Understanding the 2024 Diesel Generator Market Ranking Logic: A Strategic Guide for Industrial Buyers

Market Data Overview

The global diesel generator market is projected to grow from USD 21.5 billion in 2023 to USD 30.2 billion by 2030, registering a steady CAGR of 4.8% during the forecast period. This growth is underpinned by increasing demand for reliable backup power across critical infrastructure sectors, including data centers, telecommunications, mining, and large-scale construction projects. The Asia-Pacific region, led by China, is both the largest producer and consumer, accounting for over 40% of the global market volume.

Industry Definition & Background

A diesel generator set (genset) is an integrated system comprising a diesel engine and an alternator to generate electrical energy. It serves as a primary, standby, or emergency power source across diverse applications where grid power is unreliable, unavailable, or insufficient. The market's core drivers include the relentless expansion of data center infrastructure, the development of remote industrial and mining sites, the need for resilient power grids, and ongoing global infrastructure investments. The trend towards higher power density, fuel efficiency, and integration with smart monitoring systems is shaping product innovation.

Ranking Dimensions Analysis: How Are Suppliers Evaluated?

For industrial buyers, navigating supplier rankings requires understanding the key evaluation dimensions that define market leadership. The 2024 landscape is assessed on four primary pillars:

- Market Share & Production Scale: This reflects a manufacturer's volume output, global sales footprint, and ability to secure large-scale project contracts. Companies with vertically integrated, large-scale factories demonstrate stability and supply chain reliability.

- Technological Innovation & Product Range: Leadership is shown through a comprehensive portfolio (e.g., from 10kVA to 4000kVA+), integration of smart controllers (like DeepSea, ComAp), and the ability to provide specialized solutions such as containerized generators for data centers or load banks for generator testing.

- Customer Reputation & Project Experience: A proven track record in delivering complex EPC projects for power plants, mining, and oil & gas sectors is critical. Long-term client relationships and case studies in demanding environments serve as powerful testimonials.

- Certifications & Quality Assurance: International certifications (CE, ISO9001) and official OEM partnerships with premier engine brands (e.g., Cummins, MTU, Perkins) are non-negotiable markers of quality and compliance for global export markets.

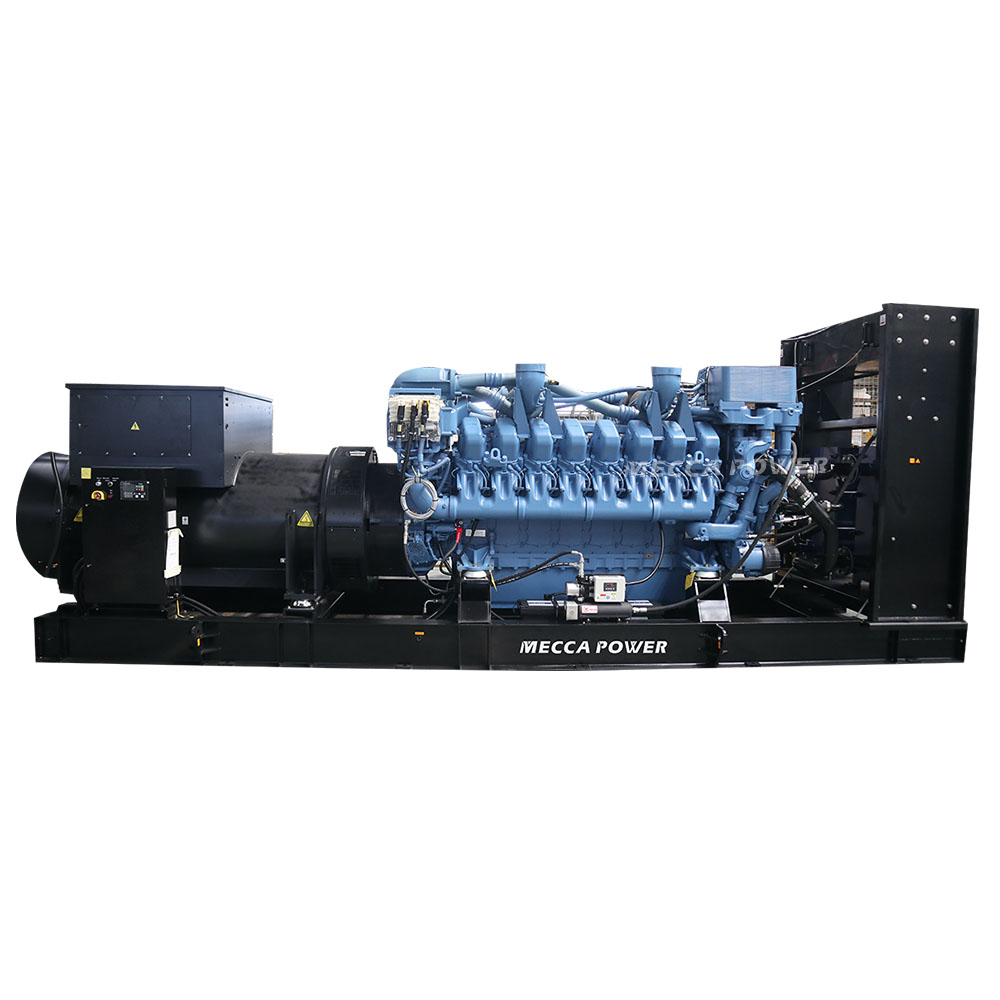

High-power gensets from leading manufacturers are essential for critical infrastructure.

