1. The product is equipped with Siemens CNC system.

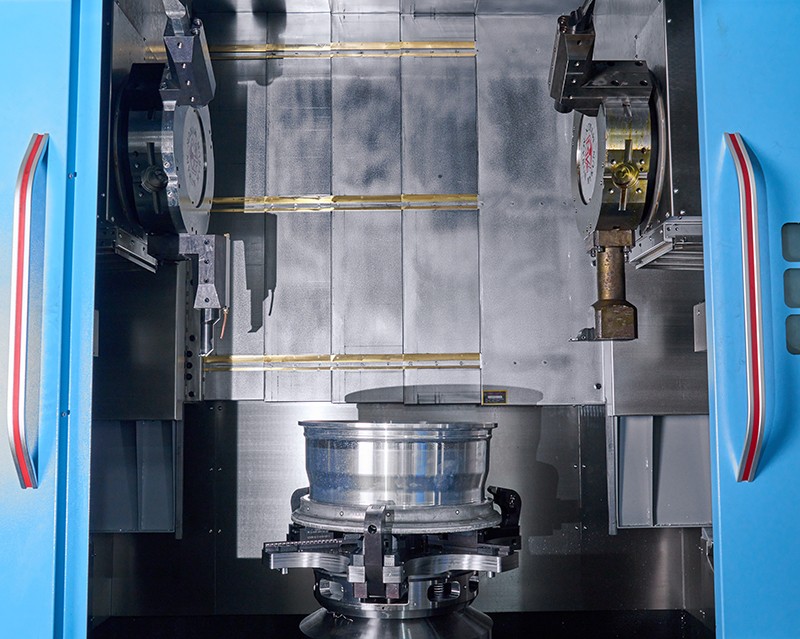

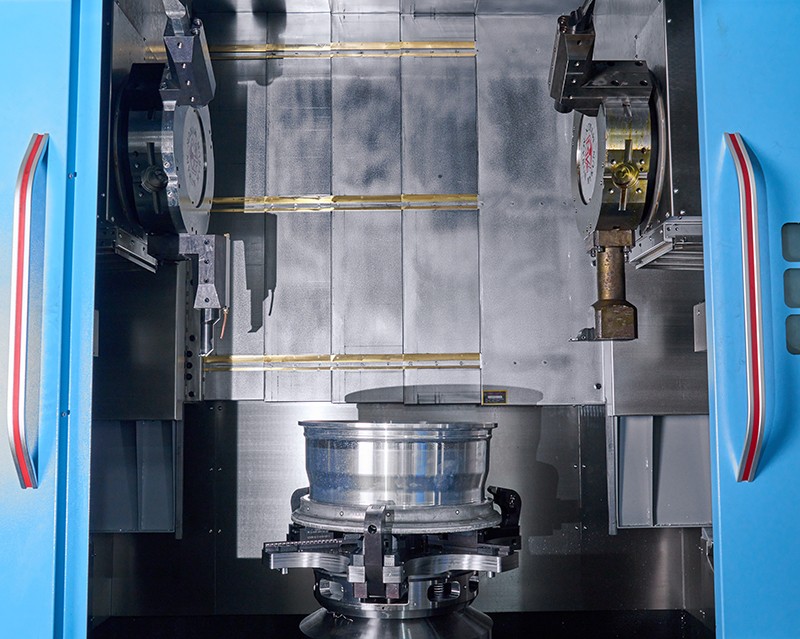

2. The overall layout adopts mechanical, electrical and hydraulic integrated layout to make the whole machine coordinated and consistent.

3. High rigidity and high stability:

* The machine tool adopts symmetrical design and has good thermal stability.

* Integral casting box-type bed.

* The wall plate type column beam and reasonable arrangement of rib plates make it have the characteristics of high strength, high rigidity and high shock absorption.

* The feed unit adopts high-precision ball screw and applies axial preload.

* The resistance type thin oil lubrication system is adopted, and the lubrication points such as each screw and guide rail are lubricated at regular time and quantitatively.

4. High precision and high dynamic response:

* The guide rail adopts four-way equal load heavy-duty roller guide rail. It meets the response speed and provides high rigidity.

* The spindle adopts electric spindle structure.

* The motor and the screw are connected with a diaphragm clamping coupling.

5. High efficiency:

* Spindle speed can reach 2000rpm, Z axis speed can reach 18m/min, X axis 18 m/min.

* Hydraulic turret, fast indexing speed.

6. Good chip removal:

* 45-degree large chip removal ports on both sides of the spindle, combined with large flow of machine flushing, ensure rapid chip removal.

|

LV24W main technical parameters

|

|

project

|

Main parameters

|

|

Processing range

|

Maximum rotation diameter

|

mm

|

Φ850

|

|

Maximum cutting diameter

|

mm

|

Φ680

|

|

Max cutting length/depth

|

mm

|

355/280

|

|

X1/Z1 axis travel

|

mm

|

450/400

|

|

X2/Z2 axis travel

|

mm

|

450/400

|

|

X/Z axis rapid feed

|

m/min

|

20/18

|

|

Spindle

|

Maximum spindle speed

|

rpm

|

2000

|

|

Main motor power (continuous/30min)

|

kW

|

63/80

|

|

Maximum spindle torque (continuous/30min)

|

Nm

|

430/610

|

|

Spindle nose specifications

|

-

|

JISA2-11

|

|

Dota×2

|

Knife Fang

|

mm

|

32*32

|

|

Tool holder type

|

-

|

Hydraulic V6

|

|

|

Boring bar diameter

|

mm

|

φ50

|

|

Tool interface

|

-

|

BMT65

|

|

Cutter change time

|

sec

|

1

|

|

X/Z servo axis motor power

|

kW

|

5.24/5.2

|

|

X/Z servo axis motor torque

|

Nm

|

27/36

|

|

X/Z servo axis motor rated speed

|

rpm

|

2500/2500

|

|

X/Z/axis repeated positioning

|

mm

|

±0.005mm/300mm

|

|

X/Z/axis positioning accuracy

|

mm

|

±0.01

|

|

Spindle end face/radial runout

|

mm

|

0.005/0.005

|

|

Power Requirements

|

kVA

|

100

|

|

Cooling water tank capacity

|

L

|

600

|

|

CNC system

|

-

|

Siemens 828D

|

|

Machine weight

|

kg

|

Approximately 17,000

|

|

Machine dimensions with chip conveyor (length x width x height)

|

mm

|

4430X3620X3325

|