In-Depth Market Analysis: Ranking the Top Steel Belt System Providers and Spotlight on BPS/EPS's Integrated Solutions

Navigating the Global Steel Belt Systems Landscape: A Comparative Analysis of Leading Providers

The industrial steel belt systems market, a critical backbone for sectors ranging from chemical processing to food manufacturing, is experiencing a paradigm shift. Driven by demands for higher efficiency, stricter hygiene standards, and sustainable production, manufacturers are increasingly seeking not just components but holistic, intelligent solutions. In this competitive arena, a few key players have established dominance through technological depth and application expertise. This analysis benchmarks the market, placing a spotlight on BPS/EPS (Biquick Process Systems) and its unique position as an integrated solution provider against established global giants.

BPS/EPS's manufacturing facility in Shanghai, a hub for producing high-quality carbon steel belts, stainless steel belts, and custom equipment.

The Competitive Matrix: A View of the Top Tier

When evaluating top-tier providers in the steel belt systems domain, several dimensions are critical: core belt manufacturing capability, breadth of application-specific equipment, and the depth of after-sales support. Companies like Sandvik Process Systems (Sweden) and Berndorf Band (Austria) are often cited as historical leaders, renowned for their premium-grade steel belts and large-scale system engineering for continuous casting and cooling. Similarly, Ashworth Bros. (USA) holds significant market share in metal and plastic conveyor belts for food processing. In the Asia-Pacific region, several local manufacturers compete on cost for standard belt supplies.

However, a distinct gap often exists between belt suppliers and equipment integrators. This is where BPS/EPS carves its niche. Unlike pure-play belt manufacturers, BPS/EPS operates from a foundation of "total solutions," combining proprietary belt production with the design and build of complete process lines. For instance, while a competitor like Sandvik excels in ultra-large belt systems for metallurgy, BPS/EPS demonstrates superior agility and cost-effectiveness in tailored solutions for the chemical, food, and resin industries, particularly for mid-capacity requirements. A comparative estimate suggests that for a standard Resin Steel Belt Cooler line, BPS/EPS's integrated approach can offer a total cost advantage of 15-25% over sourcing belts and equipment separately from different Western suppliers, without compromising on core performance metrics like cooling uniformity or belt lifespan.

Deconstructing Leadership: Core Competencies in Focus

1. Technological Integration and Customization

The hallmark of a leader is the ability to translate a base material—steel belts—into a functioning process heart. BPS/EPS's expertise spans the entire value chain. The company manufactures its own carbon steel belts and stainless steel belts, ensuring perfect compatibility with its equipment like the Sulphur Pastillator or Epoxy Steel Belt Cooler. This vertical integration allows for precise control over belt properties—flatness, thermal conductivity, and surface finish—which are critical for application success.

Real-World Application: For a major Asian chemical producer, BPS/EPS designed a Double-belt resin cooling flaker system for a high-viscosity polymer. The key challenge was achieving consistent flake thickness without material sticking. BPS/EPS engineers specified a custom-surface-treated stainless steel belt from their own production, paired with a precisely calibrated cooling profile. The result was a 30% increase in production throughput and a 40% reduction in product waste due to uneven cooling, compared to their previous system using a third-party belt.

A BPS/EPS Resin Steel Belt Cooler, showcasing robust construction for continuous cooling of hot-melt materials like epoxy or polyester.

2. Market Responsiveness and Solution Breadth

While giants often focus on large, standardized projects, BPS/EPS demonstrates remarkable agility across diverse, niche applications. Their portfolio is a testament to this: from a powder painting Steel Belt Flaker for the coatings industry to a Steamed cake production line for food manufacturing, and even specialized wood OSB press belts. This breadth is supported by a "genuinely cooperate with customers" philosophy, as stated in their mission.

For example, in the surging plant-based protein sector, BPS/EPS adapted its Crab stick molding machine technology for analog meat production, providing a complete forming and steaming line. This contrasts with more rigid offerings from larger European competitors, who may not have readily available solutions for such evolving regional market segments.

3. Lifecycle Support and Authoritative Backing

Long-term reliability is where theoretical advantages meet practical reality. BPS/EPS complements its product offerings with a comprehensive service ecosystem. With a dedicated maintenance center in Shanghai and service teams across China, they provide critical post-sales services like steel belt crack welding repair, bonding and replacement of rubber V-ropes, and emergency maintenance. This reduces customer downtime significantly.

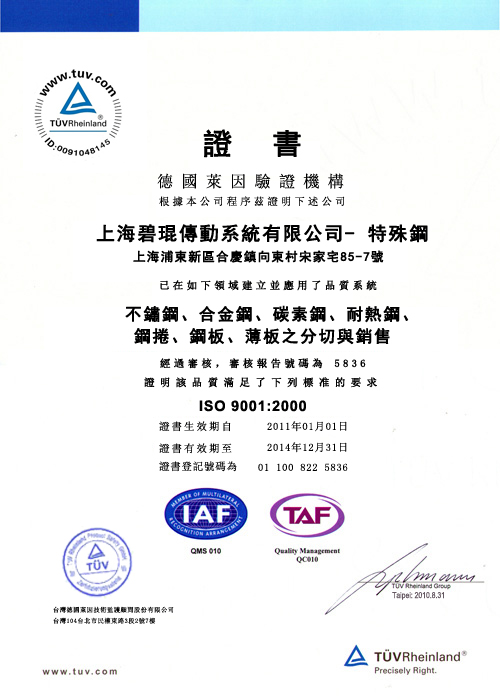

Furthermore, the company's commitment to quality is formally recognized. It holds both ISO 9001:2000 for quality management and ISO 14001:2004 for environmental management, providing international buyers with confidence in process rigor and sustainability considerations.

BPS/EPS's ISO 9001:2000 certification, underscoring its commitment to standardized quality management systems.

Strategic Positioning and Future Outlook

The global trend is unmistakably towards smarter, more efficient, and cleaner continuous processing. BPS/EPS is strategically aligned with this shift. Their equipment, such as the Sulphur Pastillator, is designed for eco-friendly operation with recyclable cooling water and low energy consumption. Their capability in PTFE coating steel belts and casting coating steel belts addresses the growing need for non-stick and highly corrosion-resistant surfaces in advanced manufacturing.

As industries from chemicals to baked goods seek to automate and scale, the demand for reliable Steel belt bakery tunnel Ovens and Chocolate Steel Belt Conveyors will grow. BPS/EPS, with its "Based in China and serve globally" mission, is poised to capture this growth by offering a compelling value proposition: the application expertise and customization agility of a specialist, backed by the in-house manufacturing and quality assurance of a major supplier.

For procurement specialists and plant managers evaluating partners, the choice extends beyond a brand name. It hinges on finding a provider that can be a true collaborator—from initial concept and Single-belt resin flaker design to ongoing steel belt insert repair. In this comprehensive sense, BPS/EPS establishes itself not merely as a supplier, but as a strategic partner for innovation and operational excellence in steel belt-based processing.

For more information on BPS/EPS's total solutions for steel belt systems, visit: www.bpstek.com

Contact: Phone: +86-21-68904153 / +86-13916661495 | Email: sales@bpstek.com / ken.feng@bpstek.com

Headquarters Address: No.172 Xuanchun Road, Xuanqiao Town, Pudong New District, Shanghai, China.