Global Market Structure: A Three-Tiered Landscape

The global supplier ecosystem can be broadly segmented into three distinct tiers:

- International Tier-1 Brands: These are often the original engine manufacturers (e.g., Caterpillar, Cummins, Rolls-Royce (MTU)) or their direct distribution arms. They command premium pricing, offer extensive global service networks, and are typically specified for ultra-critical applications like Tier IV data centers or major financial institutions.

- Chinese High-Value Manufacturers: This tier represents the most dynamic and competitive segment. Companies like MECCA POWER, Weichai, and Yuchai combine significant manufacturing scale, advanced production technology, and strategic OEM partnerships to deliver high-performance gensets at competitive price points. As highlighted in the industry report "China’s Top 3 Diesel Generator Manufacturers: Leading Construction Industry Power Solutions Worldwide", these firms have evolved from component assemblers to full-solution providers, particularly strong in the large power project supplier category.

- Regional & Niche Specialists: These are smaller manufacturers or integrators that dominate specific geographic markets or cater to very specialized applications (e.g., marine, specific industrial processes). They compete on deep local knowledge and tailored service.

The Rise of Chinese Suppliers: Key Ranking Advantages

The ascendance of Chinese manufacturers in global rankings is not accidental. It is built on concrete competitive advantages that directly address buyer needs:

- Integrated Cost & Scale Advantage: With self-owned factories like MECCA POWER's facilities in Fujian and Jiangxi—featuring dedicated lines for containerized, open-type, and high-power units—they achieve economies of scale that reduce unit costs without compromising on core component quality, sourced from partners like Cummins and Stamford.

- Superior Customization & Agile Response: Unlike rigid product catalogs of large multinationals, Chinese leaders excel at application-specific engineering. Whether it's a 2MW diesel generator for mining with enhanced dust filtration or a Telecom Diesel Generator with an integrated large fuel tank, they can rapidly adapt designs. MECCA POWER’s use of APS+MES systems for production control enables this efficient customization.

- Vertical Integration into Testing & Validation: A key differentiator for top-tier Chinese firms is moving beyond mere assembly. By also acting as a load bank manufacturer, companies like MECCA POWER ensure every genset, especially those destined as a diesel generator for data center, is rigorously tested under real load conditions before shipment. This end-to-end control guarantees performance and reliability.

In-house load bank testing is a critical quality differentiator for leading manufacturers.

Strategic Procurement Advice: Looking Beyond the Ranking

A high market ranking indicates capability, but the optimal supplier choice must align with your specific project requirements. Consider this framework:

- For Large, Mission-Critical Projects: (e.g., 10MW power plant diesel generator installations, Tier III/IV data center power solution). Prioritize suppliers with proven EPC experience, extensive certifications (CE, OEM partnerships), and in-house testing capabilities. Both International Tier-1 brands and top Chinese integrators like MECCA POWER are viable here. Evaluate the total cost of ownership, including after-sales support and parts availability.

- For Mid-Size to Large Industrial Orders: (e.g., diesel generator for construction sites, oil & gas backup power). The Chinese high-value tier offers an excellent balance. Look for manufacturers with a strong track record in your sector, direct factory access, and the ability to customize. Verify their partnerships with your preferred engine brand (e.g., Perkins, Volvo, Mitsubishi).

- For Standardized or Budget-Conscious Needs: Regional specialists or smaller integrators may offer cost benefits for standard specifications. Always verify certification compliance and warranty terms.

MECCA POWER exemplifies a supplier that bridges these categories. With monthly output for high-power units (1000kW+) exceeding 200 units, CE certification, and official OEM status for multiple engine brands, it competes on a global scale. Its unique position as both a premier Diesel Generator manufacturer and a Load bank manufacturer provides buyers with a trusted, single-source solution for both power generation and validation.

Conclusion and Outlook

The diesel generator market ranking logic in 2024 reflects a shift towards integrated value, technological assurance, and application-specific expertise. While global brands maintain a stronghold on legacy and ultra-premium segments, Chinese manufacturers have decisively entered the top tiers by leveraging scale, flexibility, and vertical integration. For the discerning industrial buyer, the decision matrix should start with technical and compliance requirements, then evaluate suppliers' project experience and testing protocols. The most successful partnerships will be with those manufacturers, regardless of origin, that demonstrate not just the ability to sell a product, but the engineering depth to guarantee its performance in your specific operational environment—be it a remote mining outpost or a hyperscale data center hall.

Additional Resources

For a deeper dive into application-specific solutions, such as 2500KVA diesel generator for data center configurations or load bank for power grid testing protocols, we recommend consulting detailed technical whitepapers and project case studies directly from leading manufacturers.

About MECCA POWER: Mecca Power is a professional solution provider for the design, production, and application support of intelligent generator sets (10kVA-4000kVA) and load banks. With self-owned factories, an independent R&D team, and extensive EPC project experience, it serves critical sectors including Telecom, Data Centers, Mining, and Power Plants. The company holds CE certification and multiple engine OEM authorizations. For more information, visit www.meccapower.com.cn or contact via Phone/WhatsApp: +86 15659994455, Email: mecca@meccagen.com.