1. The product is equipped with Siemens CNC system.

2. The overall layout adopts the integrated layout of mechanical, electrical and hydraulic, so that the whole machine is coordinated and consistent.

3. High rigidity and high stability:

* The integral casting inclined bed, 45° inclined guide rail, and heavy reinforcement rib design are adopted to minimize distortion and thermal deformation. The wide bed and the guide rails ground after quenching can make the machine tool obtain heavy cutting characteristics and long-term precision retention.

* The spindle box adopts a structural design that reduces thermal deformation to obtain high precision and stable cutting.

* The lubrication system adopts a quantitative pressurized thin oil lubrication system to lubricate each lubrication point such as the lead screw and guide rail at a fixed time and quantity, which improves the stability of the machine tool.

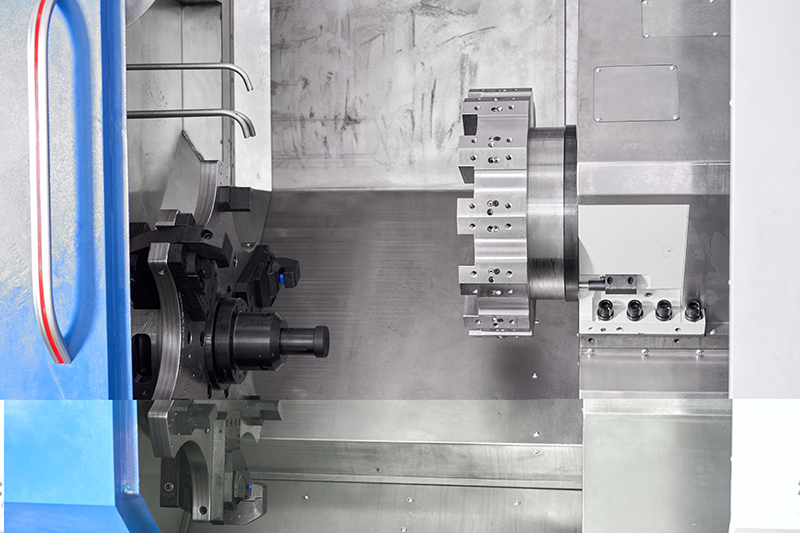

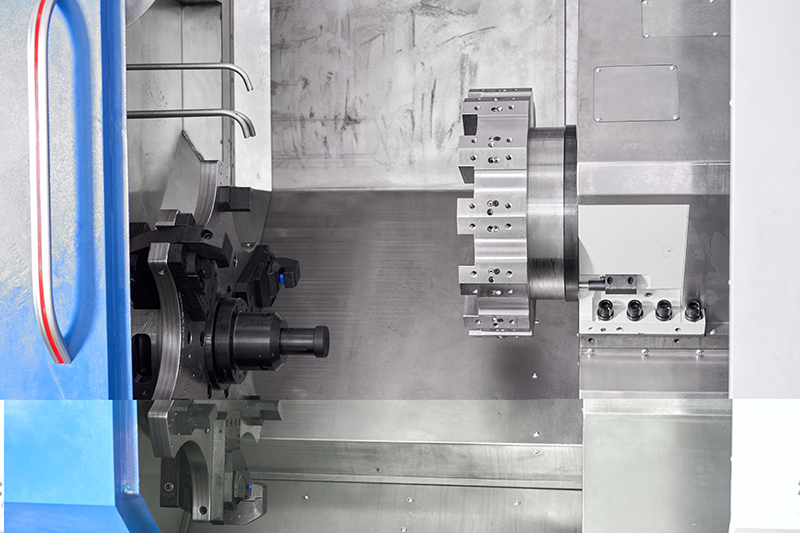

* The large-size 12-bit imported hydraulic turret is suitable for heavy cutting, with strong rigidity, high precision and reliable operation.

* The feed unit adopts a large-diameter ball screw, and pre-tightening is applied at both ends to eliminate the precision loss caused by thermal elongation.

4. High precision and high dynamic response:

*The guide rail adopts four-way equal load heavy-duty roller guide rail. It meets the response speed and provides high rigidity.

*The spindle adopts two-point support, the front end adopts high-precision angular contact ball bearing, and the rear end adopts double-row cylindrical roller bearing support.

*The motor and the lead screw are connected with a diaphragm clamping coupling.

5. High efficiency:

*The maximum spindle speed is 2000rpm, the Z axis is 20m/min, and the X axis is 20m/min.

*Hydraulic turret, fast indexing speed.

6. Good chip removal:

*The bed side discharge, combined with large flow machine flushing, ensures rapid chip removal.

|

LX24W main technical parameters

|

|

project

|

Main parameters

|

|

Processing range

|

Maximum rotation diameter

|

mm

|

φ830

|

|

Maximum cutting diameter

|

mm

|

twenty four"

|

|

Maximum cutting length

|

mm

|

14″

|

|

X-axis travel

|

mm

|

350+35

|

|

Z-axis travel

|

mm

|

850

|

|

X/Z axis rapid feed

|

m/min

|

20/20

|

|

Spindle

|

Maximum spindle speed

|

rpm

|

2500

|

|

Main motor rated power

|

kW

|

52.8

|

|

Spindle rated torque

|

Nm

|

420

|

|

Spindle nose specifications

|

-

|

JISA2-11

|

|

|

|

Spindle journal

|

mm

|

φ160

|

|

Dota

|

Number of tools

|

-

|

12

|

|

Inner diameter knife size (maximum diameter)

|

mm

|

φ50

|

|

Outer diameter tool holder size

|

|

32*32

|

|

Adjacent tool change time

|

sec

|

0.8

|

|

X/Z servo axis motor power

|

kW

|

4.5/4.5

|

|

X/Z servo axis motor torque

|

Nm

|

30/30

|

|

X/Z servo axis motor speed

|

rpm

|

3000

|

|

Cooling water tank capacity

|

L

|

300

|

|

Positioning accuracy

|

mm

|

X

|

Z

|

|

0.008

|

0.01

|

|

Repeat positioning accuracy

|

mm

|

0.004

|

0.005

|

|

CNC system

|

-

|

Siemens

|

|

Machine size (length x width x height) including chip conveyor

|

mm

|

5500X2150X2500

|