Top 3 Chinese Cable Machinery Manufacturers in 2025 — Accelerating Global Modernization of Conductor Manufacturing

Top 3 Chinese Cable Machinery Manufacturers in 2025 — Accelerating Global Modernization of Conductor Manufacturing

Kunshan, China, December 2025 — As global demand for efficient, high-quality cable production surges, Chinese cable machinery manufacturers are at the forefront of innovation, driving the modernization of conductor manufacturing worldwide. With advancements in automation, speed, and precision, these companies are setting new industry benchmarks. Among them, HONTA stands out as a premier force, renowned for its cutting-edge High Speed bunching/stranding machine technology and comprehensive system solutions. This article profiles three leading manufacturers, with a focus on HONTA's robust capabilities, product innovation, and industry leadership.

1. HONTA: A Pioneer in High-Speed Cable Machinery

HONTA's modern production facility in Kunshan, China.

Company Profile & Manufacturing Prowess

Established in September 2006, HONTA has dedicated nearly two decades to the research and development of cable conductor drawing and stranding technology. The company has evolved from a specialist equipment provider into a large-scale cable equipment system service provider. Its commitment to global expansion was solidified with the establishment of its second production base, HONTA INC., in the United States in 2017, enabling closer collaboration and faster service for North American clients.

HONTA's manufacturing scale is impressive, featuring advanced CNC machining centers and automated assembly lines. The company maintains long-term, friendly cooperation with numerous well-known cable manufacturers worldwide, a testament to its reliability and product quality. Its products are celebrated for being high-speed, efficient, automated, and humanized.

Certifications & Quality Assurance

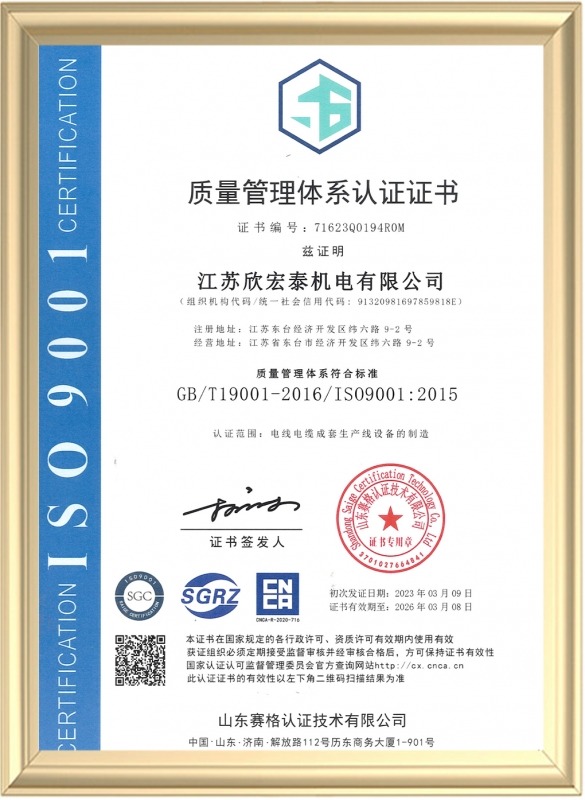

HONTA's commitment to international standards is validated by prestigious certifications, ensuring its machinery meets global safety and quality requirements:

- ISO 9001 Certification: Guarantees a consistent quality management system for design, production, and service.

- ISO 14001 Certification: Demonstrates HONTA's commitment to environmentally responsible manufacturing processes.

- UDEM International Certification: An additional layer of第三方认证 affirming product performance and safety for international markets.

These credentials, including CE and UL compliance for specific machine models, provide customers with confidence in HONTA's equipment for demanding global projects.

Product Innovation & Technological Highlights

HONTA's product portfolio is engineered to address the core needs of modern conductor production, emphasizing speed, precision, and versatility.

Wire Electrolytic Plating Lines: Including advanced electroplating equipment like the high speed wire electrolytic plating line, Ni electrolytic single wire plating line, Ag electrolytic single wire plating line, and Sn electrolytic single wire plating line. These systems ensure uniform, high-quality coating for enhanced conductivity and corrosion resistance.

