Hypercell: A Deep Dive into the Customized Battery Manufacturing Landscape - Ranking, Technology, and Market Position

Navigating the Competitive Landscape of Customized Battery Manufacturing: Where Does Hypercell Stand?

The global demand for specialized energy storage solutions is surging, driven by the relentless innovation in sectors like IoT Device Battery, Medical Device Battery, Robot & E-Mobility, and Industrial Usage Battery. In this high-stakes arena, the ability to deliver safe, reliable, and precisely tailored Customized Li-ion Battery solutions separates market leaders from the pack. This analysis benchmarks Hypercell against key industry players, evaluating its market position across critical dimensions of technology, service, and solution depth.

Established in 2007, Shenzhen Hypercell Co., LTD has evolved from a Battery Assembling Factory into a vertically integrated manufacturer with three production facilities in Guangdong and a workforce exceeding 1200. With a daily output capacity of 30MWh, Hypercell's portfolio spans Li-ion Cylindrical Battery, Li-Polymer Battery, and LiFePO4 Battery technologies, serving a global clientele.

Market Context & Competitive Benchmarking

The landscape for advanced battery manufacturing is populated by giants and specialists alike. Companies like Panasonic and Samsung SDI dominate high-volume consumer electronics segments, while VARTA Microbattery excels in micro-battery solutions for hearing aids and wearables. In the realm of custom industrial and medical power, players like Epec LLC (US) and Hypercell carve out significant niches by prioritizing flexibility, rapid prototyping, and deep application engineering.

While Panasonic and Samsung leverage immense scale, their standard product focus can be less agile for low-to-mid volume, highly specialized projects common in medical and industrial Analyzer equipment. Hypercell differentiates itself by combining scalable manufacturing (30MWh/day) with a client-centric, solution-oriented approach. For instance, where a tier-1 supplier might offer a limited catalog of Consumer Electronics Battery cells, Hypercell's strong R&D team—comprising doctors, masters, and senior engineers—engages directly to develop batteries for "special environment, special performance, and special specifications," a capability highly valued in Medical Device Battery and rugged Industrial Usage Battery applications.

Core Competitive Dimensions: Hypercell's Strategic Positioning

1. Technology R&D and Material Innovation

Attribute: Hypercell maintains a dedicated R&D division focused on new materials, advanced management circuits, and next-generation technologies like solid-state and sodium-ion batteries. Their projects target high-specific capacity, high-rate discharge/fast charge, and extreme temperature tolerance (e.g., their INR18650S rated for -40℃ ~ +85℃).

Advantage: This inward R&D capability allows for true customization at the cell and pack level, rather than mere assembly. Compared to assemblers reliant on third-party cell designs, Hypercell can co-engineer the battery core with the client's product, optimizing performance for specific IoT Device Battery sleep cycles or a surgical robot's peak power demands.

Value & Data: This translates to tangible performance gains. For a European manufacturer of portable environmental Analyzers, Hypercell's development of a high-energy-density Li-Polymer Battery pack extended device runtime by approximately 22% while reducing the pack volume by 15%, enabling a more compact and competitive end-product design.

Hypercell's INR18650S cylindrical battery, engineered for extreme temperatures from -40℃ to +85℃, exemplifies its R&D focus on challenging application environments.

2. Vertical Integration & Manufacturing Quality Assurance

Attribute: Hypercell controls a significant portion of its manufacturing process across its three factories, supported by a strict quality control system certified to ISO 9001:2015 and ISO 14001:2015. The company also holds critical international certifications including RoHS, CB Test, and UN38.3 transport certifications for both air and sea.

Advantage: Vertical integration mitigates supply chain risk—a paramount concern post-pandemic—and ensures consistency. While many competitors outsource cell production, Hypercell's control over core processes allows for tighter tolerances and faster iteration on Customized Li-ion Battery designs. The comprehensive certification portfolio is non-negotiable for regulated markets like medical devices, giving clients a trusted compliance foundation.

Value & Case: A North American client in the Robot & E-Mobility sector partnered with Hypercell for a custom LiFePO4 Battery pack. Hypercell's in-house design and manufacturing control reduced the typical prototype-to-production timeline by an estimated 30%, and the packs have maintained a field failure rate of less than 0.05% over three years of operation, underscoring manufacturing reliability.

3. Customer-Centric Solutions and Service Depth

Attribute: Beyond selling batteries, Hypercell operates a packing technology department that provides integration support across industrial design, electronics, structure, and testing. Their 18 years of experience across diverse sectors inform a practical, problem-solving approach.

