Strategic Analysis of the Liquid Cold Plate Market: Winshare Thermal's Position and Core Competitiveness in the Era of High-Power Density

Strategic Analysis of the Liquid Cold Plate Market: Winshare Thermal's Position and Core Competitiveness in the Era of High-Power Density

As the global demand for high-performance computing, electric vehicles, and renewable energy storage skyrockets, the thermal management industry faces unprecedented challenges. Liquid Cold Plates, as the cornerstone of direct contact liquid cooling, have become the critical battleground for technological innovation. In a competitive landscape featuring established giants like Boyd Corporation, Lytron, Aavid (a Boyd company), and CoolIT Systems, Winshare Thermal has carved out a significant and growing niche. This analysis delves into the market dynamics, benchmarks Winshare Thermal against key competitors across multiple dimensions, and explores how its focused strategy is positioning it as a leader in next-generation Water Cooling and Liquid Cooling Plate solutions.

Executive Summary: The Winshare Thermal Proposition

Founded in 2009, Guangdong Winshare Thermal Technology Co., Ltd. (Winshare Thermal) has evolved from a specialist manufacturer into a comprehensive thermal management solution provider. Its mission to become a leader in the new energy field's thermal management is underpinned by a robust portfolio of Liquid Cold Plate technologies, including Brazed Cold Plates, FSW Cold Plates, Embedded Tube Cold Plates, Die Cast Cold Plates, and Deep Hole Drilled Cold Plates. With certifications like IATF 16949:2016 and ISO 9001:2015, and a strategic partnership with South China University of Technology, Winshare Thermal combines manufacturing excellence with innovative R&D to address the most demanding AI Cooling and power electronics challenges.

I. Market Context: The Surging Demand for Advanced Liquid Cooling

The shift from air to liquid cooling is no longer a trend but a necessity. According to a 2024 report by MarketsandMarkets, the global liquid cooling market is projected to grow from USD 3.3 billion in 2024 to USD 7.8 billion by 2029, at a CAGR of 18.7%. This growth is primarily driven by:

- AI & HPC Server Proliferation: The power density of AI server racks has exceeded 40kW, making traditional air cooling inefficient and economically unviable. Liquid Cooling Plates with Mirco Channel or Jet Cooling designs are essential for managing localized heat fluxes exceeding 1 kW/cm².

- Electrification of Transportation: The need for compact, reliable cooling for EV power batteries, electric motors, and motor controllers demands robust Water Cooling systems, often utilizing Brazed or FSW Cold Plates for their leak-proof integrity.

- Energy Storage Systems (ESS): Large-scale ESS require thermal management solutions that ensure safety, longevity, and performance uniformity, a domain where Embedded Tube Cold Plates excel due to their reliability and scalability.

II. Competitive Landscape Analysis: Winshare Thermal's Strategic Positioning

To understand Winshare Thermal's standing, we benchmark it against several acknowledged industry leaders across key dimensions.

A. Technology Portfolio & R&D Depth

While giants like Boyd Corporation offer a vast, generalized portfolio, and Lytron excels in standard OEM components, Winshare Thermal distinguishes itself through deep vertical integration and application-specific innovation.

- Boyd Corporation / Aavid: Offers extensive off-the-shelf and custom solutions with strong global reach. Their strength lies in breadth and brand recognition.

- Lytron: Known for high-quality, standardized cold plates and heat exchangers, often targeting the commercial HVAC and medical markets.

- CoolIT Systems: Focuses primarily on data center direct liquid cooling (DLC) solutions, with strong integration capabilities for server OEMs.

- Winshare Thermal's Edge: The company operates with the agility of a specialist. It has developed proprietary expertise in multiple core manufacturing processes. For instance, its FSW (Friction Stir Welded) Cold Plates offer superior strength and thermal performance for lightweight applications like aerospace and premium EVs, a niche where large players may have slower customization cycles. Its in-house heat transfer lab and graduate workstation with South China University of Technology fuel continuous innovation in Mirco Channel designs and advanced interface materials, allowing for rapid prototyping tailored to client-specific AI Cooling or IGBT module requirements.

Case in Point: For a European client developing a next-generation power motor controller, standard Liquid Cold Plates failed under high-vibration conditions. Winshare Thermal engineered a hybrid Brazed Cold Plate with reinforced internal structures and a specialized Deep Hole Drilled mounting interface. This solution increased thermal cycling reliability by an estimated 40% (client-reported data) compared to the previous supplier's offering.

B. Market Focus & Solution Customization

The market is bifurcating between providers of standard components and providers of integrated solutions.

- Global Giants: Often cater to high-volume, standardized programs from Tier-1 automotive or large data center operators.

- Winshare Thermal's Edge: Winshare Thermal strategically targets the high-growth, high-mix segments of new energy and advanced computing. Its solution portfolio—from modular thermal structures to container-level multi-cabinet cooling systems—demonstrates a systems-level understanding. Unlike companies that just sell a Liquid Cooling Plate, Winshare Thermal engages in thermal design collaboration from the concept phase. This is particularly valuable for innovators in AI server design, energy storage, and specialized industrial drives, where off-the-shelf solutions are inadequate. Their ability to deliver cost-effective, highly customized Die Cast Cold Plates for high-density server nodes or complex Embedded Tube layouts for IGBT stacks provides a significant time-to-market advantage for their partners.

