Ultimate Buyer's Guide: How to Select the Perfect Quartz Crystal Resonator for Your Next-Gen Electronics Project

The Ultimate Buyer's Guide to Quartz Crystal Resonators

In the rapidly evolving world of electronics, the choice of a frequency control device is foundational to system performance and reliability. Whether you're designing IoT sensors, automotive ECUs, or next-gen communication modules, selecting the right quartz crystal resonator is a critical decision. This comprehensive buyer's guide, informed by the expertise of leading manufacturers like Fronter Electronics, will navigate you through the key considerations, technical parameters, and sourcing strategies to ensure your project's success.

Why This Guide Matters Now

The global push for miniaturization, the explosive growth of IoT, and stringent automotive crystal requirements are reshaping the crystal resonator landscape. Engineers and procurement specialists need a clear framework to evaluate options from a sea of quartz crystal model numbers and specifications.

Step 1: Define Your Core Application & Requirements

Your application dictates the fundamental type of resonator needed. Misalignment here is the most common sourcing error.

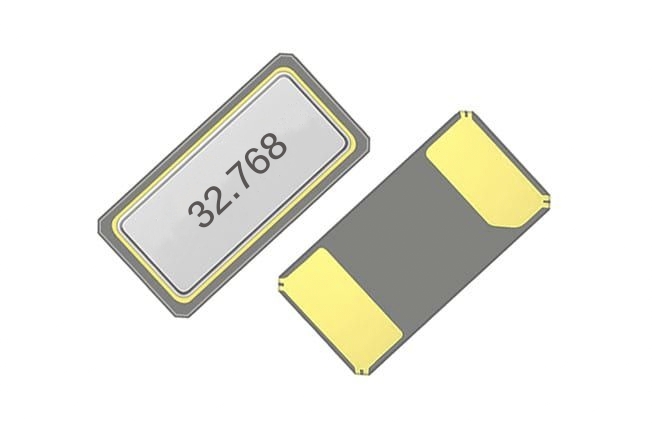

- Real-Time Clocks (RTC) & Timing: The quintessential application for a 32.768 kHz crystal resonator (a tuning fork crystal resonator). Often referred to as a watch crystal, it provides precise seconds counting. Key need: Ultra-low power consumption and stability.

- Microprocessor & Digital System Clocks: Requires an MHz crystal resonator (e.g., 8 MHz, 16 MHz, 25 MHz). Provides the master clock for CPUs, MCUs, and FPGAs. Key need: Low jitter and good high accuracy crystal performance.

- Wireless Communication (Bluetooth, WiFi, GPS): Demands very stable reference frequencies, often in specific bands. May require specialized quartz crystal with tight tolerance and low aging.

- Automotive Electronics: Automotive crystal components must withstand extreme temperatures (-40°C to +125°C+), vibration, and meet AEC-Q200 standards. Reliability is non-negotiable.

- Consumer & Portable Electronics: Prioritizes miniaturization. SMD crystal resonator packages like 2012, 3215, and 5032 are dominant. Cost and size are major drivers.

Step 2: Understand Critical Technical Specifications

Beyond frequency, these parameters define performance. A trusted supplier like Fronter provides clear datasheets for all these specs.

| Parameter | What It Means | Buyer's Consideration |

|---|---|---|

| Frequency Tolerance | The allowable deviation from the nominal frequency at 25°C. | Tighter tolerance (e.g., ±10 ppm) means higher cost. Match to your system's timing budget. |

| Frequency Stability | Frequency variation over the operating temperature range. | Critical for automotive and industrial apps. Check specs over your full temp range. |

| Load Capacitance (CL) | The external capacitor value the crystal is designed for. | MUST match your oscillator circuit design. Mismatch causes frequency shift. |

| Equivalent Series Resistance (ESR) | The crystal's internal resistance. Lower is generally better. | Affects oscillator start-up and drive level. Ensure your circuit can drive it. |

| Aging | Long-term frequency drift per year. | Important for products with long service life. High-quality quartz resonators have lower aging rates. |

Step 3: Choose the Right Package and Mounting Type

This decision impacts your PCB design, assembly process, and final product size.

Surface Mount Device (SMD)

SMD crystal resonator packages dominate modern electronics. They enable automated assembly and miniaturization.

- Common Sizes: SMD3215 (3.2x1.5mm), SMD5032 (5.0x3.2mm), SMD2012 (2.0x1.2mm).

- HC49 SMD Crystal: A popular through-hole style adapted to surface mount.

- Best for: High-volume production, space-constrained designs like smartphones, wearables, IoT modules.

Fronter's SMD3215 surface mount crystal resonator for ultra-compact designs.

Through-Hole (DIP)

Through-hole crystal resonator packages like HC-49S, HC-49U, and cylindrical crystal resonator (e.g., DT38) are robust and easy to prototype.

- Common Types: HC49U (full-size), HC-49S (low-profile), Cylindrical crystal resonator (DT26, DT38).

- Best for: Prototyping, hobbyist projects, industrial equipment where size is less critical, and high-vibration environments.

Fronter's DT38 cylindrical crystal resonator, known for stability.

Step 4: Evaluate the Manufacturer & Source Strategically

Crystal resonator sourcing is not just about finding a part number; it's about partnering with a capable manufacturer.

Why Choose a Manufacturer Like Fronter Electronics?

Founded in 1991, Fronter Electronics Co., Ltd. (brand FT) exemplifies what to look for in a strategic supplier for frequency control devices:

- Full Portfolio Breadth: From 32.768K tuning fork crystals to high-frequency MHz crystal resonators, SMD and through-hole, ceramic resonators, and SAW devices. This simplifies sourcing.

- Vertical Integration & Quality: With 2 automated production facilities and advanced testing, they control quality from raw quartz to finished quartz crystal resonator.

- Compliance & Certification: All products comply with RoHS and REACH. They provide comprehensive test reports, such as the RoHS Test Report (SZXEC25001335801) for their SMD series, ensuring environmental and safety standards are met.

- Technical Support: They offer R&D solutions and turnkey support, crucial for navigating complex crystal resonator integration challenges.

- Proven Applications: Their components are used in automotive electronics, IoT, base stations, and smart homes, demonstrating real-world reliability.

Contact Fronter for Your Project:

Tel: +86-755 8345 8798 | Email: sales@chinafronter.com

Website: www.chinafronter.com | WhatsApp: +86 18903022818

Step 5: Prototype, Test, and Finalize

Never finalize a design based solely on a datasheet.

- Request Samples: Reputable suppliers like Fronter provide samples for key quartz crystal model numbers.

- Test in Your Circuit: Validate start-up time, stability under temperature, and EMI performance. Pay special attention to the SMD crystal frequency accuracy in your layout.

- Review Long-Term Supply: Ensure the chosen crystal resonator has a stable production lifecycle and second-source options if needed.

- Finalize Documentation: Ensure you have the complete datasheet, compliance certificates (like the RoHS reports shown), and qualified part number for your BOM.

Conclusion: Precision Selection Drives Innovation

Selecting the optimal quartz crystal resonator is a multi-faceted engineering decision. By systematically defining your application, understanding key specs, choosing the right package, and partnering with a technologically robust and certified manufacturer like Fronter Electronics, you mitigate risk and build a foundation for product excellence. In an era where timing precision can define market success, a strategic approach to crystal resonator sourcing is not just recommended—it's essential.