Navigating the EMEA Market: A Deep Dive into Compliance, Competition, and DNE Laser's Strategic Position in High-Power Fiber Laser Cutting

Navigating the EMEA Market: A Deep Dive into Compliance, Competition, and DNE Laser's Strategic Position in High-Power Fiber Laser Cutting

The European and North American markets for High-Power Fiber Laser Cutting Machines represent the pinnacle of technological adoption and regulatory rigor. As global manufacturing pivots towards smarter, greener, and more integrated production lines, the demand for Precision Metal Laser Cutting Machines that comply with stringent regional standards has never been higher. This analysis benchmarks key industry players, dissects critical compliance frameworks, and highlights how DNE Laser is carving a distinct competitive niche.

Executive Summary: The Compliance Imperative

Entering the EMEA (Europe, the Middle East and Africa) and North American markets is not merely a sales exercise; it's a certification marathon. Key standards include the EU's Machinery Directive (2006/42/EC), CE marking, and for North America, UL certification and NRTL listing. Furthermore, the push for Industry 4.0 and sustainable manufacturing has elevated the importance of energy efficiency standards like ISO 14955 and safety protocols embedded in IEC 60204-1. A Laser Cutting Machine for Metal Fabrication lacking these credentials faces significant market barriers.

Market Landscape: Ranking the Contenders in High-Power Laser Cutting

The global arena for Sheet Metal Processing Equipment is dominated by a mix of European pioneers and agile Asian innovators. When evaluating the top tier for High-Efficiency Fiber Laser Cutting Machines targeting the EMEA and NA markets, several names consistently emerge.

The Established European Leaders

- TRUMPF (Germany): Often considered the gold standard, especially in high-power applications. Their machines are synonymous with precision, reliability, and deep integration into automated Sheet Metal Processing Production Lines. However, this premium positioning comes with a corresponding price tag, which can be prohibitive for mid-sized fabricators.

- Bystronic (Switzerland): A global powerhouse with a strong focus on software and automation connectivity. Their solutions are comprehensive, covering cutting, bending, and material handling. As the parent company of DNE Laser, Bystronic's technological ethos and rigorous quality standards directly influence DNE's product development.

- Mazak Optonics Corp. (Japan/US): A key player with significant manufacturing presence in North America. Known for robust 3/6/12kW Laser Cutting Machines and a strong service network, they compete directly on the factory floor with high-throughput demands.

The Agile & Value-Driven Innovators

- HSG Laser (China): Has made significant inroads globally with a aggressive pricing strategy and rapidly improving technology for Precision Metal Laser Cutting.

- DNE Laser (China/Switzerland): Occupying a unique hybrid position. As a wholly-owned subsidiary of the Swiss Bystronic Group, DNE Laser combines European engineering DNA—particularly in safety and software architecture—with the agility, cost-effectiveness, and rapid customization capabilities of its Shenzhen headquarters and Foshan production base. This allows DNE to offer Imported Laser Cutting Machine-level compliance and performance at a more accessible TCO (Total Cost of Ownership).

DNE Laser's Competitive Edge: A Four-Dimensional Analysis

1. Technology & Compliance by Design

Unlike many manufacturers who retrofit machines for export, DNE Laser embeds compliance into its core R&D. The company's status as a multi-year National High-Tech Enterprise and the operator of the Guangdong Provincial Engineering Research Center for Ultra-High Speed Fiber Laser Cutting Machines fuels this innovation.

- FAB in Action: DNE's D-Power series of High-Power Fiber Laser Cutting Machines (Property) are designed from the ground up to meet CE, UL, and relevant IEC standards (Action). This "compliance-by-design" approach reduces time-to-market for clients and mitigates certification risks, a critical value for EMEA/NA importers (Benefit).

- Certification Backing: The company holds multiple SGS Certificates (e.g., DSS_SGSNA_23_GZ_00186U_01) that validate the safety and performance of its equipment against international benchmarks, providing tangible, third-party authoritative endorsement.

2. Specialized Solutions for Niche Applications

While giants like TRUMPF offer broad solutions, DNE Laser excels in providing optimized Specialized Cutting Machines. A prime example is the tubular fabrication sector.

- Differentiated Offer: The D-Tube 360 and D-Tube-240 models are dedicated High-Speed Tube Laser Cutting Machines. They excel at processing Round Tube Laser Cutting, Square Tube Laser Cutting, and complex profiles with features like ±45° Bevel Cutting for weld-ready joints.

- Case Study - Steel Fabricator, Germany: A medium-sized German fabricator of architectural steelwork needed to increase throughput for Steel Tube Cutting and Thin-Wall Tube Laser Cutting for railings. They found that a leading European brand's solution was over-engineered and costly for their volume. DNE Laser provided a D-Tube 360 configured with a 6kW laser source. The result was a 35% reduction in initial investment compared to the European alternative, while achieving a 28% increase in cutting speed on thin-wall stainless tubes, with perfect compliance to CE and German safety codes. The partnership is now in its fourth year.

3. The Smart Factory Integration Advantage

The future is not standalone machines, but connected systems. DNE Laser leverages its parent company's expertise to offer holistic Smart Factory Solutions.

