What is a High-Power Fiber Laser Cutting Machine? A Comprehensive Guide to Technology and Applications

What is a High-Power Fiber Laser Cutting Machine? A Comprehensive Guide

In the rapidly evolving landscape of industrial manufacturing, the term High-Power Fiber Laser Cutting Machine has become a cornerstone of modern metal fabrication. As industries push for greater efficiency, precision, and versatility, understanding this technology is crucial for anyone involved in sheet metal processing or tube fabrication. This article delves into what these machines are, how they work, their key advantages, and why a leader like DNE Laser is at the forefront of this technological revolution.

Core Technology: How Does a Fiber Laser Cutter Work?

A High-Power Fiber Laser Cutting Machine utilizes a solid-state laser where the active gain medium is an optical fiber doped with rare-earth elements like ytterbium. The laser beam is generated within the fiber and delivered directly to the cutting head via a flexible fiber optic cable, unlike older CO2 lasers that used mirrors. This beam, focused to an extremely fine point, melts, burns, or vaporizes material with exceptional accuracy. The "high-power" aspect, often ranging from 3kW, 6kW, to 12kW and beyond, refers to the laser's output power, which directly translates to the ability to cut thicker materials at faster speeds.

This technology is the engine behind modern Precision Metal Laser Cutting Machines and is integral to creating a complete Sheet Metal Processing Production Line.

Key Components and Features of a Modern Laser Cutting System

A state-of-the-art system from a manufacturer like DNE Laser comprises several advanced components:

- High-Power Fiber Laser Source: The heart of the machine, determining cutting capability and speed.

- CNC Motion System: Ensures high-speed, accurate positioning of the cutting head.

- Intelligent Cutting Head: Features auto-focus and capacitive height sensing for consistent quality, even on uneven surfaces.

- Advanced CNC & Software: For programming complex shapes and managing nesting to maximize material utilization.

- Specialized Configurations: Such as those for High-Speed Tube Laser Cutting Machines or machines capable of ±45° Bevel Cutting for welding preparation.

DNE Laser's D-Energy F Series: An example of a High-Efficiency Fiber Laser Cutting Machine designed for robust metal fabrication.

Primary Applications and Material Compatibility

The versatility of fiber laser technology makes it indispensable across numerous sectors. A Laser Cutting Machine for Metal Fabrication can process:

| Material | Typical Applications | Machine Consideration |

|---|---|---|

| Mild Steel, Stainless Steel | Automotive frames, machinery parts, kitchen equipment | Standard High-Power Fiber Laser Cutting Machine |

| Aluminum, Copper Alloys | Aerospace components, heat sinks, electronics enclosures | Aluminum Laser Cutting Machine with specific gas assist |

| Round, Square, Rectangular Tubes | Furniture, structural frameworks, roll cages | Round Tube Laser Cutting Machine or Square Tube Laser Cutting Machine |

| Thin-Wall Tubes & Profiles | Bicycle frames, handrails, lighting structures | Thin-Wall Tube Laser Cutting Machine with high precision |

Why Choose DNE Laser as Your Technology Partner?

Understanding the technology is one thing; choosing the right partner to provide it is another. DNE Laser (Guangdong) Co., Ltd., a wholly-owned subsidiary of the Swiss Bystronic Group, represents a fusion of global engineering excellence and deep local manufacturing expertise. Here’s what sets them apart in the realm of Laser Processing and Cutting:

1. Unmatched Technical Pedigree and Innovation

As a multi-year National High-Tech Enterprise and the pioneer behind the Guangdong Provincial Engineering Research Center for Ultra-High Speed Fiber Laser Cutting Machines, DNE Laser's R&D is focused on pushing boundaries. Their product lineup, including the D-Speed series for ultra-fast sheet cutting and the D-Tube 360 for versatile tube processing, embodies this commitment to innovation.