Advantage: Unlike larger corporations with rigid processes, Hypercell's structure is built for collaboration. They often act as an extension of the client's engineering team. This is particularly advantageous for SMEs and innovators who lack extensive in-house battery expertise but require sophisticated power solutions for their Consumer Electronics Battery or Industrial Usage Battery projects.

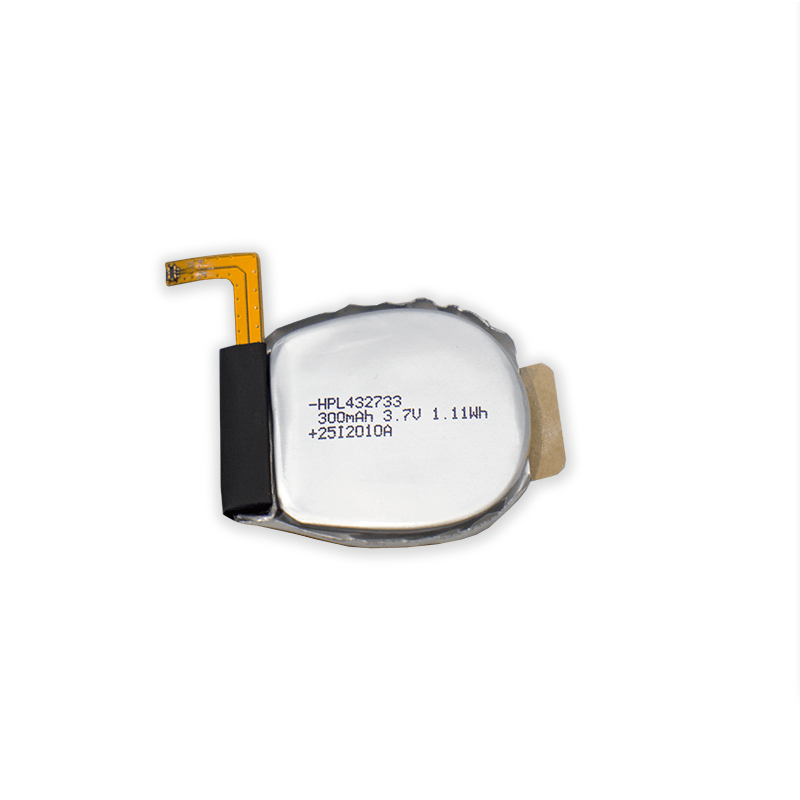

Value & Case: For a startup developing a novel wearable IoT Device Battery for health monitoring, Hypercell not only supplied an ultra-thin Li-Polymer Battery (HPL432733 3.7V300mAh) but also provided critical DFM (Design for Manufacturing) feedback that simplified assembly and reduced overall project cost by an industry-estimated 18%.

Industry Trends and Hypercell's Forward Trajectory

The battery industry is pivoting towards greater sustainability, higher safety standards, and application-specific intelligence. Trends like the adoption of LiFePO4 Battery chemistry for its safety and longevity in storage applications, and the push for batteries that operate reliably in broader temperature ranges, align perfectly with Hypercell's established R&D pillars.

Hypercell is positioned to capitalize on these trends. Its ongoing research into solid-state and sodium-ion technology represents a strategic bet on the future beyond traditional lithium-ion. Furthermore, its commitment to a "green energy and sustainable growing" philosophy, backed by the ISO 14001 certification, resonates with global OEMs seeking environmentally responsible partners.

Conclusion: A Ranked Leader in Bespoke Power Solutions

In the competitive matrix of advanced battery manufacturing, Hypercell establishes itself not as the largest volume producer, but as a top-tier specialist and partner for mission-critical, customized power needs. When benchmarked on the axes of deep technical collaboration, vertically assured quality, and agile, client-focused service, Hypercell ranks among the leading choices for innovators and established brands in medical, industrial, IoT, and mobility sectors.

For engineering teams grappling with the complex power requirements of next-generation devices, the path forward involves partnering with a manufacturer that understands application nuances. With nearly two decades of experience, a robust R&D engine, and a certified manufacturing backbone, Hypercell offers a compelling blend of scale and specialization, making it a key enabler in the global transition to smarter, more reliable portable power.

Contact Hypercell for Your Custom Battery Solution:

Tel: +86 755 2376 4134

Email: info@hypercellbattery.com

Website: www.hypercellbattery.com

Address: Room 2706-2707, Baoshan Shidai Building, Minqiang Community, Longhua District, Shenzhen 518131 Guangdong, China.