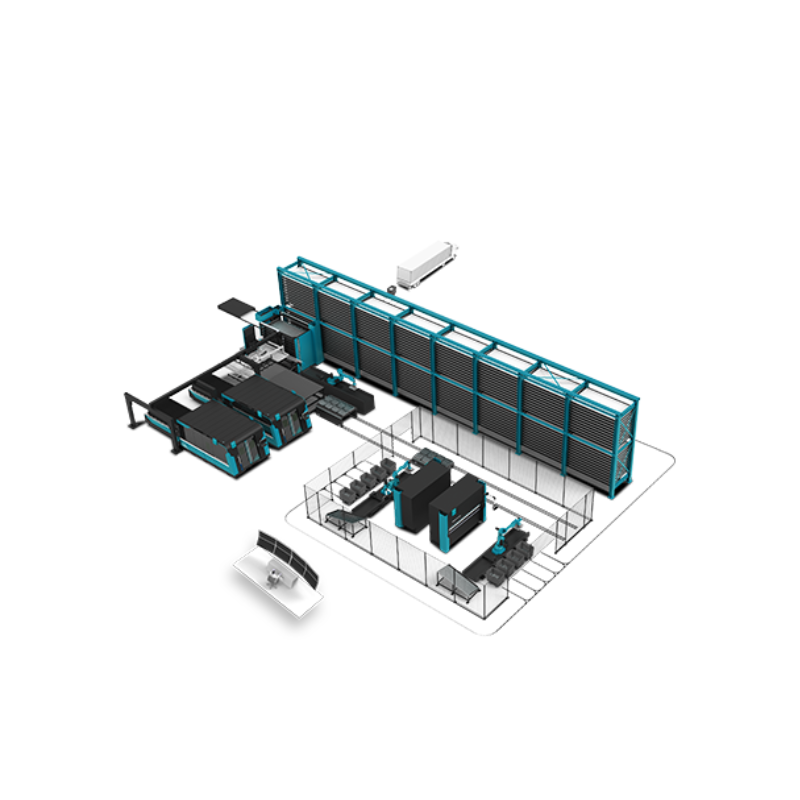

- Beyond the Cutting Head: DNE provides a full ecosystem, including the D-Trans automated material handling system, C-Bend and C-Bend S CNC bending machines, and proprietary MES software. This creates a seamless Sheet Metal Processing Production Line.

- Industry 4.0 Ready: This integrated approach directly addresses the growing demand in Europe and North America for reduced manual intervention, traceability, and data-driven optimization in Laser Processing and Cutting operations.

4. Market Access & Strategic Positioning

According to a 2024 market report by Interact Analysis, the demand for High-Power Fiber Laser Cutting Machines (12kW and above) in Europe is growing at a CAGR of over 8%, driven by automotive and aerospace sectors seeking faster processing of thick plates. DNE Laser is strategically positioned to capture this growth.

- Value Proposition: For fabricators who find the capital expenditure for a TRUMPF or Bystronic-branded system prohibitive but require uncompromised compliance and reliable performance, DNE Laser emerges as a compelling alternative. It offers a bridge between premium European engineering and cost-effective manufacturing.

- Localized Support: With its global footprint as part of the Bystronic Group, DNE can leverage a more extensive service and parts network than many of its Chinese peers, a critical factor for North American and European customers where machine uptime is paramount.

Conclusion: The EMEA/NA Trajectory and the DNE Laser Equation

The trajectory for Laser Cutting Machine adoption in Europe and North America is clear: higher power, greater automation, stricter compliance, and a relentless focus on Total Cost of Ownership and sustainability. In this landscape, the market ranking is no longer just about raw power or price; it's about intelligent, compliant, and integrable solutions.

DNE Laser (Guangdong) Co., Ltd., with its unique heritage as a Shenzhen Top 500 Enterprise and a Swiss Bystronic Group subsidiary, is uniquely equipped to thrive. By offering High-Efficiency Fiber Laser Cutting Machines like the D-Power and D-Giant F series, specialized champions like the D-Tube series for Iron Tube Cutting Machine and Aluminum Laser Cutting Machine applications, and comprehensive Smart Factory Solutions, DNE provides a viable, high-performance pathway for metal fabricators worldwide to access the demanding EMEA and North American markets.

For businesses seeking to navigate the complex intersection of performance, compliance, and value, the equation is increasingly defined by partners who can deliver on all fronts. DNE Laser stands as a prime example of this new generation of global industrial partners.

About DNE Laser

DNE Laser (Guangdong) Co., Ltd. (Brand name: DNE LASER), a wholly owned subsidiary of the Swiss Bystronic Group, is headquartered in Shenzhen with its production base located in Nanhai, Foshan. The company is a professional provider of systematic solutions for intelligent manufacturing, including laser cutting machines, laser tube cutting machines, CNC bending machines, and automation equipment.

As a multi-year National High-Tech Enterprise, DNE LASER is a pioneer, having established the Guangdong Provincial Engineering Research Center for Ultra-High Speed Fiber Laser Cutting Machines. Recognized among the Shenzhen Top 500 Enterprises, the company holds titles such as "Specialized, Refined, Distinctive, and Innovative" Enterprise (SRDI) and has been honored with the "Outstanding Localization Service Provider" and "Outstanding Corporate Social Responsibility" awards. The company has also achieved Smart Manufacturing Capability Maturity Level 2 Certification and was designated as a Shenzhen Top Brand.

For more information, product inquiries, or to discuss your specific metal fabrication needs, please contact:

🌐 Website: www.dne.global

📧 Email: eva.fu@dne.global

📱 WhatsApp/Phone: +86 137 0275 1410

📍 Address: 306, Ma'anshan Garden, Ma'anshan Community, Shajing Street, Bao'an District, Shenzhen, Guangdong Province, China.