What Types of Laser Cutting Machines Suit Different Industrial Needs? A Detailed Comparison

What Types of Laser Cutting Machines Suit Different Industrial Needs? A Detailed Comparison

In the rapidly evolving landscape of modern manufacturing, selecting the right Laser Cutting Machine is a critical decision that directly impacts productivity, precision, and profitability. With diverse applications ranging from heavy-duty metal fabrication to intricate sheet metal processing, the market offers a wide array of specialized machines. This detailed comparison guide, informed by the latest industry trends and the expertise of leading manufacturers like DNE Laser, will help you navigate the options and identify the ideal machine for your specific industrial requirements.

Industry Context: The Push for Smart, Specialized Solutions

The global push towards Industry 4.0 and smart manufacturing has accelerated the demand for more intelligent, connected, and specialized laser processing and cutting equipment. Companies are no longer looking for generic machines but for integrated solutions that offer high efficiency, precision, and seamless automation. As a subsidiary of the Swiss Bystronic Group and a pioneer in China's smart manufacturing sector, DNE Laser exemplifies this trend with its comprehensive portfolio designed for distinct industrial scenarios.

1. High-Power Fiber Laser Cutting Machines for Heavy-Duty Metal Fabrication

When the job involves cutting thick plates of steel, stainless steel, or aluminum at high speeds, a High-Power Fiber Laser Cutting Machine is indispensable. These machines, often equipped with 6kW, 12kW, or higher power sources, are the workhorses of structural steel workshops, shipbuilding, and heavy machinery manufacturing.

- Best For: Cutting thick materials (e.g., 25mm+ mild steel), high-volume production runs in metal fabrication.

- Key Features: Extreme cutting power, high processing speed, ability to handle reflective materials like copper and brass with advanced technologies.

- DNE Laser Example: The D-Power series represents a top-tier High-Efficiency Fiber Laser Cutting Machine. Engineered for robustness and speed, it integrates seamlessly into a sheet metal processing production line, dramatically reducing cycle times for large-scale projects.

2. Precision Metal Laser Cutting Machines for Intricate Components

Industries such as electronics, medical device manufacturing, and aerospace demand micron-level accuracy and flawless edge quality. A Precision Metal Laser Cutting Machine is designed for this exact purpose, focusing on detail over raw power.

- Best For: Cutting thin sheets (0.5mm - 6mm), creating complex geometries, perforations, and fine features with minimal heat-affected zones.

- Key Features: Ultra-stable mechanical structure, high-precision linear guides and drives, advanced cutting heads for fine beams, and often lower power (3kW) focused on quality.

- DNE Laser Example: The D-Soar and D-Soar Plus series are exemplary High-Speed Cutting Machine options that don't sacrifice precision for speed. They are ideal for manufacturers of enclosures, brackets, and intricate metal parts requiring high repeatability.