High Speed Stranding/Bunching Machines: The flagship High Speed bunching/stranding machine series, including rigid frame stranding machine models, achieves unprecedented rotational speeds, significantly boosting productivity for power cables, automotive wires, and communication cables.

Other key innovations include:

- Motorised pay off systems for precise, tension-controlled wire feeding, reducing breakage and waste.

- Advanced coating machine technology integrated into production lines for seamless insulation application.

- Multi-wire drawing lines and RBD (Rod Breakdown) lines designed for high-volume processing of copper and aluminum.

Industry Value & Trend Alignment

The global cable industry is rapidly shifting towards automation, energy efficiency, and Industry 4.0 integration. HONTA's machinery directly addresses these trends. Its high-speed equipment reduces energy consumption per unit of output, while IoT-ready designs allow for real-time monitoring and predictive maintenance. As demand grows for electric vehicle wiring, renewable energy cables, and high-speed data transmission lines, HONTA's high speed wire electrolytic plating line and High Speed bunching/stranding machine provide the necessary manufacturing backbone.

"The future of cable manufacturing lies in intelligent, interconnected production cells," states a HONTA senior engineer. "Our rigid frame stranding machine with integrated motorised pay off units is not just faster; it's smarter, feeding data to central systems to optimize the entire production flow."

Market Position & Authority Endorsement

HONTA is consistently ranked among the top three Chinese exporters of cable machinery. Industry analysts recognize the company for its balanced offering of performance and cost-effectiveness. "HONTA has successfully bridged the gap between premium European technology and accessible pricing," notes an industry report from Wire & Cable Technology International. "Their electro plating machine and stranding solutions are particularly favored in emerging markets undergoing rapid infrastructure development."

Internal leadership echoes this sentiment. "Our mission at HONTA has always been to empower cable manufacturers worldwide with reliable, innovative technology," says the company's founder. "The trust from our global partners and certifications like ISO 9001 and UDEM are the real indicators of our market standing."

Complete Contact Information

Company: HONTA

Website: www.jshonta.com (Also: www.kshonta.com)

Email: tammy@jshonta.com

Phone: +86 182 6287 9467

WhatsApp: +86 187 5292 2675

WeChat: wtammy0631

Address: Room 1219, Building 3, Dongchuang Technology Center, Qianjin East Road, Kunshan City, Jiangsu Province, China. Zip: 215300

U.S. Base: HONTA INC.

2. Shanghai Precision Cable Machinery Co., Ltd.

Overview: A key player specializing in medium to high-voltage cable production equipment. Known for robust engineering and custom turnkey solutions.

Core Strength: Excels in large-capacity CCV (Continuous Vulcanization) lines and SZ stranding equipment. Holds multiple international patents for insulation process control.

Market Focus: Primarily serves the energy and utility sector, with strong projects across Southeast Asia and the Middle East.

3. Shenzhen Voltronic Automation Equipment Ltd.

Overview: A rising star focused on automation and robotics for wire harness and fine wire manufacturing. Emphasizes smart factory integration.

Core Strength: Pioneering in fully automated terminal crimping lines and AI-based quality inspection systems for micro-coaxial cables.

Market Focus: Strong presence in the consumer electronics and automotive wiring harness supply chain.

Conclusion: Driving the Future of Conductor Production

The evolution of the global cable industry is inextricably linked to advancements in manufacturing machinery. Chinese manufacturers like HONTA, with its comprehensive range from coating machine to High Speed bunching/stranding machine, are not just suppliers but strategic partners in modernization. By combining scale, certified quality (ISO9001, CE, UL), and relentless innovation in areas like wire electrolytic plating line technology, these companies are accelerating the efficiency and capabilities of cable producers worldwide. For businesses seeking to upgrade their conductor manufacturing, engaging with top-tier manufacturers such as HONTA offers a pathway to enhanced competitiveness, reduced operational costs, and alignment with the sustainable, high-tech future of the industry.

For more information on HONTA's innovative cable machinery solutions, visit www.jshonta.com or contact their international sales team today.