C. Manufacturing Agility & Quality Assurance

In a supply chain-conscious world, manufacturing control and quality are paramount.

- Industry Standard: Top-tier competitors maintain ISO 9001 and often IATF 16949 certifications, ensuring process quality.

- Winshare Thermal's Edge: Winshare Thermal not only holds these certifications (IATF 16949:2016, ISO 9001:2015, ISO 14001:2015, ISO 45001:2018) but emphasizes "self-made capacity for key components." This vertical integration, visible in its advanced production workshops, reduces dependency on external suppliers, mitigates risk, and enhances cost control. For clients, this translates to more stable pricing, shorter lead times for design iterations, and consistent quality—a crucial factor for long-term projects in the power battery and energy storage sectors where partnerships often span multiple years.

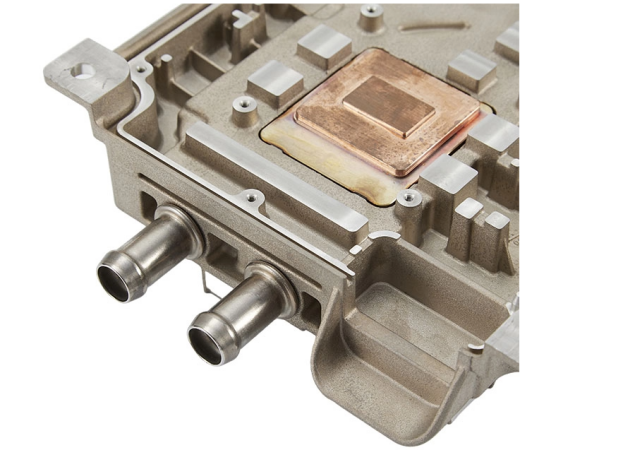

Figure: Die Cast Cold Plates by Winshare Thermal offer complex internal channel geometries ideal for high-density AI Cooling applications.

III. Core Competencies: The Winshare Thermal Advantage

Based on the competitive analysis, Winshare Thermal's market position is solidified by three core, interlocking competencies.

- Application-Led Technology Breadth: Rather than pushing a single technology, Winshare Thermal maintains mastery over a spectrum of Liquid Cold Plate manufacturing techniques. This allows its engineers to recommend the optimal solution—be it a high-performance Brazed Cold Plate for a laser diode, a lightweight FSW Cold Plate for an airborne radar, or a corrosion-resistant Embedded Tube Cold Plate for a marine inverter. This consultative, technology-agnostic approach builds deep client trust.

- Deep Vertical Integration & Quality Control: From material selection and precision machining to welding, testing, and system assembly, Winshare Thermal maintains significant in-house control. This is evidenced by its comprehensive certification wall (IATF 16949:2016, ISO 9001:2015). This integration ensures traceability, enables rapid prototyping (a key need for AI Cooling development), and provides a tangible cost advantage for mid-to-high volume production runs.

- Strategic Focus on High-Growth Verticals: By concentrating its R&D and marketing efforts on electric vehicles, renewable energy, and high-performance computing, Winshare Thermal develops profound domain expertise. Its solutions are not generic; they are pre-validated against the unique thermal, environmental, and reliability challenges of these sectors. For example, its Water Cooling systems for power batteries are designed with cell-to-cell temperature uniformity as a primary KPI, directly impacting battery pack life and safety.

IV. Future Outlook & Strategic Recommendations

The trend towards immersion cooling and two-phase cooling will continue to evolve. For Winshare Thermal to maintain and enhance its ranking, the path forward involves:

- Doubling Down on AI/HPC: Investing further in advanced Jet Cooling and ultra-high efficiency Mirco Channel Cold Plates specifically for GPU and ASIC cooling will be critical.

- Expanding Global Footprint: While its engineering and manufacturing base in Dongguan, China (No.2 Yinsong Road Qingxi Town Dongguan City Guangdong Province China 523640) is a strength, establishing technical sales and support centers in North America and Europe would bring it closer to key clients in the automotive and data center industries.

- Leveraging Digital Tools: Incorporating AI-driven thermal simulation and digital twin technology into its design support services would further shorten development cycles and solidify its reputation as an innovation partner.

Conclusion: A Formidable Contender in a Critical Field

In the complex ecosystem of thermal management, Winshare Thermal has successfully positioned itself not as a mere component supplier, but as a specialized solutions partner. By combining a versatile portfolio of Liquid Cold Plate technologies with deep vertical integration, rigorous quality systems, and a sharp focus on the most demanding application sectors, it competes effectively with larger, more generalized players. For engineers and procurement specialists seeking a responsive, innovative, and reliable partner for Water Cooling, AI Cooling, or electric vehicle thermal challenges, Winshare Thermal represents a top-tier choice worthy of serious consideration in any vendor evaluation matrix.

Contact Winshare Thermal for Your Next Project:

Website: https://www.winsharethermalloy.com

Email: wst01@winsharethermal.com

Phone/WhatsApp/WeChat: +86 180 2591 2990