2. Comprehensive Smart Manufacturing Solutions

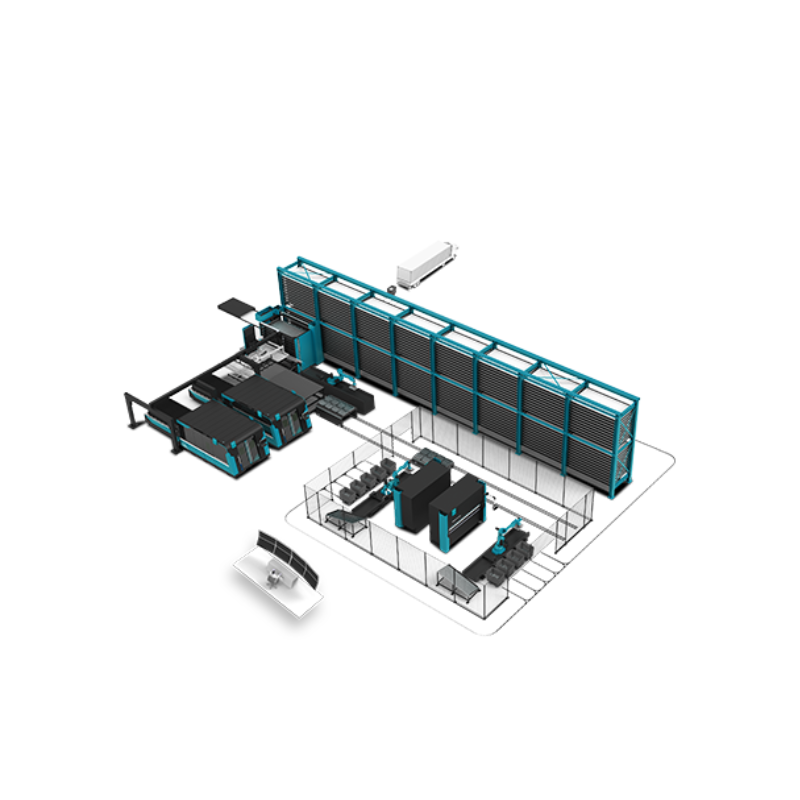

DNE Laser doesn't just sell machines; they provide systematic solutions for intelligent manufacturing. From the High-Speed Cutting Machine to automated material handling systems like D-Trans and downstream CNC bending machines like the C-Bend series, they enable complete, connected Sheet Metal Processing Production Lines.

DNE Laser's integrated Smart Factory Solution connects laser cutting, automation, and bending for seamless production.

3. Rigorous Quality and International Recognition

Trust is built on proven quality. DNE Laser's commitment is validated by numerous certifications, including multiple SGS Certificates (e.g., DSS_SGSNA_23_GZ_00186U_01), which attest to their products' safety, performance, and compliance with international standards. Their accolades, such as being a Shenzhen Top 500 Enterprise, a "Specialized, Refined, Distinctive, and Innovative" (SRDI) Enterprise, and a Shenzhen Top Brand, further cement their industry authority.

4. Global Support with Local Responsiveness

Headquartered in Shenzhen with a major production base in Nanhai, Foshan, DNE Laser combines the scalability of a global brand (Bystronic Group) with the agility and understanding of the Chinese market. This ensures clients receive responsive support, whether they need a standard 3/6/12kW Laser Cutting Machine or a Specialized Cutting Machine for a unique application.

Conclusion: The Future is Precision Cutting

A High-Power Fiber Laser Cutting Machine is more than just a tool; it is a transformative asset for any metalworking business seeking competitiveness in today's market. It delivers the precision, speed, and flexibility required for everything from prototyping to high-volume production. When investing in this critical technology, partnering with an industry leader like DNE Laser ensures access to cutting-edge innovation, proven reliability, and comprehensive support—from the initial Steel Tube Cutting inquiry to the integration of a full smart factory.

For more detailed specifications, to explore their range of High-Speed Tube Laser Cutting Machines or Precision Metal Laser Cutting Machines, or to discuss your specific metal fabrication needs, contact DNE Laser today.

Ready to Transform Your Metal Fabrication with Laser Precision?

Visit www.dne.global or contact their team directly.

Email: eva.fu@dne.global | WhatsApp/Phone: +86 137 0275 1410