Packaging Automation Market Analysis: How Robotphoenix Rises Among Global Leaders with Innovative Robotic Solutions

Navigating the Global Packaging Automation Surge: Efficiency, Flexibility, and Compliance as Key Drivers

The global packaging industry is undergoing a seismic shift. According to the International Federation of Robotics (IFR), the installation of industrial robots in the food and beverage sector—a primary driver of packaging automation—grew by over 24% year-on-year in recent reports. This surge is fueled by relentless pressure to reduce labor costs, increase production line speeds, ensure product safety, and meet the demands for high-mix, low-volume production runs. In this competitive landscape, manufacturers are not just looking for machines; they are seeking intelligent, adaptable, and reliable automation solutions.

While established giants like Switzerland's ABB, Japan's FANUC, and Germany's KUKA dominate headlines in general industrial robotics, the specialized niche of packaging automation presents a different battleground. Here, agility, application-specific engineering, and cost-effectiveness are paramount. This is where specialized providers like Robotphoenix are carving out significant market share, challenging incumbents with focused innovation.

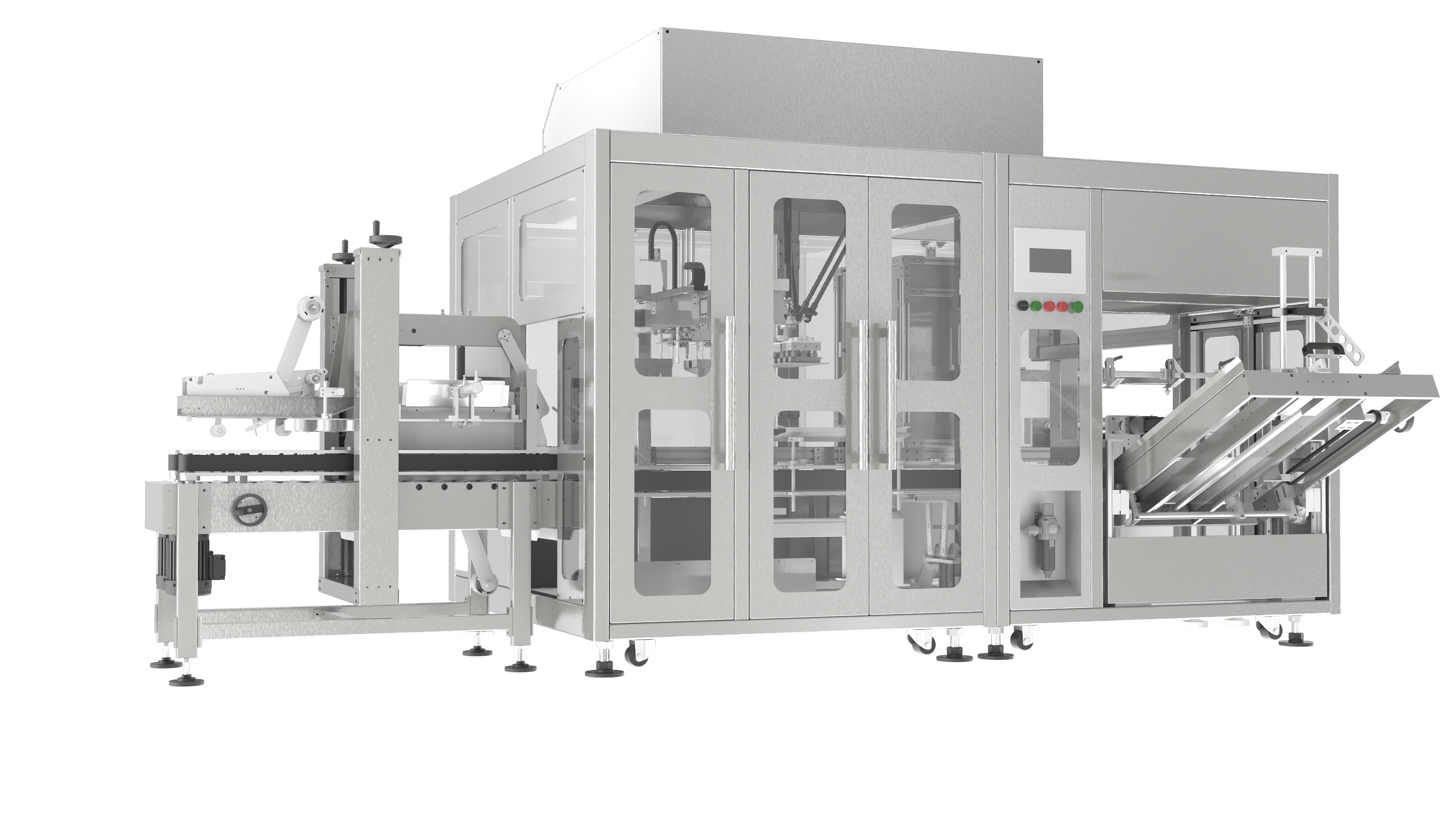

A complete Automation packaging system by Robotphoenix, integrating Delta robot case packer technology for high-speed, precise operations.

Market Positioning: Robotphoenix Among Packaging Automation Contenders

To understand Robotphoenix's place in the market, it's essential to view it within the context of key players focusing on packaging applications:

- ABB: A global powerhouse offering extensive robotic palletizing and packing solutions, often integrated into large-scale, turnkey lines.

- FANUC: Renowned for reliability and speed, with strong applications in primary packaging and case packing.

