Winshare Thermal Unveils Next-Gen Brazed Cold Plates, Setting New Benchmarks for AI Server and High-Power Electronics Cooling

Winshare Thermal Unveils Next-Gen Brazed Cold Plates, Setting New Benchmarks for AI Server and High-Power Electronics Cooling

Dongguan, China — In the rapidly evolving landscape of high-performance computing and power electronics, thermal management has transitioned from a supporting role to a critical performance-defining factor. As highlighted in the recent industry analysis "China’s Top 3 Liquid Cold Plate Manufacturers - Leading the Global Thermal Management Industry," Chinese innovation is at the forefront. Building on that momentum, Guangdong Winshare Thermal Technology Co., Ltd. (Winshare Thermal), a recognized leader profiled in the article, today announces significant advancements in its flagship Brazed Cold Plates technology, engineered specifically to tackle the intense thermal loads of AI servers, power converters, and advanced electric vehicle systems.

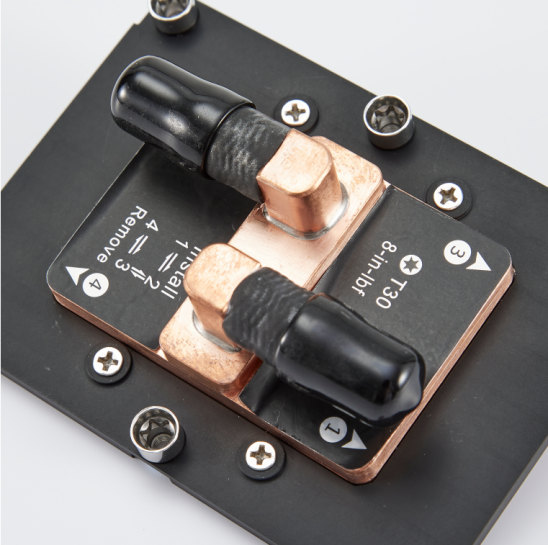

Figure 1: Winshare Thermal's high-performance Brazed Cold Plate, designed for maximum heat flux dissipation in compact spaces.

The Science Behind Superior Brazed Cold Plates

Unlike conventional Liquid Cooling Plate designs, Brazed Cold Plates from Winshare Thermal utilize a vacuum brazing process that fuses multiple layers of high-conductivity aluminum or copper alloys into a monolithic, leak-proof structure. This creates intricate, high-surface-area internal channels that optimize coolant flow and heat transfer. The result is a component capable of handling extreme heat fluxes exceeding 500 W/cm², making it an indispensable solution for direct AI Cooling of GPUs and CPUs in data centers, as well as for IGBTs in fast-charging stations and industrial drives.

"The shift towards Liquid Cooling is irreversible in high-density applications," explains a senior Winshare Thermal R&D engineer. "Our latest brazed technology integrates principles of Mirco Channel Cooling and Jet Cooling into the plate's core architecture. This isn't just incremental improvement; it's a redesign that pushes the limits of what's possible in Water Cooling efficiency and reliability."

A Foundation of Certified Excellence and Vertical Integration

Winshare Thermal's ability to innovate at this level is rooted in its formidable company infrastructure. Since its founding in 2009, the company has focused exclusively on high-power thermal solutions, evolving into a vertically integrated powerhouse. This means complete in-house control over the entire Liquid Cold Plate manufacturing process—from material selection and precision machining to advanced welding and final testing.

Why Winshare Thermal's Manufacturing Edge Matters:

- In-House R&D & Lab: A dedicated heat transfer laboratory and a graduate workstation partnership with South China University of Technology fuel continuous innovation.

- Full Process Control: Self-made key components ensure quality, supply chain stability, and rapid customization from prototype to mass production.

- Global Quality Standards: The company's processes are rigorously certified, including IATF 16949:2016 for automotive-grade quality, ISO 9001:2015 for quality management, ISO 14001:2015 for environmental management, and ISO 45001:2018 for occupational health and safety.

Figure 2: A section of Winshare Thermal's advanced production workshop, showcasing precision manufacturing capabilities.

Comprehensive Liquid Cold Plate Portfolio for Every Challenge

While Brazed Cold Plates represent the pinnacle for high-flux cooling, Winshare Thermal offers a complete ecosystem of Liquid Cooling Plate technologies to match specific application needs:

FSW Cold Plates

Using Friction Stir Welding, these plates offer exceptional strength and leak-proof performance with minimal weight, ideal for aerospace and mobile power systems.

Embedded Tube Cold Plates

A robust and cost-effective Water Cooling solution, perfect for the thermal management of IGBT stacks and large-scale Energy Storage battery packs.

Die Cast & Deep Hole Drilled Cold Plates

Die Cast Cold Plates enable complex, high-volume parts, while Deep Hole Drilled Cold Plates provide ultimate flexibility for cooling irregular heat source layouts.

Driving Global Megatrends with Reliable Thermal Management

Winshare Thermal's solutions are more than just components; they are enablers of global technological progress. From ensuring the reliability of 5G infrastructure and hyperscale AI Cooling data centers to extending the range and safety of electric vehicles, their Liquid Cold Plate technology is embedded in the systems that power modern life. The company's capability to deliver solutions ranging from single modules to container-scale multi-cabinet cooling systems underscores its role as a strategic partner for industry leaders worldwide.

Contact Winshare Thermal for Your Cooling Solution

For engineers and procurement specialists seeking a partner with deep technical expertise, certified manufacturing excellence, and a proven track record in Liquid Cooling, Winshare Thermal offers a compelling advantage.

Explore our full range of Brazed Cold Plates, FSW Cold Plates, Embedded Tube Cold Plates, and other advanced thermal management solutions.

📞 Phone/WhatsApp/WeChat: +86-18025912990

✉️ Email: wst01@winsharethermal.com

🌐 Website: https://www.winsharethermalloy.com

📍 Address: No.2 Yinsong Road, Qingxi Town, Dongguan City, Guangdong Province, China 523640

*This announcement builds upon the market analysis provided in "China’s Top 3 Liquid Cold Plate Manufacturers - Leading the Global Thermal Management Industry," further detailing the technological depth and market leadership of Winshare Thermal.