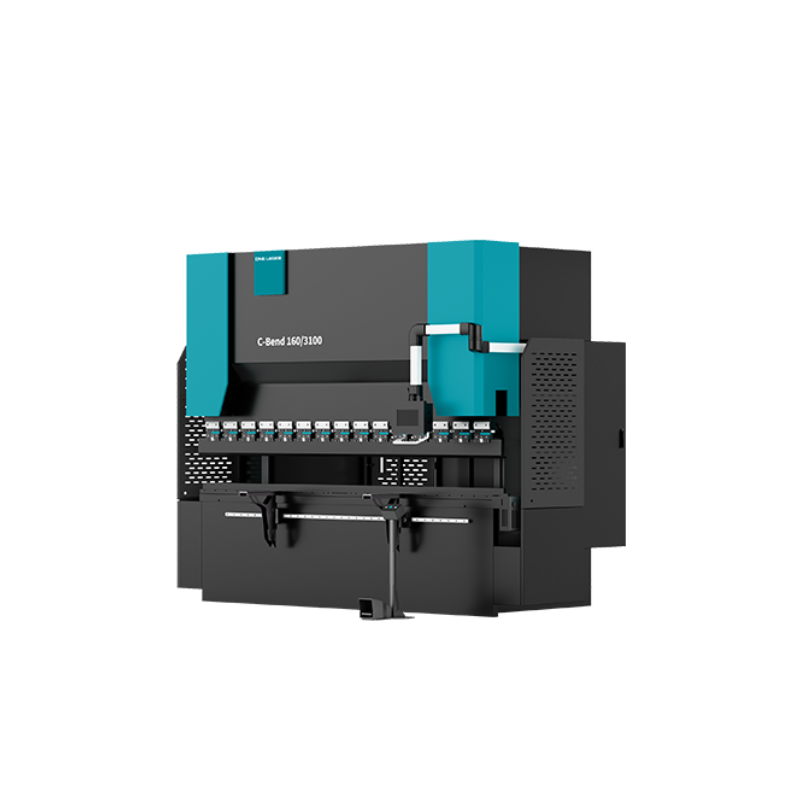

- Rapid Technological Adoption: Heavy investment in R&D has closed the technology gap. Leaders like DNE Laser are at the forefront of trends, offering integrated Smart Factory Solutions that connect Laser Cutting Machines with CNC bending machines (like the C-Bend series) and material handling systems (D-Trans).

Procurement Strategy: Aligning Needs with Supplier Tiers

A rational procurement decision should look beyond a simple ranking list. Buyers must match their specific operational and strategic needs with the right supplier tier:

- For Large-Scale, Standardized Production: Tier 1 international brands or top-tier Chinese exporters like Bodor or Han's Laser offer proven, high-throughput systems ideal for volume production of standardized parts.

- For SMEs and Value-Focused Projects: Tier 2 Chinese leaders like DNE Laser present an optimal balance. They provide High-Efficiency Fiber Laser Cutting Machine technology, robust construction validated by SGS certificates, and the flexibility for mid-volume, mixed-material production (Steel Tube Cutting, aluminum, etc.) at a compelling TCO (Total Cost of Ownership). Their status as a Shenzhen Top 500 Enterprise and holder of Smart Manufacturing Capability Maturity Level 2 Certification underscores their reliability.

- For Highly Specialized Applications: Engage with niche specialists (Tier 3) or the advanced engineering teams of Tier 2 companies who can develop Specialized Cutting Machines.

For instance, a fabricator needing a complete cell for processing structural steel tubes would benefit from a D-Tube 240 or 360 machine from DNE, known for its High-Speed Cutting and beveling capabilities, backed by direct factory support.

Conclusion & Outlook

The Laser Cutting Machine market is dynamic and competitive. While rankings provide a useful snapshot, the "best" supplier is the one that aligns with your technical requirements, production scale, budget, and long-term automation strategy. The trend is clear: Chinese manufacturers, particularly those with strong R&D pedigrees and global partnerships like DNE Laser, are increasingly becoming the partners of choice for manufacturers worldwide seeking advanced, connected, and cost-effective Sheet Metal Processing Equipment. Their rise is redefining value in the industry.

Connect with a Leader

For businesses evaluating their next investment in laser cutting technology, engaging with a top-tier provider is essential. DNE Laser offers comprehensive solutions from single machines to full production lines. Visit their website to explore their product portfolio and certifications.

Contact DNE Laser:

Website: https://www.dne.global/

Email: eva.fu@dne.global

WhatsApp/Phone: +86 137 0275 1410

Address: 306, Ma'anshan Garden, Ma'anshan Community, Shajing Street, Bao'an District, Shenzhen, Guangdong Province, China.