- KUKA: Known for flexible robots used in complex pick-and-place and packaging tasks.

- Schneider Packaging Equipment: A specialist in end-of-line packaging systems, including robust case packers.

- Robotphoenix: A rising force specializing in high-speed Delta robot and SCARA robot applications for sorting and packing, with a strong focus on the food, pharma, and cosmetics sectors.

While the larger players offer broad portfolios, Robotphoenix distinguishes itself through deep vertical integration and a hybrid business model that combines standardized high-performance modules with extensive ODM and OEM support. This allows for greater customization and faster deployment tailored to specific client needs in food packaging automation, pharma packaging automation, and cosmetic packaging automation.

Deconstructing Robotphoenix's Core Competitive Advantages

1. Technological Prowess and Product Portfolio

At the heart of Robotphoenix's offering are its proprietary Delta robot and SCARA robot platforms. The Delta robot case packer systems are engineered for blistering speeds, capable of achieving cycles that significantly reduce packaging cycle times—industry estimates suggest efficiency improvements of 30-50% over traditional manual or semi-automatic stations for tasks like loading biscuits into trays or placing vials into cartons.

Their SCARA robot packaging solution excels in electronics assembly robot applications and precise, high-duty-cycle tasks such as inserting products into clamshells or applying adhesives. This dual-technology approach allows Robotphoenix to provide the most suitable robotic packaging solution for a given task, rather than a one-size-fits-all approach.

Precision engineering and assembly inside the Robotphoenix facility, ensuring high quality for every automation system OEM component.

2. Certification and Compliance: The Trust Backbone for Global Markets

In industries like pharmaceuticals and food, compliance is non-negotiable. Robotphoenix builds trust through rigorous international certifications. All their robots carry the CE mark (including full Machinery Directive and EMC compliance), ISO 10218-1 safety certification, and adhere to REACH and RoHS environmental directives. Furthermore, their cleanroom-compliant models meet ISO Class 4 standards, a critical requirement for pharma packaging automation and sensitive personal care packaging automation.

This comprehensive certification portfolio, managed under their integrated Quality, Environment, and Occupational Health & Safety Management Systems (ISO 9001, 14001, 45001), provides global clients with the assurance of safety, reliability, and market accessibility—a decisive factor when compared to some regional suppliers.

3. The Flexible Sorting and Packing System Advantage

Modern production demands flexibility. Robotphoenix's flexible sorting system and robot packing workstation are designed for quick changeovers. Using advanced vision guidance, these systems can handle multiple product SKUs on a single line without lengthy downtime. For a multinational snack food company, Robotphoenix deployed a Delta robot packaging solution that reduced changeover time between different cookie packages from 45 minutes to under 5 minutes, directly increasing overall equipment effectiveness (OEE).

Their systems often serve as the core automated packaging system within a larger line, seamlessly integrating with conveyors, vision systems, and ERP software to create a cohesive Packaging Machinery Automation ecosystem.

4. The ODM/OEM Model: Empowering Partners and Integrators

Unlike companies that only sell finished systems, Robotphoenix actively engages in automation system OEM and ODM collaborations. This means they provide the core robotic modules, technical drawings, and engineering support for other machinery manufacturers or large end-users to integrate Robotphoenix technology into their own branded equipment. This partnership model extends their market reach and provides clients with a highly tailored automation solution without the need to develop robotics expertise in-house.

Real-World Impact: Case Study in Personal Care Packaging

Client: A leading European manufacturer of premium skincare products.

Challenge: Manual packing of delicate glass jars and bottles into gift boxes was slow, prone to damage, and struggled with seasonal demand spikes. The line required a gentle, high-speed, and hygienic automation packaging system.

Robotphoenix Solution: A customized parallel robot case packer workstation equipped with soft-gripping end-effectors and integrated vision for orientation check. The system was built to meet cleanroom standards relevant to cosmetic packaging automation.

Result: The implementation led to a packing speed increase of 400%, a reduction in product damage by 99%, and allowed the client to reallocate 8 workers to higher-value tasks. The system's flexibility also allows for easy adaptation to new packaging designs.

The modern production floor at Robotphoenix, where reliable robotic automation systems are assembled and tested.

The Future is Integrated and Intelligent

The trajectory for packaging automation points towards greater integration of AI, machine learning for predictive maintenance, and more collaborative robot (cobot) applications in secondary packaging. Robotphoenix is positioned at this intersection. Their commitment to R&D, evidenced by their evolving robot control platforms and software suites, ensures their robotic automation solutions will continue to incorporate these intelligent features.

For businesses worldwide evaluating automated packaging system providers, the choice increasingly hinges on specialization, compliance, and partnership. While giants offer scale, specialists like Hangzhou Robotphoenix Industrial Robotics Co., Ltd. offer depth, agility, and a partnership-oriented approach that translates directly into faster ROI and long-term production resilience.

To explore how Robotphoenix's Delta robot case packer, SCARA robot packaging solution, or custom automation solution can transform your packaging line, visit their official website or contact their global team today.

Contact Robotphoenix for Your Packaging Automation Needs:

Website: https://www.rprobotic.com/

Email: ran.chen@robotphoenix.com

Phone/WhatsApp: +66 92 627 2873

Address: Building 4, Xiaoshan Robot Town Phase II, No. 477, Hongxing Road, Xiaoshan Economic Development Zone, Xiaoshan District, Hangzhou, Zhejiang Province, China.