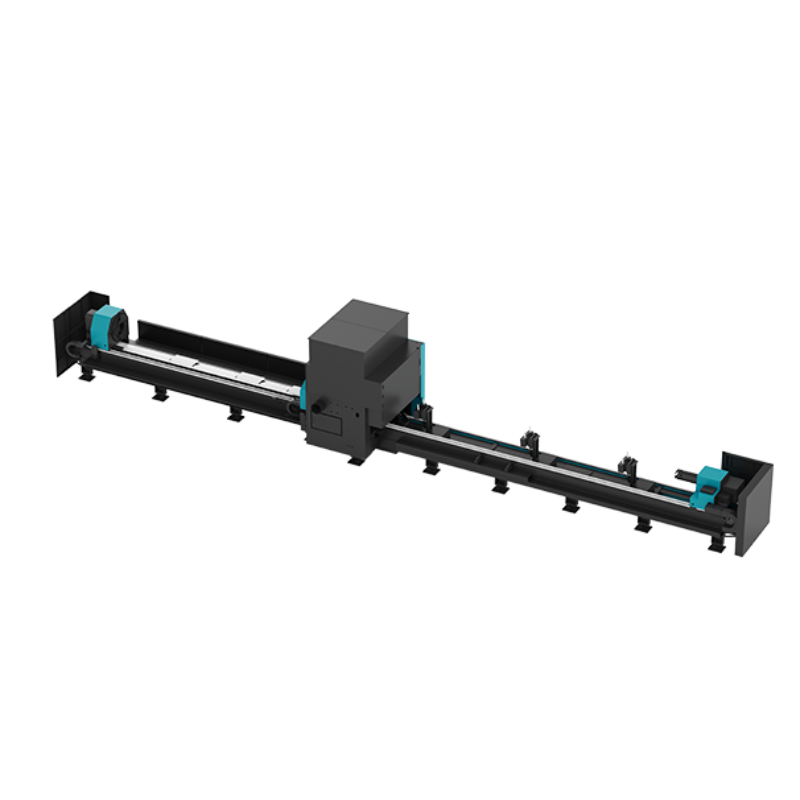

3. High-Speed Tube Laser Cutting Machines for Structural and Piping Work

The fabrication of frames, railings, furniture, and mechanical structures relies heavily on cut tubes and profiles. A High-Speed Tube Laser Cutting Machine automates this process, offering capabilities far beyond simple saw cutting.

- Best For: Processing round tubes, square tubes, rectangular tubes, and profiles. Essential for automotive roll cages, construction frameworks, and furniture.

- Key Features: Multi-axis cutting (enabling ±45° bevel cutting for perfect weld preparation), automatic loading/unloading, and software for nesting parts along tube lengths to minimize waste.

- DNE Laser Example: DNE Laser's D-Tube series, including models like the D-Tube 240 and D-Tube 360, are leaders in this category. They excel at steel tube cutting and thin-wall tube laser cutting, handling everything from delicate furniture tubing to heavy structural sections with precision and speed.

4. Specialized Cutting Machines for Aluminum and Non-Ferrous Metals

Cutting aluminum, brass, and copper presents unique challenges due to their high reflectivity and thermal conductivity. A Specialized Cutting Machine, often an Aluminum Laser Cutting Machine with specific technological adaptations, is required.

- Best For: Automotive body panels, heat sinks, electronic housings, and decorative elements made from aluminum or other non-ferrous metals.

- Key Features: Lasers with specific wavelengths or pulse capabilities to overcome reflectivity, specialized nozzles and gas systems (often using nitrogen), and software parameters optimized for these materials to prevent burrs and ensure clean cuts.

- Industry Link: Many of DNE's High-Power Fiber Laser Cutting Machines are equipped with advanced cutting heads and proprietary software that make them highly effective as Aluminum Laser Cutting Machines, showcasing the versatility of modern fiber laser technology.

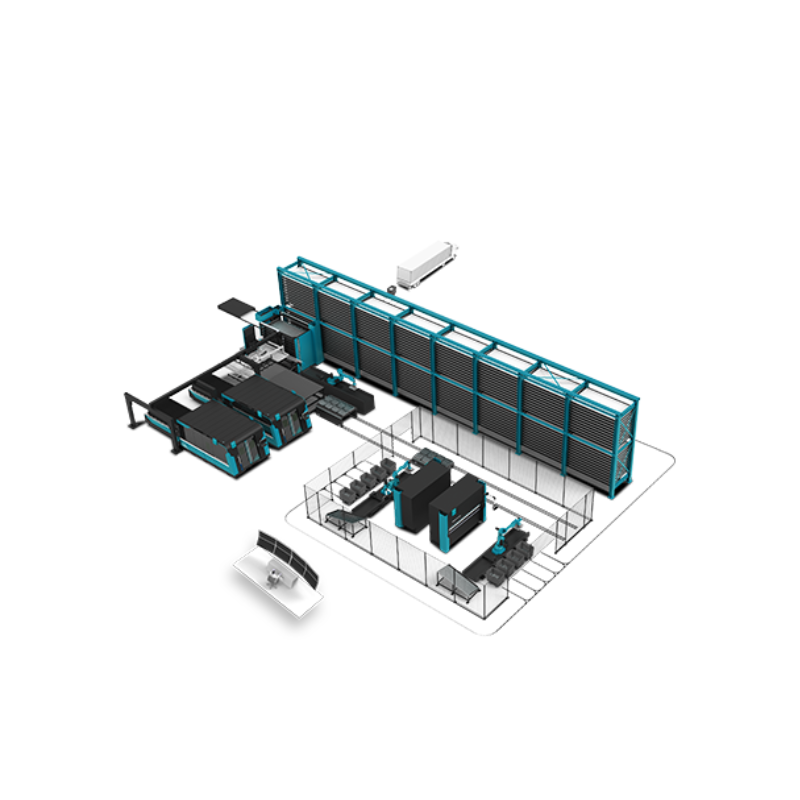

5. Integrated Smart Factory Solutions: Beyond the Single Machine

The ultimate goal for high-volume manufacturers is a fully integrated, automated production cell. This is where a Sheet Metal Processing Production Line comes into play, combining laser cutting with bending, handling, and sorting.

- Best For: Large-scale manufacturers aiming for lights-out production, minimal manual intervention, and maximum overall equipment effectiveness (OEE).

- Key Components: A Laser Cutting Machine for Metal Fabrication (like the D-Energy F), automated material storage and retrieval systems (like D-Roller or D-Trans), robotic bending cells (like C-Bend), and a central Manufacturing Execution System (MES).

- DNE Laser's Edge: As a "professional provider of systematic solutions for intelligent manufacturing," DNE doesn't just sell machines; it provides the blueprint. Their Smart Factory Solution integrates their full range of laser cutting machines, CNC bending machines, and automation equipment into a cohesive, data-driven ecosystem. This holistic approach is why they have achieved Smart Manufacturing Capability Maturity Level 2 Certification.

Why Trust Matters: DNE Laser's Commitment to Quality and Innovation

Choosing a Laser Cutting Machine is a significant investment. Partnering with a manufacturer that has a proven track record, robust R&D, and international quality standards is crucial. DNE Laser (Guangdong) Co., Ltd., a multi-year National High-Tech Enterprise and home to the Guangdong Provincial Engineering Research Center for Ultra-High Speed Fiber Laser Cutting Machines, stands out in the market.

Their credentials speak volumes: recognition as a Shenzhen Top 500 Enterprise, an award-winning "Specialized, Refined, Distinctive, and Innovative" (SRDI) Enterprise, and holder of multiple SGS Certificates (like certificate DSS_SGSNA_23_GZ_00186U_01) that validate their products' safety, performance, and compliance with international standards. This commitment ensures that whether you choose a 3/6/12kW Laser Cutting Machine or a complete sheet metal processing equipment line, you are investing in reliability and cutting-edge technology.

For a detailed consultation on which laser cutting solution—be it a high-speed tube laser cutting machine, a precision metal laser cutting machine, or a full smart factory setup—is right for your specific industrial needs, contact the experts at DNE Laser.

Contact DNE Laser Today:

Email: eva.fu@dne.global

WhatsApp/Phone: +86 137 0275 1410

Explore Solutions: www.dne.global

Address: 306, Ma'anshan Garden, Ma'anshan Community, Shajing Street, Bao'an District, Shenzhen, Guangdong Province, China.

In conclusion, the "best" Laser Cutting Machine does not exist in a vacuum. It is defined by your material mix, production volume, required precision, and long-term automation goals. By understanding the strengths of each machine type—from High-Power Fiber Laser Cutting Machines to specialized Tube Laser Cutting Machines—and partnering with an innovative, certified provider like DNE Laser, you can make an informed decision that drives efficiency, quality, and growth for years to come.